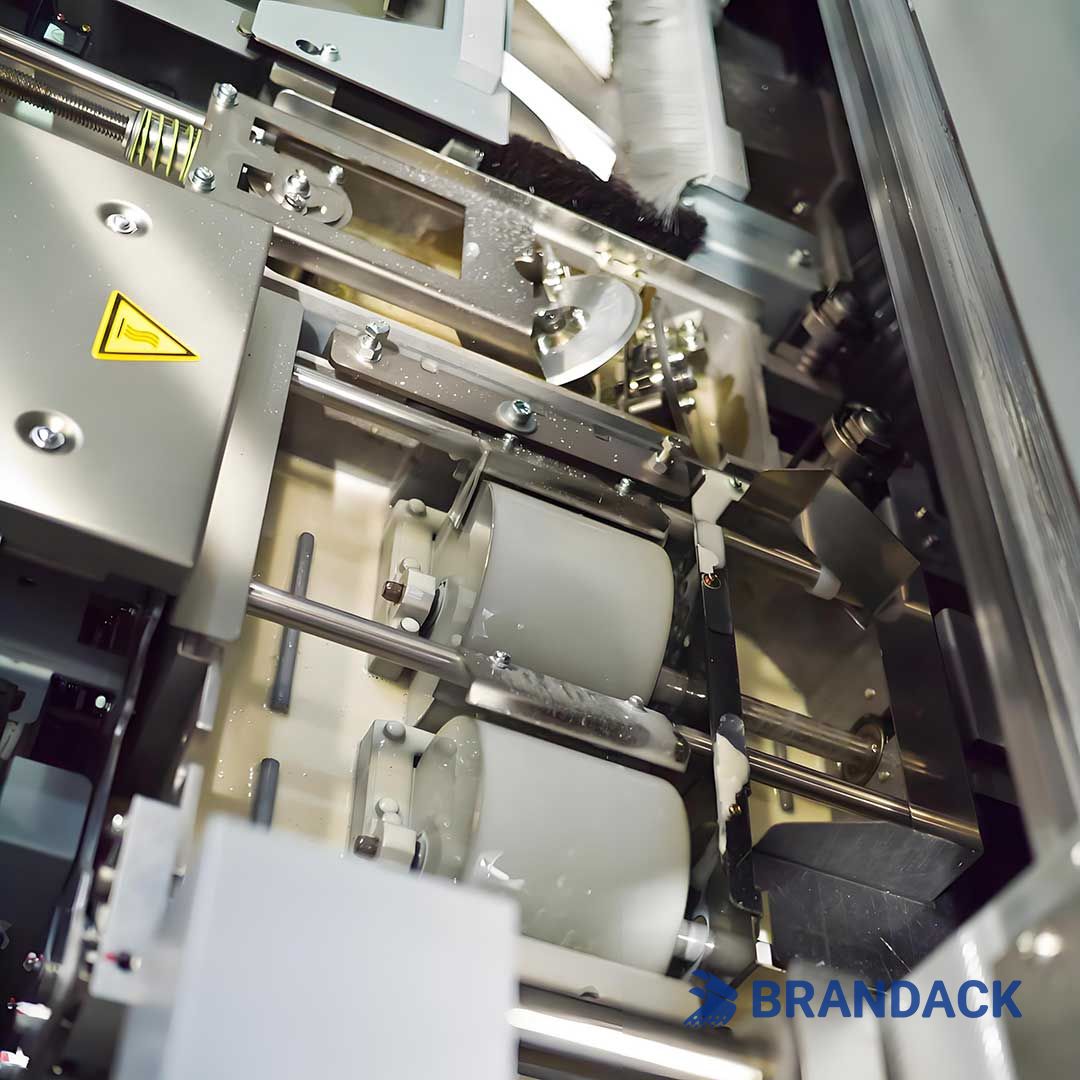

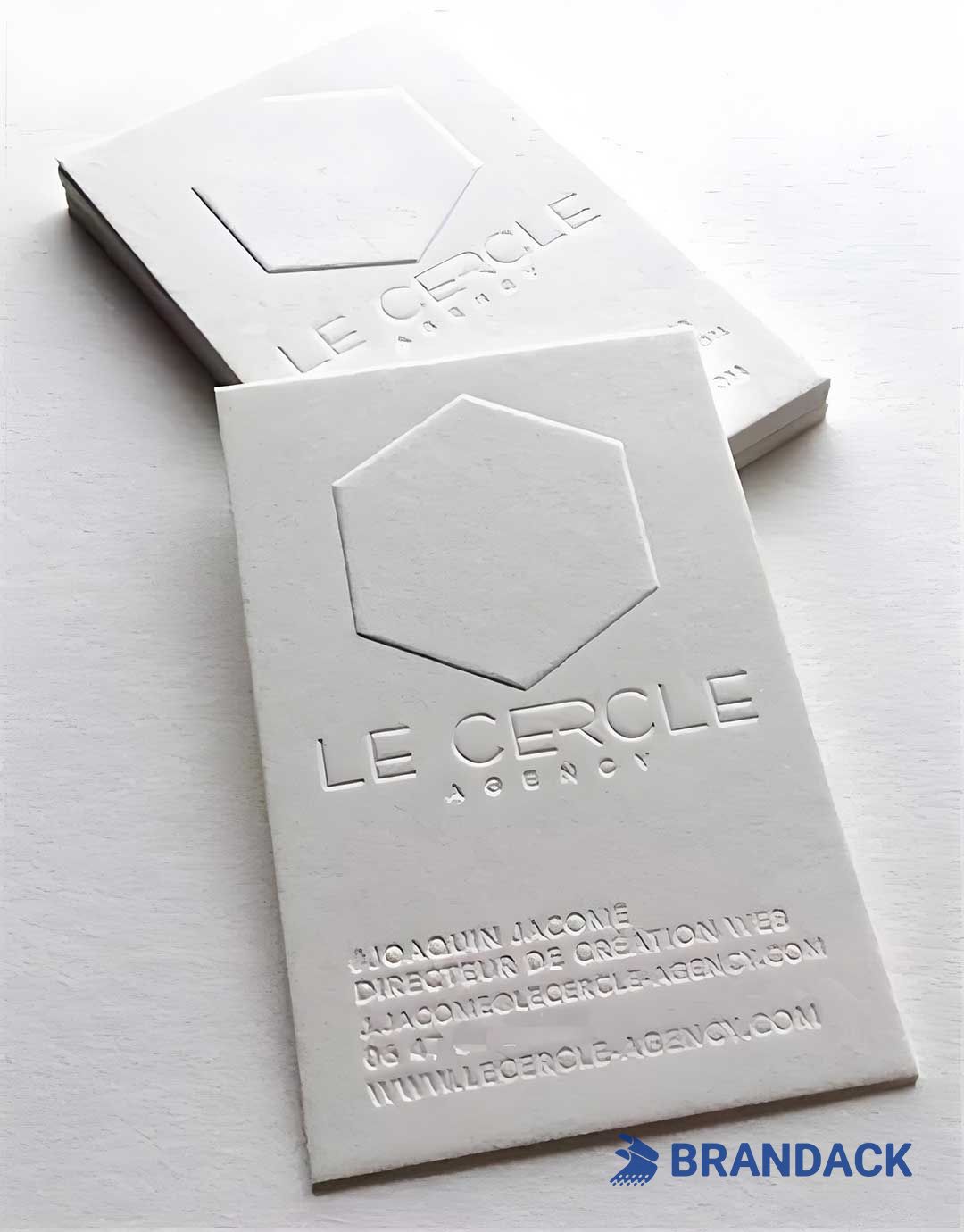

