For businesses investing in printing or packaging - whether for product boxes, marketing materials, or brand collateral - choosing between offset and digital printing can impact cost, quality, and turnaround time. This guide breaks down their core differences, ideal uses, and how to pick the right method for your project.

What Is Offset Printing?

Offset printing uses plates to transfer ink onto a rubber blanket, which then applies the image to paper or other materials. It’s renowned for its:

Superior Color Accuracy: Ideal for projects requiring exact Pantone matches.

Cost-Effectiveness for Large Runs: Lower per-unit cost for high volumes.

High Image Quality: Sharp details and consistent results.

Versatility on Materials: Works on paper, cardboard, metal, and more.

Offset Printing Is Best For:

Large-quantity jobs (e.g., catalogs, packaging boxes, magazines).

Projects needing special inks or finishes (e.g., spot UV, foil stamping).

What Is Digital Printing?

Digital printing transfers designs directly from digital files to substrates using toner or liquid ink. Its advantages include:

Quick Turnarounds: No plates needed, reducing setup time.

Cost-Efficiency for Short Runs: Affordable for small batches.

Customization: Easily personalize each piece (e.g., variable data printing).

Proofing Flexibility: Ideal for rapid prototypes and revisions.

Digital Printing Is Best For:

Short runs (e.g., samples, limited editions).

Time-sensitive projects (e.g., event materials).

Personalized prints (e.g., branded merchandise, direct mail).

Key Differences: Side-by-Side

The table below highlights critical factors that matter for packaging and printing projects:

Factor | Offset Printing | Digital Printing |

Setup Time | Long (1 - 2 days for plate-making, calibration) | Short (minutes - just upload your file) |

Cost Structure | High upfront costs (plates, setup); lower per-unit cost for large runs | Low upfront costs; higher per-unit cost for large runs |

Quality & Color | Superior color accuracy (matches Pantone standards), sharp details, and consistent ink coverage - ideal for vibrant packaging. | Excellent color consistency for short runs; may struggle with ultra-fine details or specialty inks (e.g., metallic) on thick substrates. |

Substrate Compatibility | Works with most materials: cardboard, plastic, metal, glass, and textured papers (critical for packaging like rigid boxes or gift bags). | Limited to smoother substrates (e.g., coated paper, thin cardboard); may not adhere well to rough or non-porous materials. |

Personalization | No variable data - all pieces are identical (e.g., 10,000 identical cereal boxes). | Full variable data support (e.g., 500 gift boxes with unique customer names or batch numbers). |

Turnaround Time | Slow (1 - 5 days for setup + printing) | Fast (same-day or next-day for short runs) |

Ideal Applications

Choose based on your project’s goals, volume, and design needs:

When to Use Offset Printing

Offset excels at large-volume, high-quality projects where consistency and material flexibility matter - perfect for packaging:

✅ Bulk product packaging: E.g., 10,000+ cardboard shipping boxes, 5,000 plastic food containers, or 20,000 cosmetic tubes.

✅ High-end marketing materials: Glossy magazines, billboards, or premium catalogs (needs sharp images and Pantone color matching).

✅ Specialty substrates: Rigid gift boxes, metal tins, or textured paper bags (offset adheres better to non-smooth surfaces).

When to Use Digital Printing

Digital is best for small-batch, personalized, or time-sensitive projects:

✅ Custom packaging samples: Test 50 - 500 prototype boxes before full production (fast, low-cost iterations).

✅ Small-batch brand collateral: 100 - 1,000 personalized direct mailers (with unique addresses) or limited-edition product labels.

✅ Last-minute projects: Rush orders for event signage or pop-up shop packaging (same-day turnaround possible).

How to Choose the Right Method

Ask these 3 questions to decide:

1. What’s your run size?

<500 units: Digital Printing (avoids offset’s upfront costs).

1,000 units: Offset Printing (lower per-unit cost).

2. Do you need personalization?

Yes (e.g., unique QR codes on packaging): Digital Printing.

No (all pieces identical): Offset Printing (more cost-effective).

3. What substrate are you using?

Rough/non-porous (e.g., metal, thick cardboard): Offset Printing.

Smooth/standard (e.g., coated paper, thin cardboard): Digital Printing.

