Welcome to our Knowledge Base - where innovation meets expertise. If you're deciding between UV printing and digital printing for your upcoming project, you're in the right place. Both technologies offer unique advantages, but understanding their differences is key to achieving the perfect result. Let’s break it down.

What Is Digital Printing?

Digital printing is a modern method that transfers digital-based designs directly onto materials. It’s fast, cost-effective for small to medium runs, and perfect for projects requiring high detail and quick turnaround. Think of it as the go-to solution for:

Custom packaging prototypes

Marketing materials (brochures, flyers)

Short-run product labels

Personalized prints

Its flexibility and speed make it ideal for projects where adaptability and efficiency are priorities. However, it may have limitations in durability and material compatibility compared to specialized techniques like UV printing.

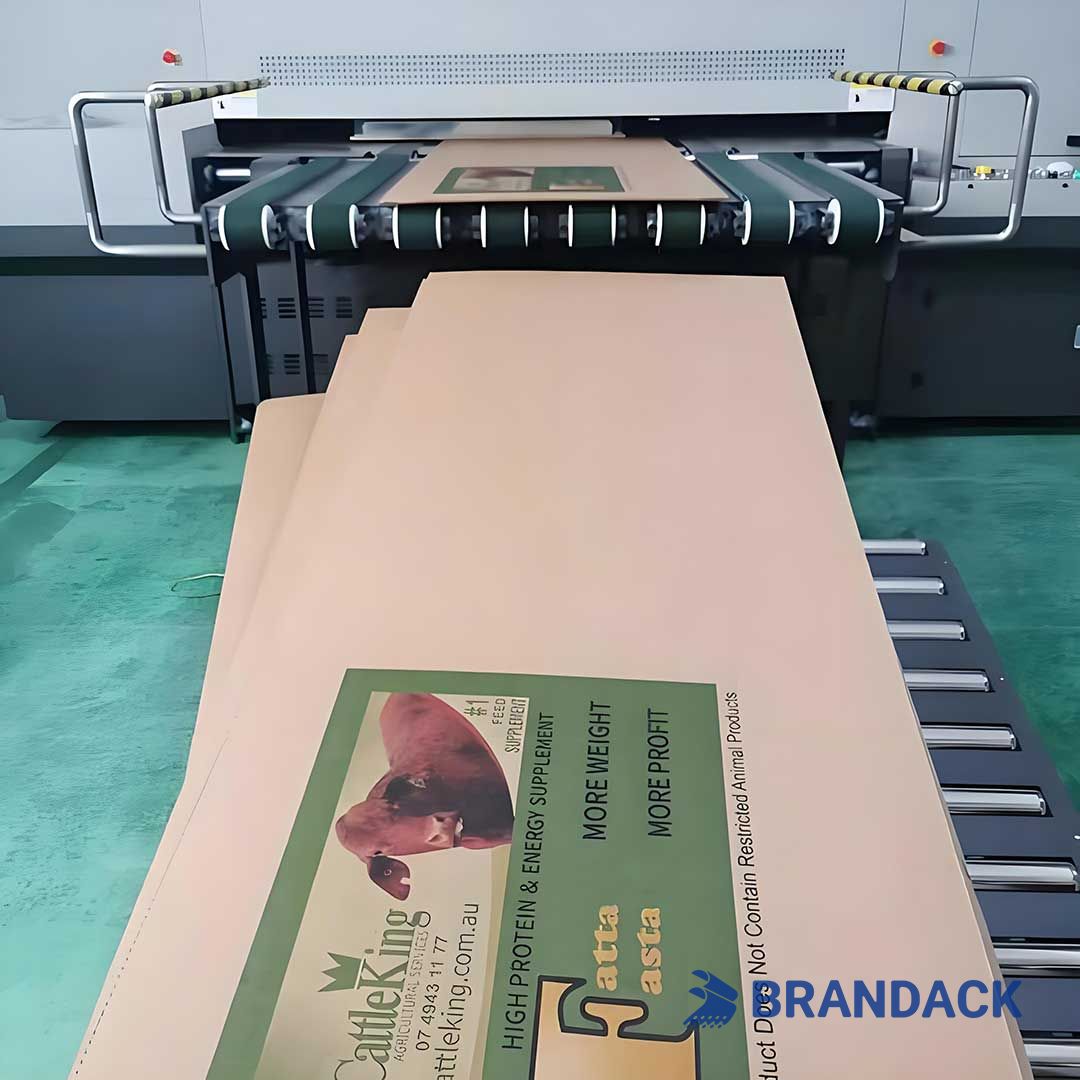

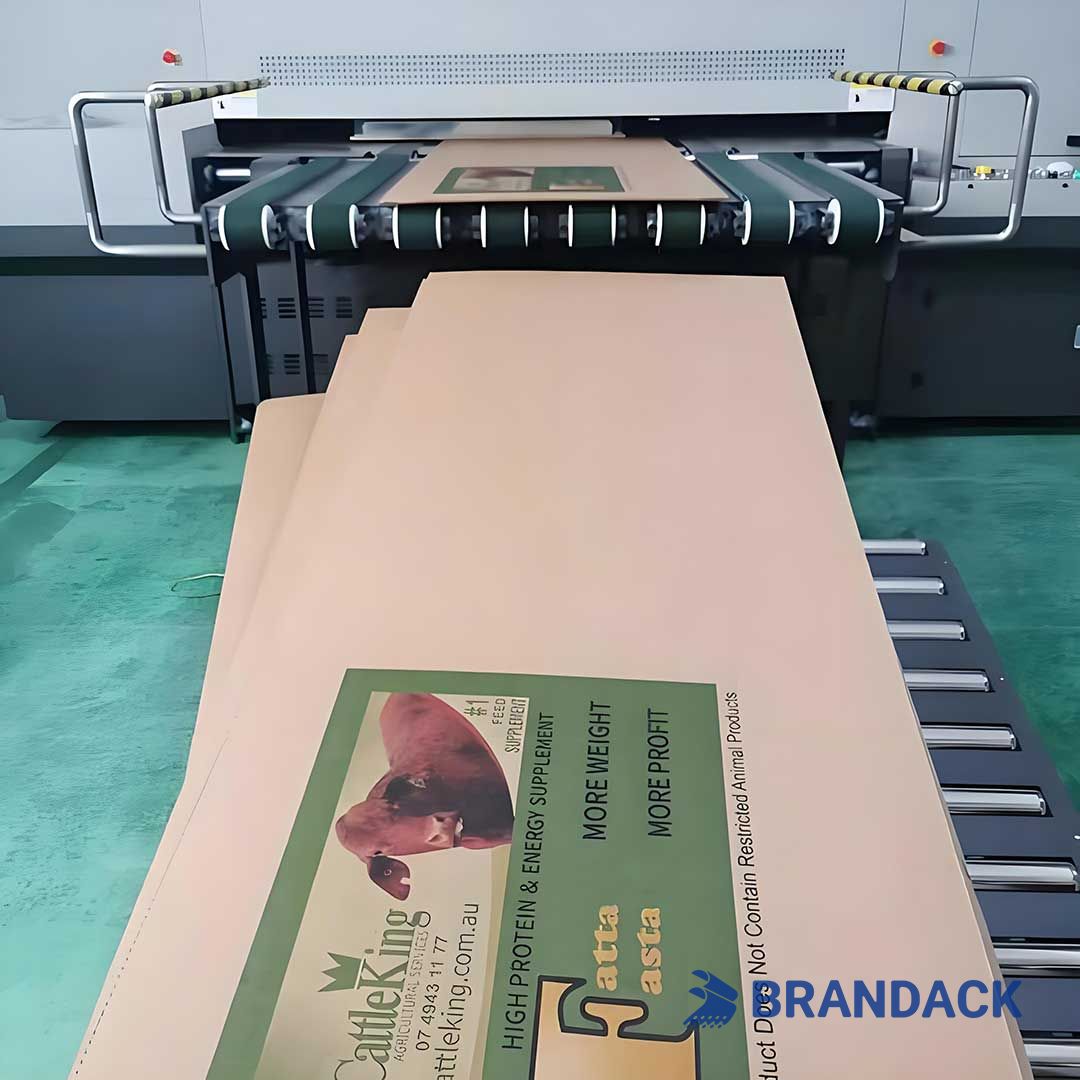

What Is UV Printing?

UV printing uses ultraviolet light to instantly cure inks as they’re printed onto surfaces. This process creates a durable, high-resolution finish that resists fading, scratching, and moisture. It’s a game-changer for:

Products exposed to outdoor elements

Rigid materials (wood, acrylic, metal, glass)

High-impact packaging requiring extra resilience

Designs with vibrant colors and fine details

UV printing excels in versatility and durability, making it the premium choice for projects that demand longevity and a standout finish.

Key Differences at a Glance

We’ve focused on the factors that make or break packaging success-material fit, durability, cost, and more:

P Material Compatibility: UV printing works on almost any substrate - even non-porous ones. Digital printing is best for paper, cardstock, and flexible materials.

P Durability: UV printing offers superior resistance to wear and environmental factors.

P Turnaround Time: Digital printing is faster for low-quantity jobs.

P Cost: Digital is more economical for short runs; UV provides greater value for specialized, long-lasting applications.

P Eco-Friendliness: UV printing has a lower VOC emission and energy footprint compared to some traditional methods.

Factor | UV Printing | Digital Printing |