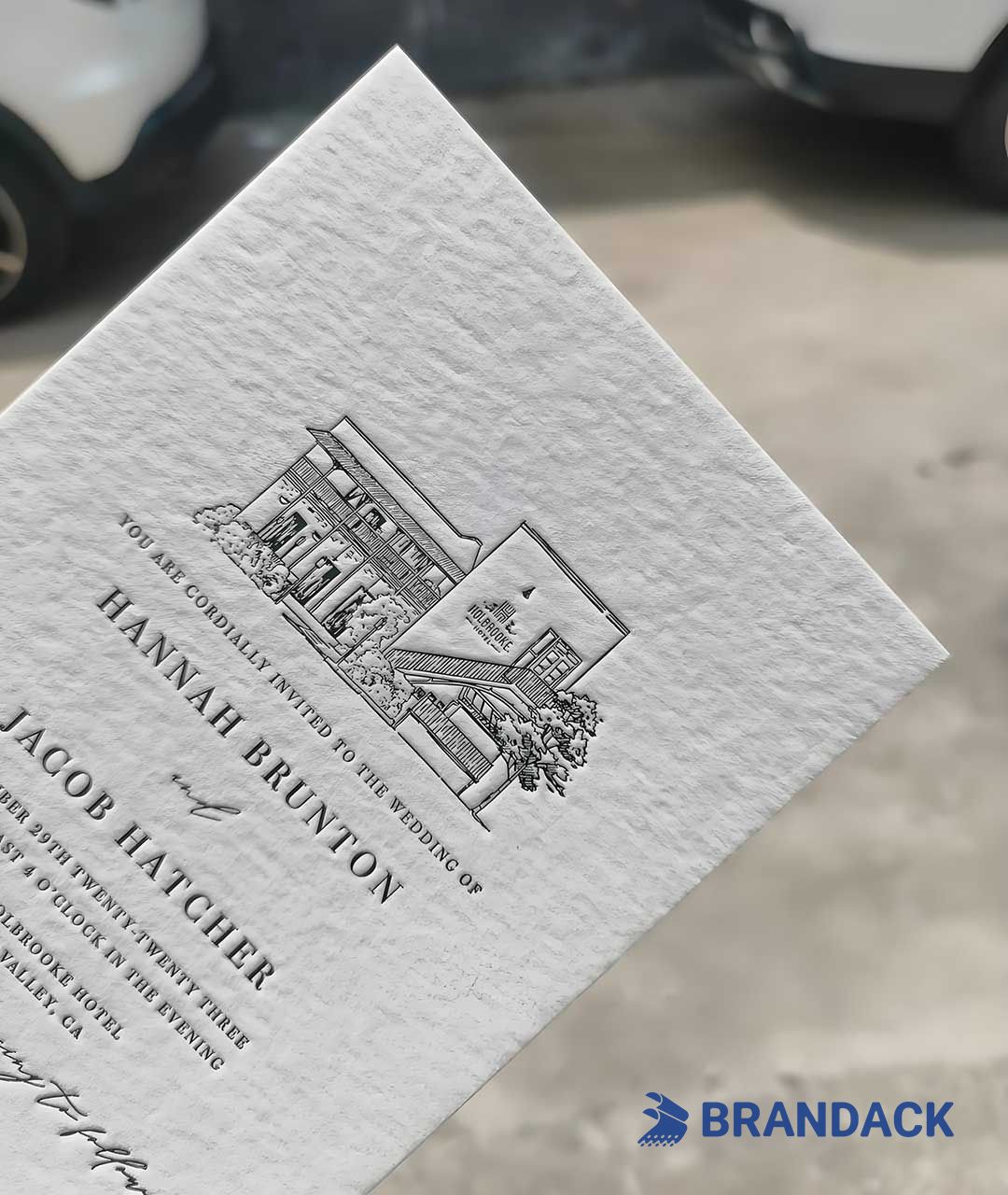

