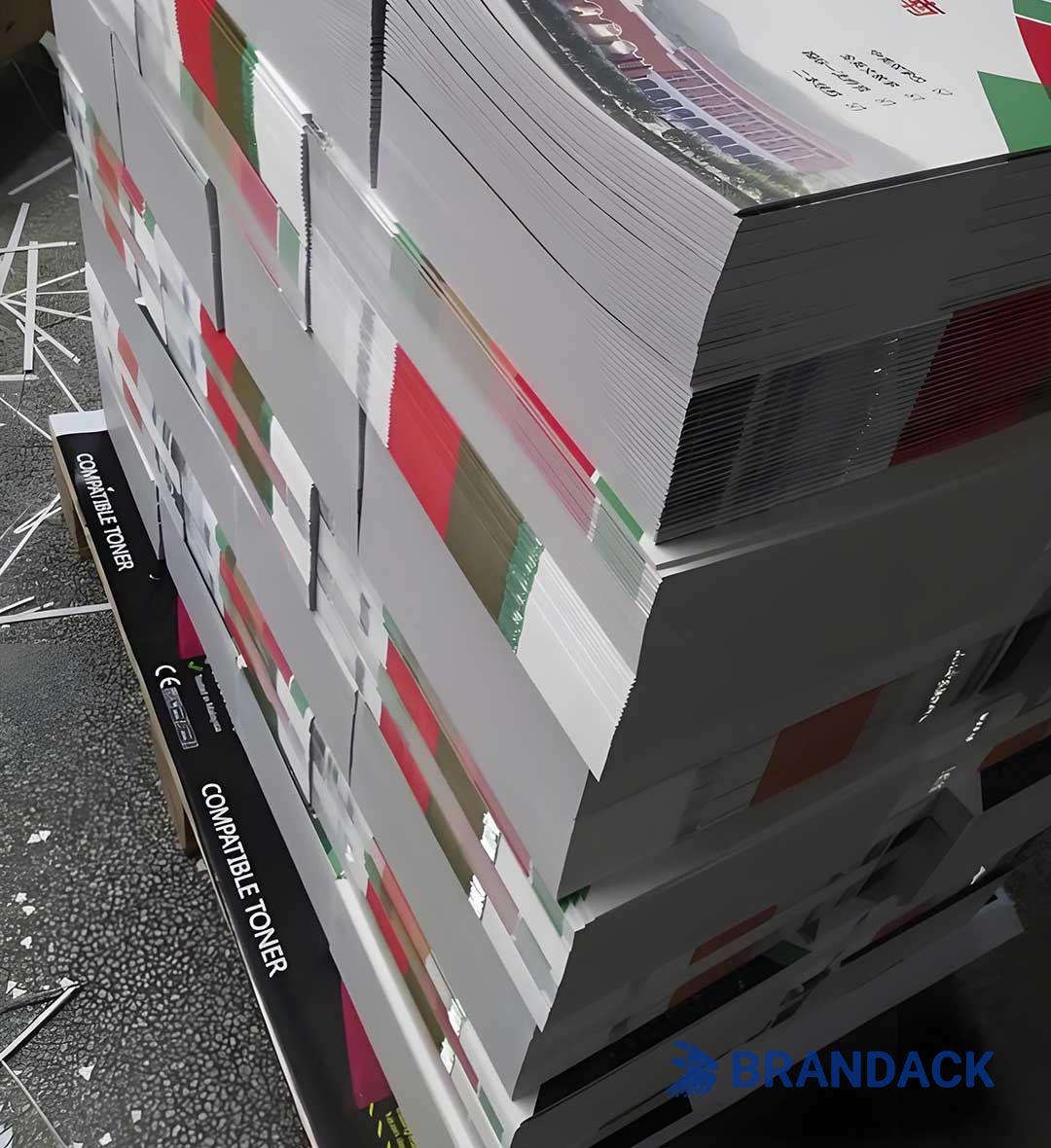

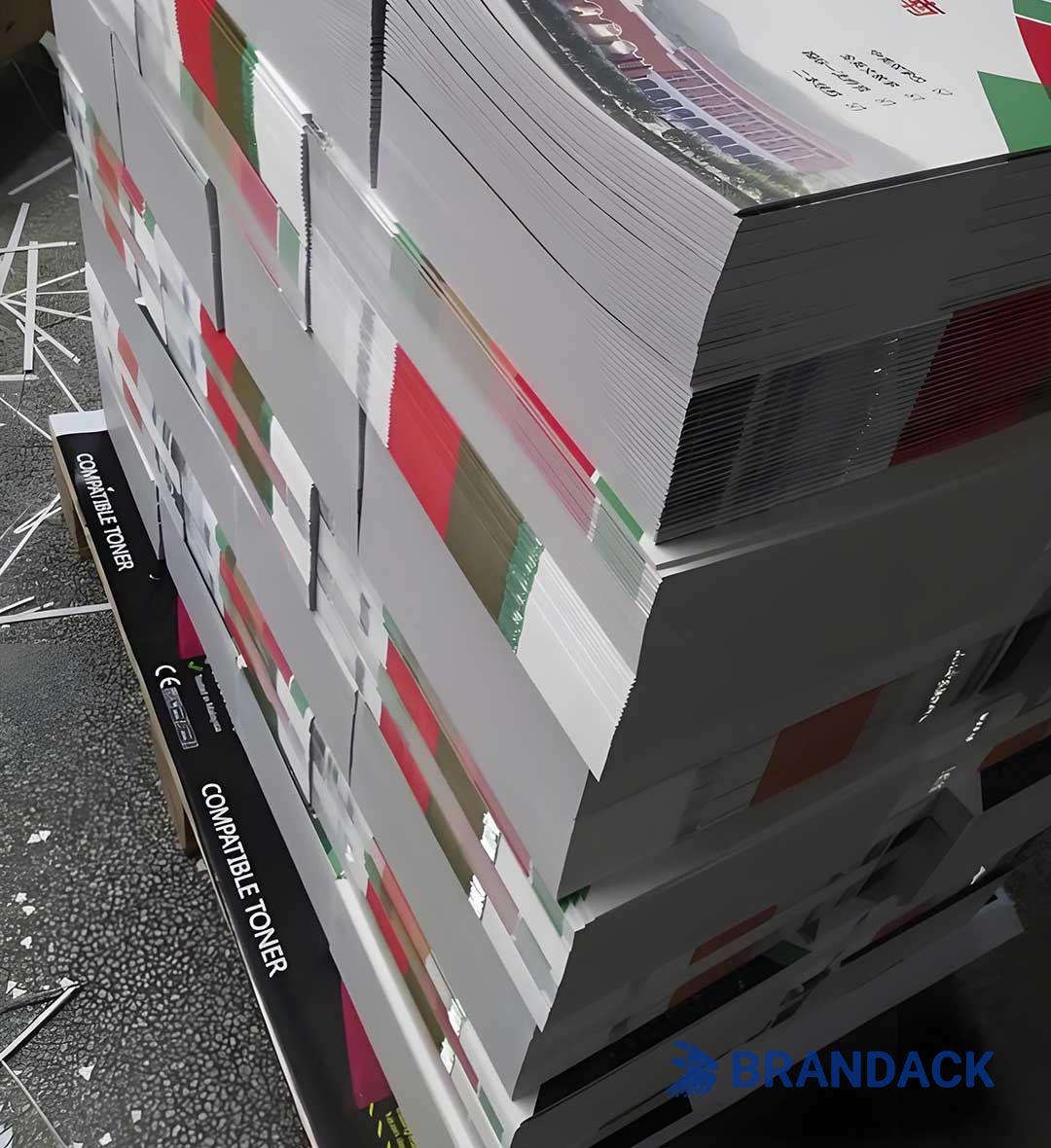

In the printing and packaging industry, even tiny flaws - like a smudged barcode, misaligned color registration, or missing text - can lead to costly rejections, brand damage, or regulatory non-compliance. Traditional manual quality control (QC) relies on human eyes to spot defects, but this approach is fraught with limitations: fatigue causes inconsistent accuracy (Missed detection rate is up to 5-10% for high-volume runs), slow inspection speeds bottleneck production, and subjective judgments make standardization impossible. For brands and converters aiming to deliver flawless packaging, labels, or printed materials, an Automated Print Inspection & Printing Quality Control System isn’t just an upgrade - it’s a necessity.