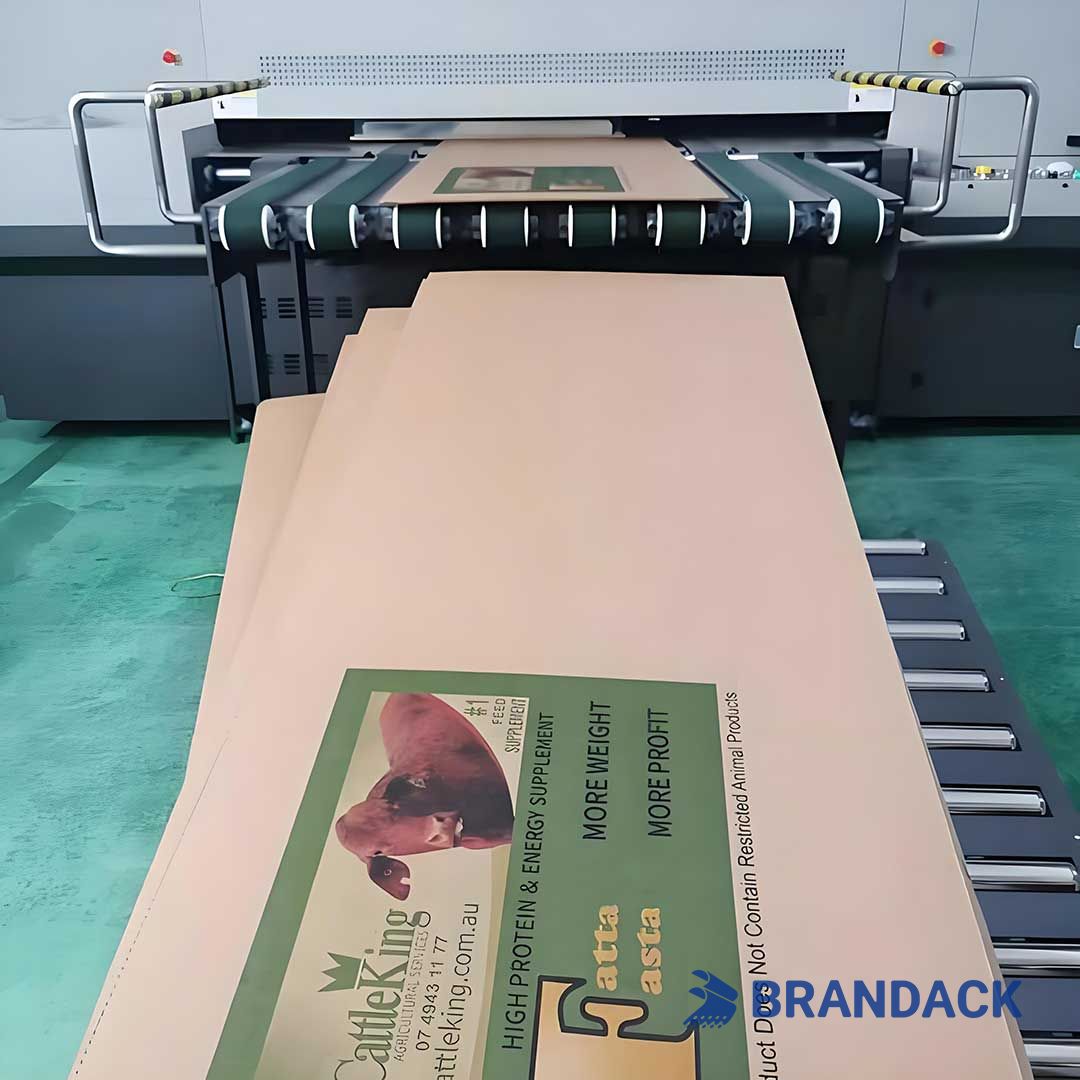

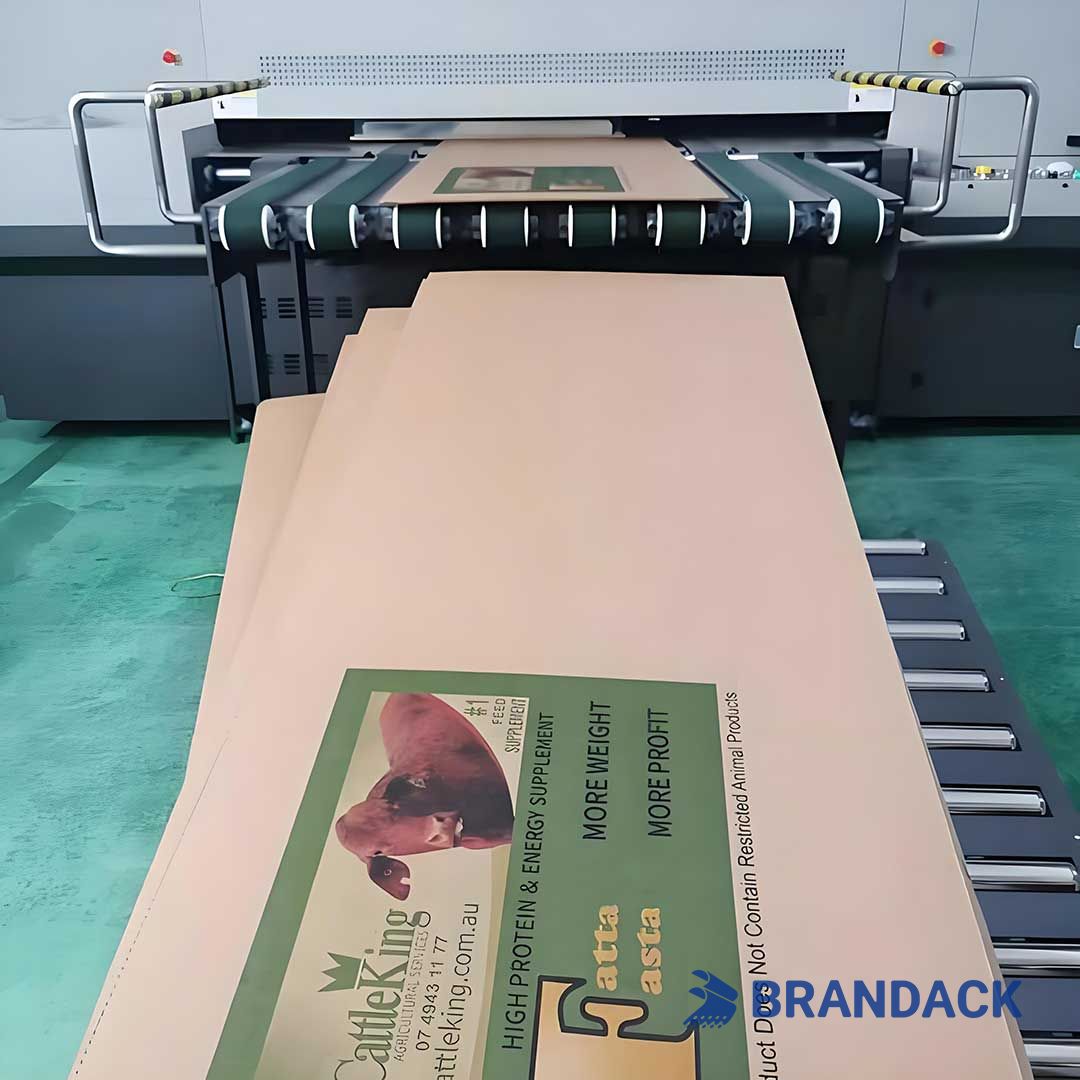

Why Choose BRANDACK?

We combine the best of both worlds:

✦ State-of-the-Art Technology: Advanced offset and digital presses for flawless output.

✦ Expert Guidance: Help you select the ideal method for your project’s scale, timeline, and budget.

✦ End-to-End Solutions: From design to finishing (e.g., cutting, coating, binding).

Partner With Us for Tailored Solutions

At BRANDACK, we don’t just offer printing - we help you choose the method that fits your budget, timeline, and brand goals. Whether you need 10,000 offset-printed product boxes or 200 digital-personalized gift tags, our team ensures crisp, consistent results every time.

Contact our experts today to discuss your project!