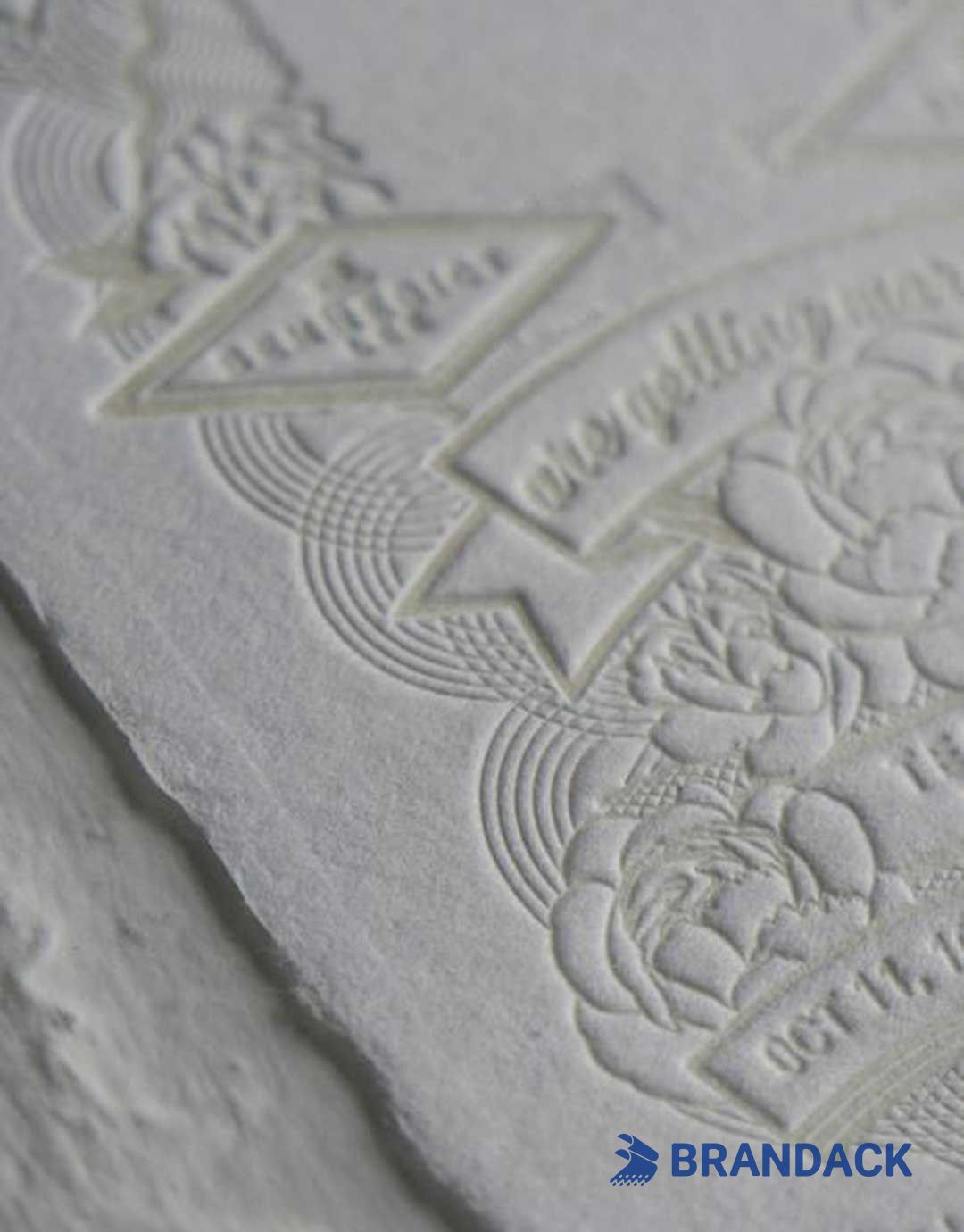

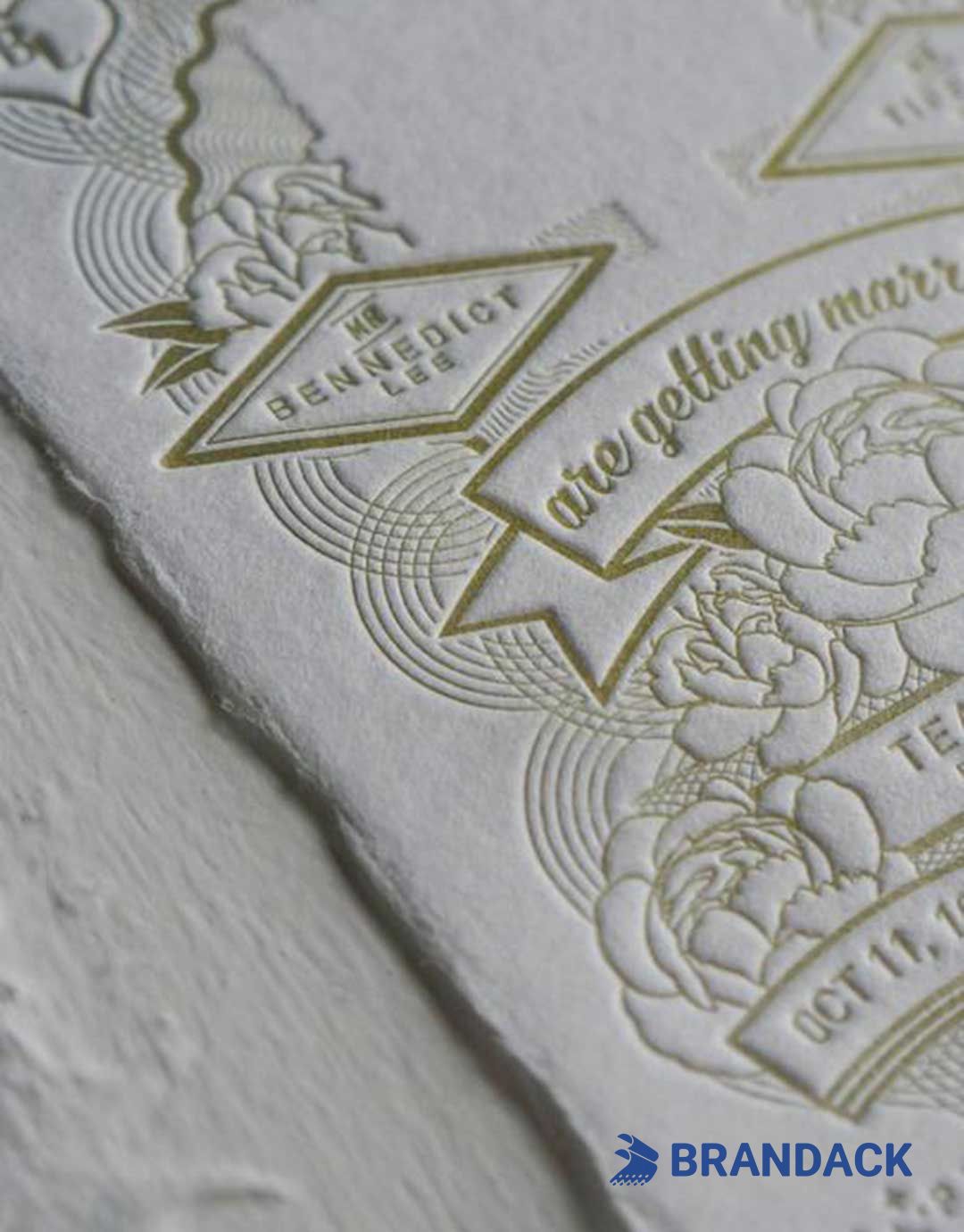