Core Capabilities: How the System Guarantees Flawlessness

✅ Real-Time In-Line Inspection

Unlike manual checks (which happen post-production, too late to fix issues), the system integrates directly with printing presses (flexo, offset, digital, or gravure). High-resolution cameras (up to 12K) and LED lighting capture every inch of the substrate - whether paper, plastic, metal foil, or film - as it prints. Advanced software analyzes images in milliseconds, flagging defects the moment they occur: ink spots, ghosting, web breaks, incorrect die cuts, or even microscopic text errors.

✅ AI-Powered Defect Classification

Not all defects are equal - and the system knows the difference. Built-in machine learning (ML) algorithms categorize flaws by type (e.g., "color variation," "scratch," "missing QR code") and severity. This eliminates false alarms (a common issue with basic vision systems) and lets operators prioritize fixes: critical defects (like misprinted expiration dates) trigger an automatic press stop, while minor issues (tiny dust specks) are logged for later review.

✅ Data-Driven Quality Assurance

The system acts as a "QC brain," storing every inspection result in a cloud-based dashboard. Users can track key metrics: defect rates per job, most common flaw types, press performance over time, and compliance with standards (e.g., FDA for food packaging, GMP for pharmaceuticals). This data isn’t just for record-keeping - it identifies root causes (e.g., a worn printing plate causing consistent ghosting) to prevent future defects.

✅ Closed-Loop Process Control

For maximum efficiency, the system syncs with press controls. When a defect is detected (e.g., color drift), it sends real-time adjustments to the press - tweaking ink flow, web tension, or registration - without human intervention. This closes the loop between inspection and production, reducing waste (by up to 30%) and ensuring every print run stays on-spec.

Technical Advantages: Designed for Printing & Packaging Challenges

✅ Material Adaptability: It works with glossy, matte, transparent, or textured substrates - adjusting lighting and image analysis to avoid false defects from substrate glare or texture.

✅ High-Speed Performance: Inspects up to 1,000 feet of web per minute, matching the speed of modern printing presses without slowing production.

✅ Customizable Inspection Rules: Brands can set unique standards (e.g., "QR code must scan 100% of the time," "color match to Pantone 185C ±0.5ΔE") - the system tailors check to specific job requirements.

✅ Remote Access: Operators and managers can monitor QC in real time from any device (laptop, tablet), ideal for multi-site facilities or remote troubleshooting.

Industry Applications: Flawlessness Across Use Cases

✅ Food & Beverage Packaging: Ensures no ink migration (a safety risk), clear nutrition labels, and intact seals - critical for FDA/USDA compliance.

✅ Pharmaceutical Packaging: Eliminates errors in drug names, dosages, or batch numbers (preventing costly recalls) and verifies tamper-evident features.

✅ Retail Labels & Tags: Guarantees scannable barcodes, accurate pricing, and consistent brand colors - protecting brand identity on store shelves.

✅ Folding Cartons: Checks for clean die cuts, proper glue seams, and no crease defects - ensuring cartons fold correctly and look professional.

Tangible Benefits: Beyond "Flawless" - Business Value

Quality: 99.99% Defect Detection Rate: Far exceeds manual QC, reducing rejected batches and customer complaints.

Efficiency: 25-40% Faster Production: No more stopping presses for manual checks; real-time adjustments cut downtime.

Cost Savings: Up to 35% Less Waste: Fewer scrapped materials and reprints, plus reduced labor costs (1 system replaces 2-3 QC inspectors).

Compliance: Audit-Ready Records: Automatic data logging simplifies regulatory audits (e.g., ISO 9001, FDA 21 CFR Part 11).

Competitive Edge: Consistent Branding: Flawless packaging builds trust with retailers and consumers, setting your business apart.

Beyond Inspection: Building Trust and Brand Value

In an industry where "good enough" leads to lost business, an Automated Print Inspection & Printing Quality Control System is the foundation of reliability. It turns subjective, slow manual checks into precise, real-time quality assurance - ensuring every print, label, or package leaves your facility flawless. For converters and brands ready to eliminate defects, cut costs, and protect their reputation, this system isn’t an expense - it’s an investment in long-term success.

Our Automated Print Inspection System is more than a piece of hardware - it's a strategic partner in excellence. It safeguards your clients' brands and, by extension, reinforces your reputation as a quality-driven supplier committed to delivering perfection, time after time.

Embrace a future of flawless printing. Let’s talk about how our automated quality control system can become the cornerstone of your quality assurance program.

Contact us today to schedule a demo and see flawless in action.