Material Compatibility | Shines on non-porous materials: plastic, metal, glass, acrylic, and coated cardstock. Perfect for rigid packaging (e.g., cosmetic jars, metal tins). | Best for porous materials: paper, uncoated cardstock, and thin films. Works on some coated plastics but may need post-coating for durability. |

Durability | Highly durable: UV inks resist scratches, water, UV rays, and temperature changes. Great for outdoor packaging or items that need long shelf life (e.g., garden product boxes). | Less durable alone: Inks may smudge if wet or fade in sunlight. Requires lamination or varnishing for long-term use (adds time/cost). |

Color Performance | Vibrant, high-contrast colors (e.g., bold logos on dark plastic). Can print white ink (critical for opaque designs on clear materials like PET bottles). | Excellent color consistency for small batches. Struggles with ultra-bright hues or white ink on dark substrates. |

Cost Structure | Higher setup cost (UV lamps, specialized inks). Cheaper per unit for large batches (500+ units) - setup costs spread across more items. | Low setup cost (no plates). Cheaper for small batches (1-500 units). Per-unit cost stays steady (no savings with larger runs). |

Turnaround Time | Fast for large batches (once setup is done). Slow for small runs (setup time outweighs print speed). | Instant setup: Fastest for small batches or last-minute tweaks (e.g., adjusting a design for a limited-edition package). |

Design Flexibility | Great for 3D textures or raised effects (e.g., embossed logos on luxury boxes). Less ideal for frequent design changes (setup rework). | Perfect for frequent design updates or variable data (e.g., different regional labels on the same product). Limited textural options. |

Which Should You Choose?

✦ For urgency and small batches: Digital printing is your best bet.

✦ For durability and material diversity: UV printing is the winner.

Still unsure? Our team is here to help! We provide tailored solutions based on your project’s scale, material, timeline, and vision.

Why Choose Us?

With state-of-the-art UV and digital printing technologies, we combine speed, quality, and creativity to bring your ideas to life. Explore our Knowledge Base to learn more - or contact us for a personalized consultation today!

Let’s create something remarkable together.