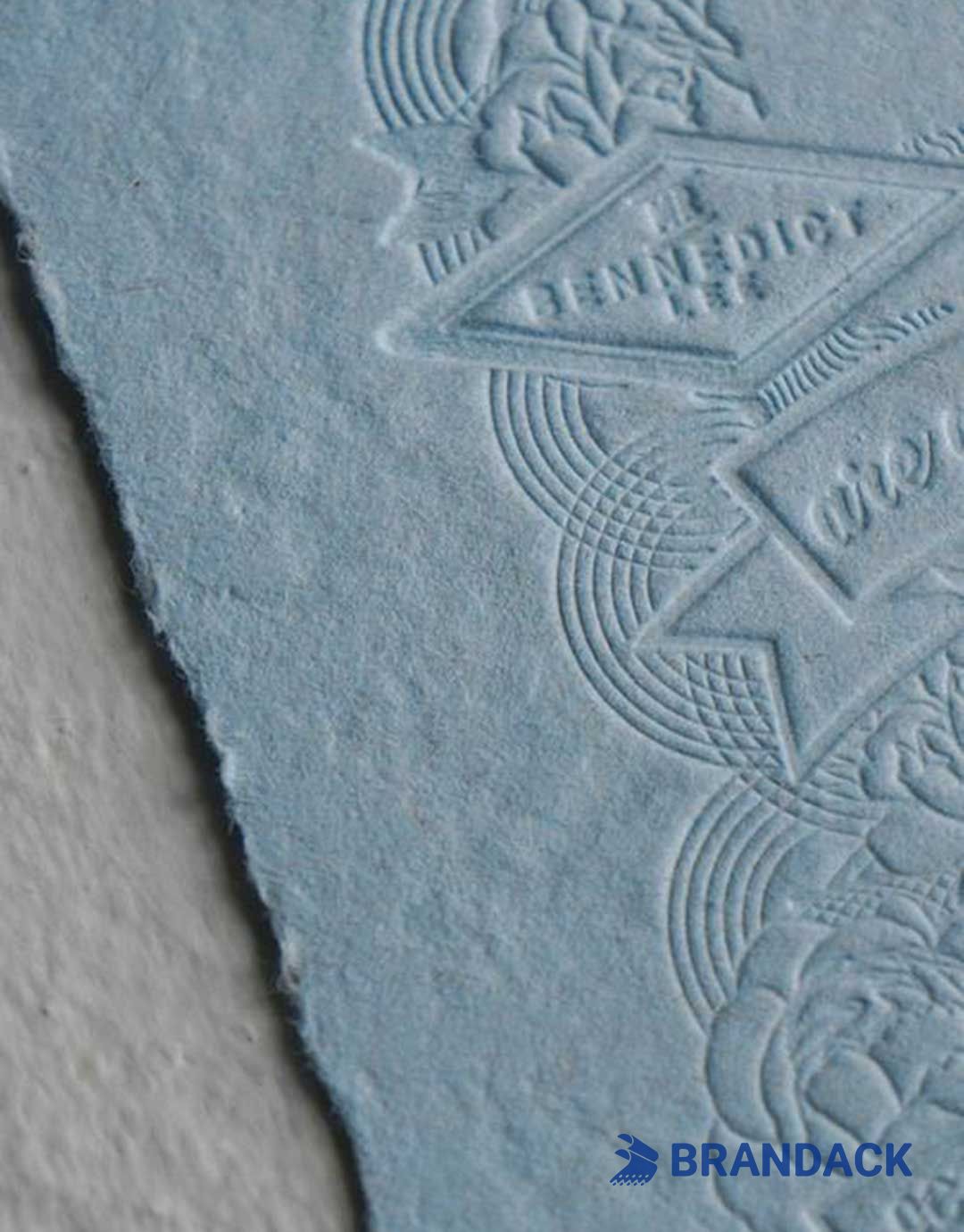

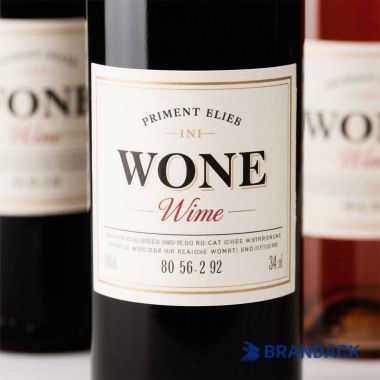

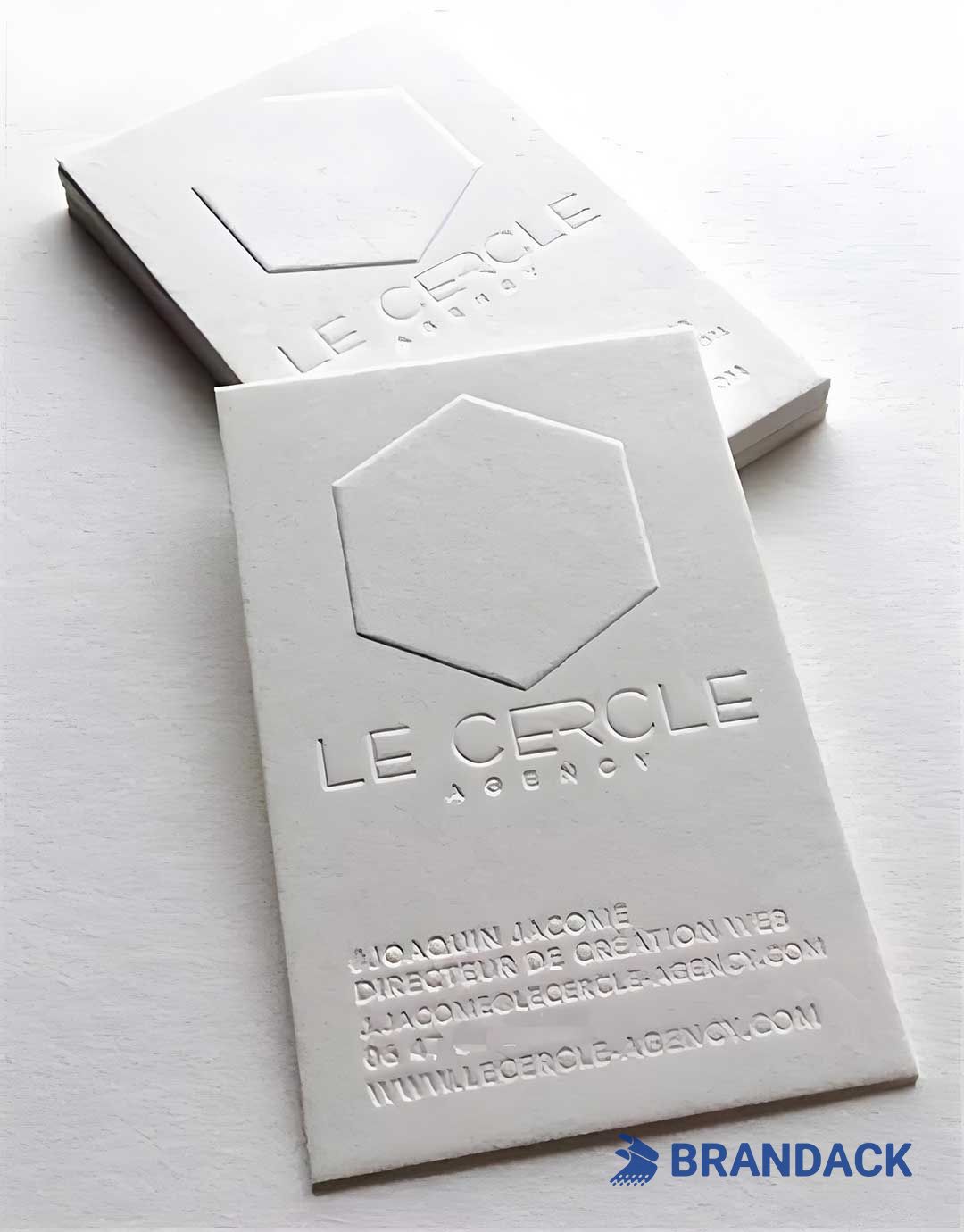

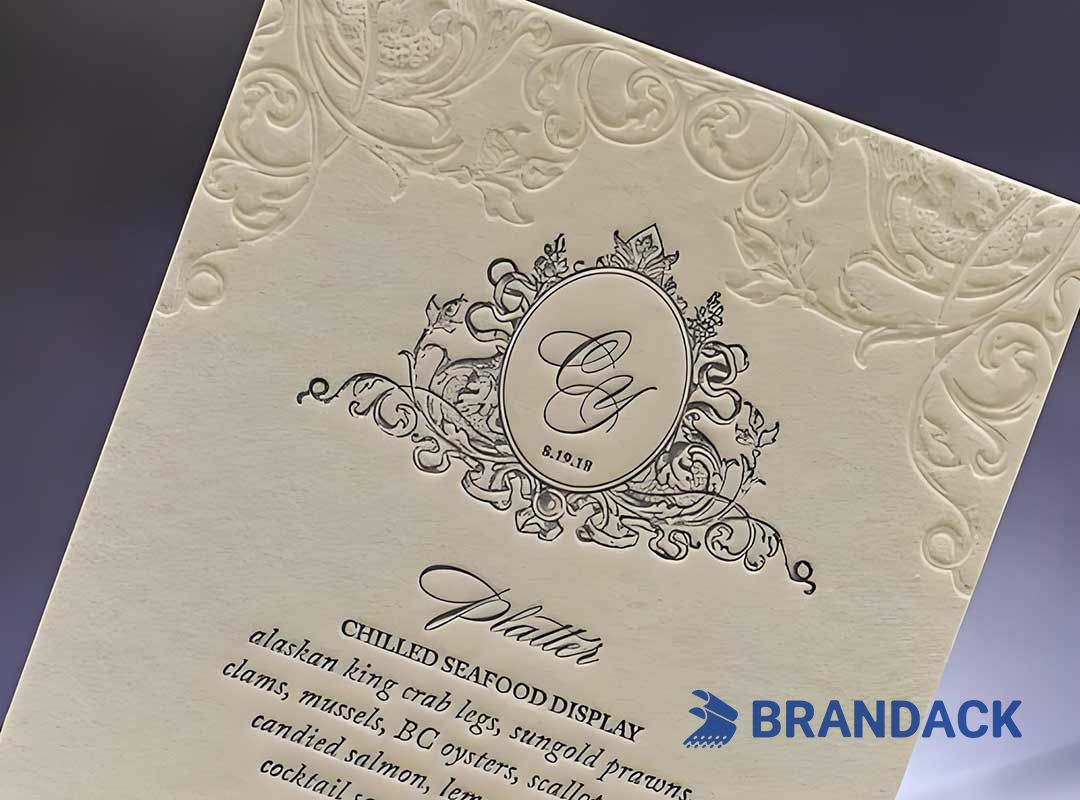

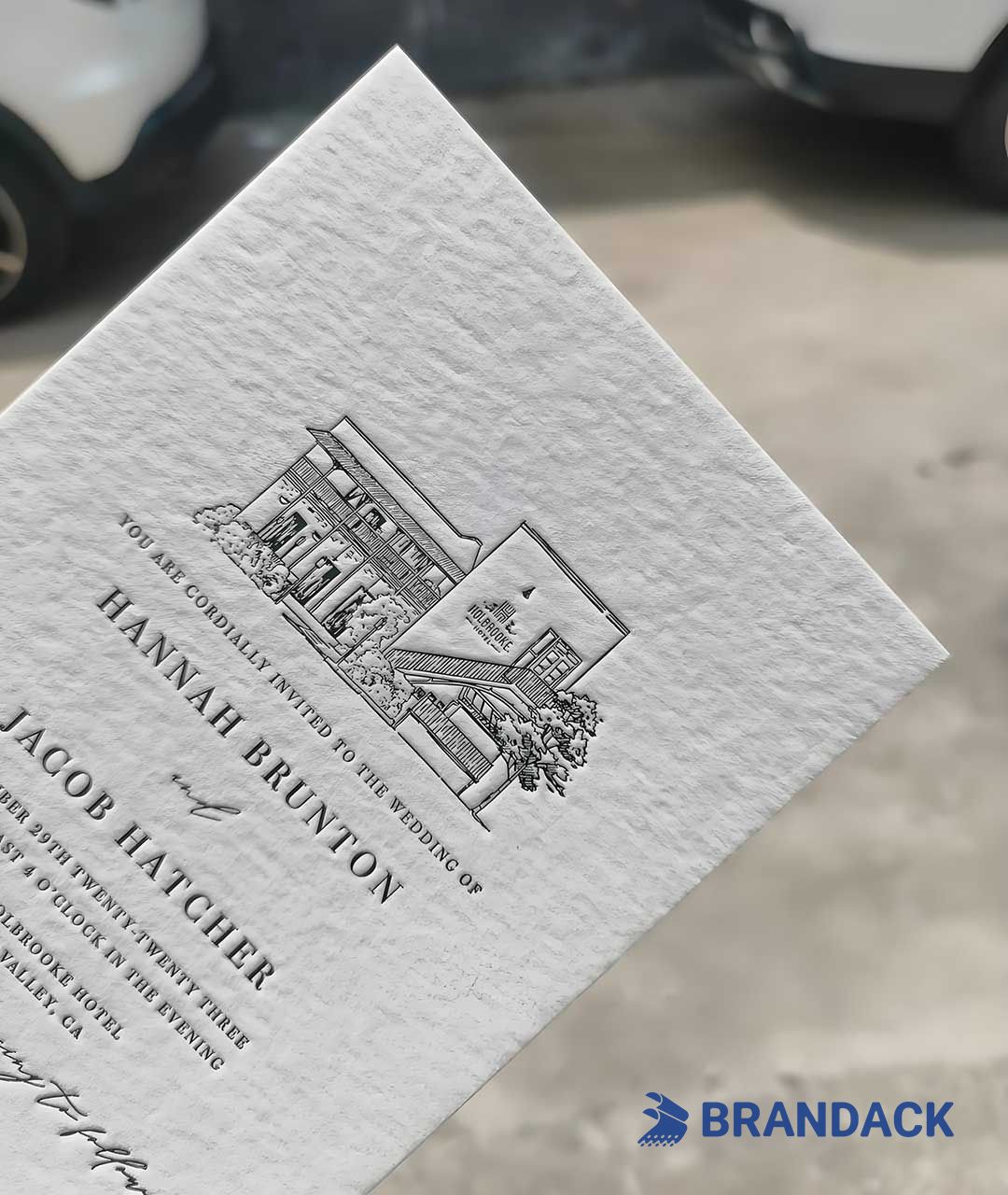

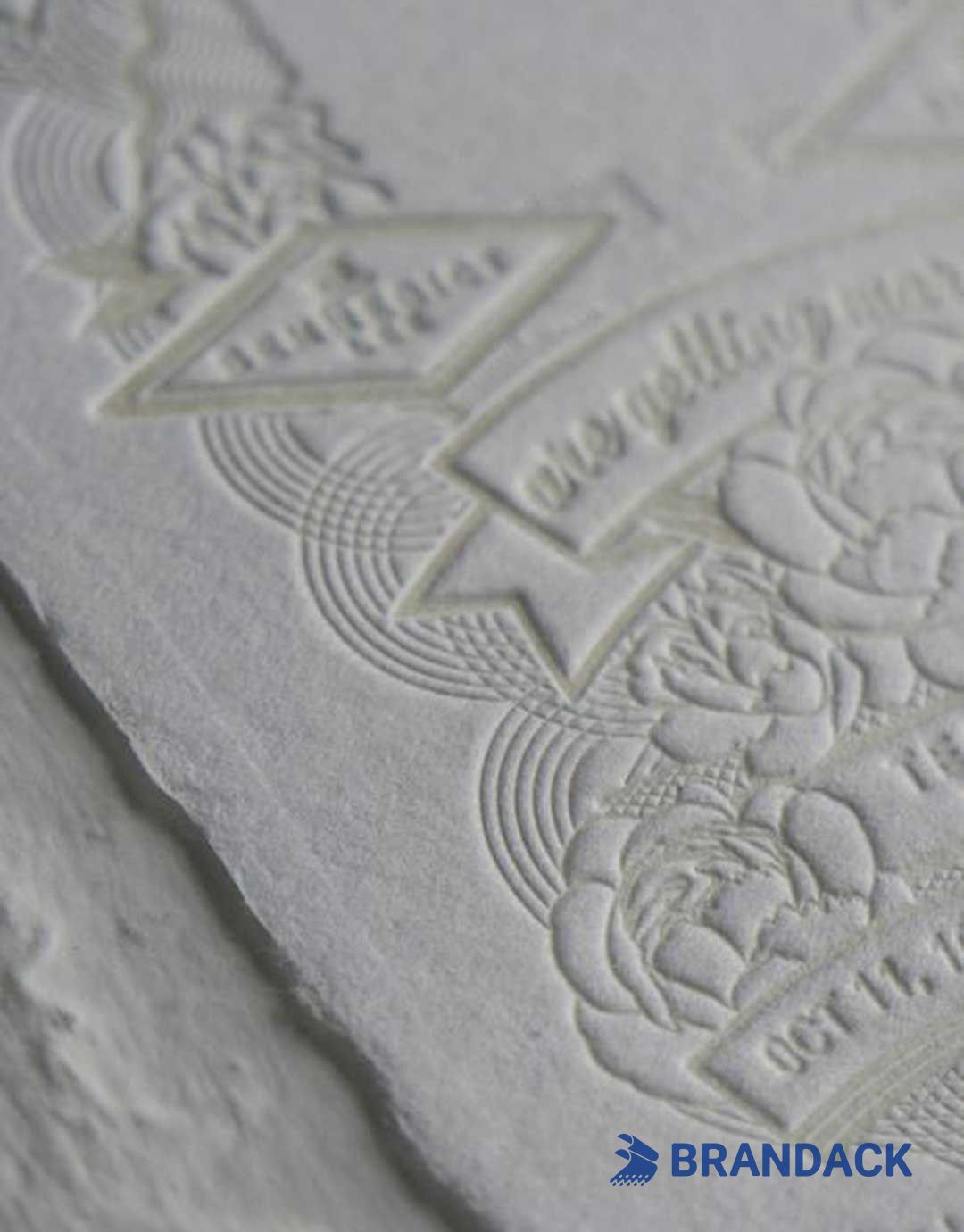

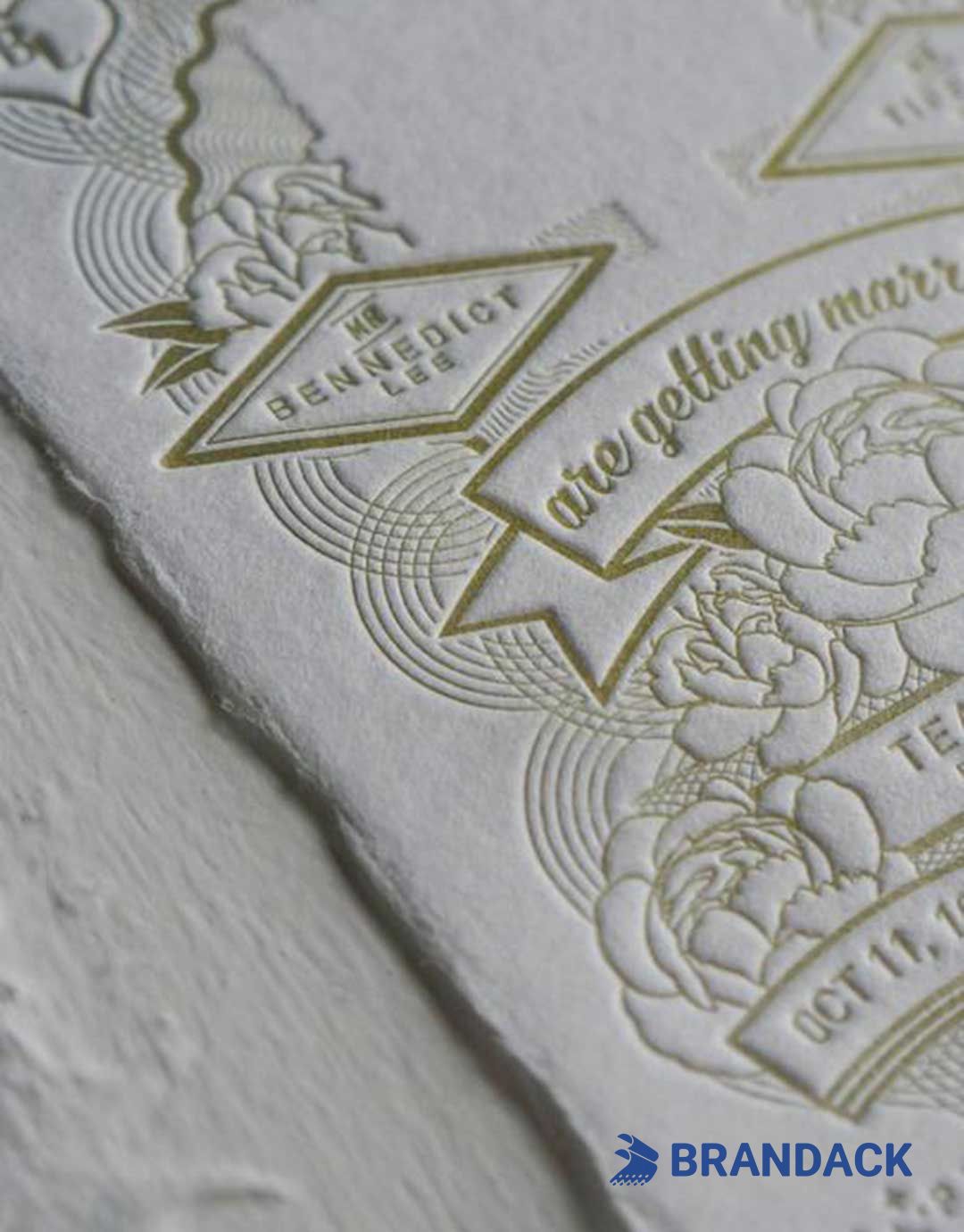

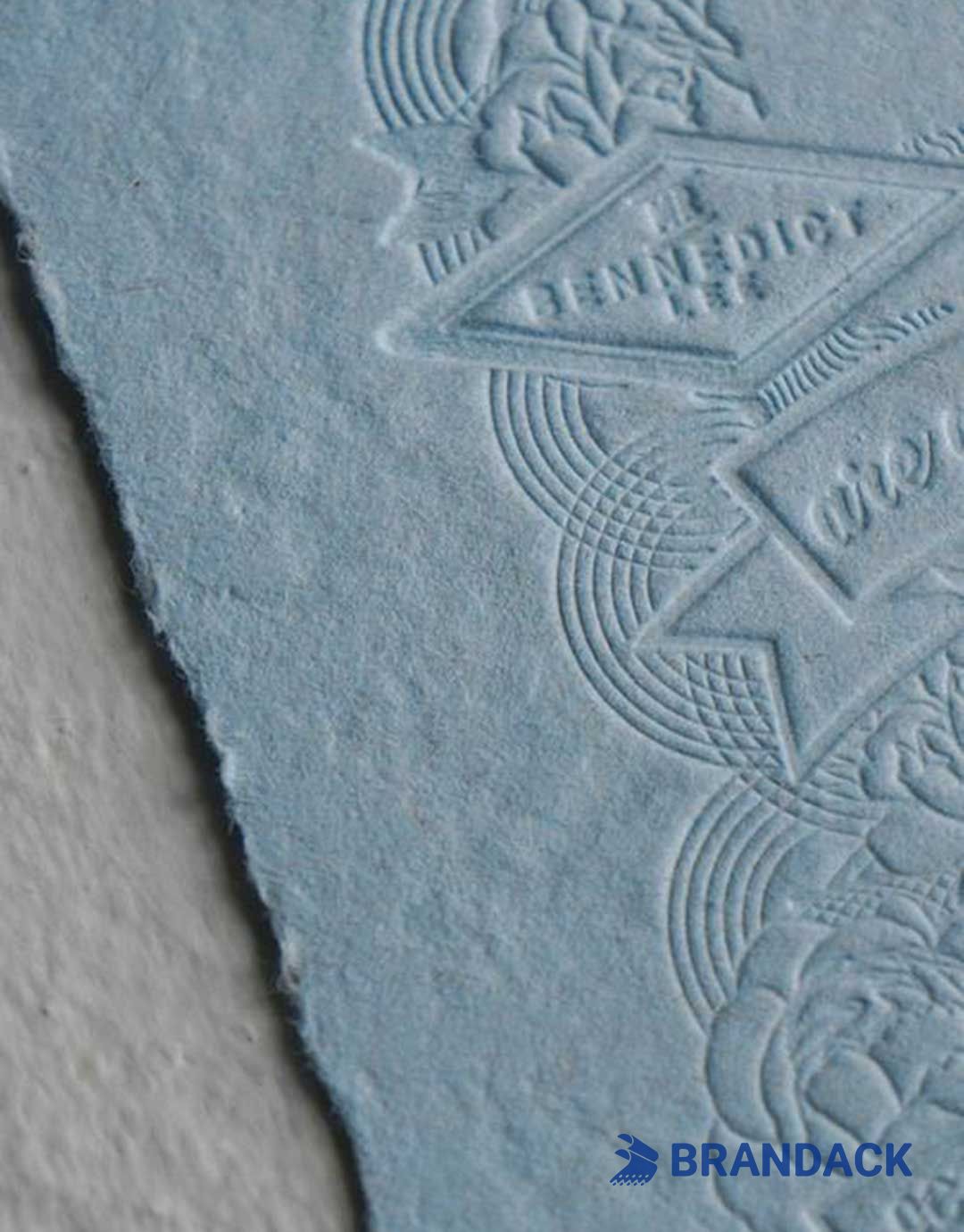

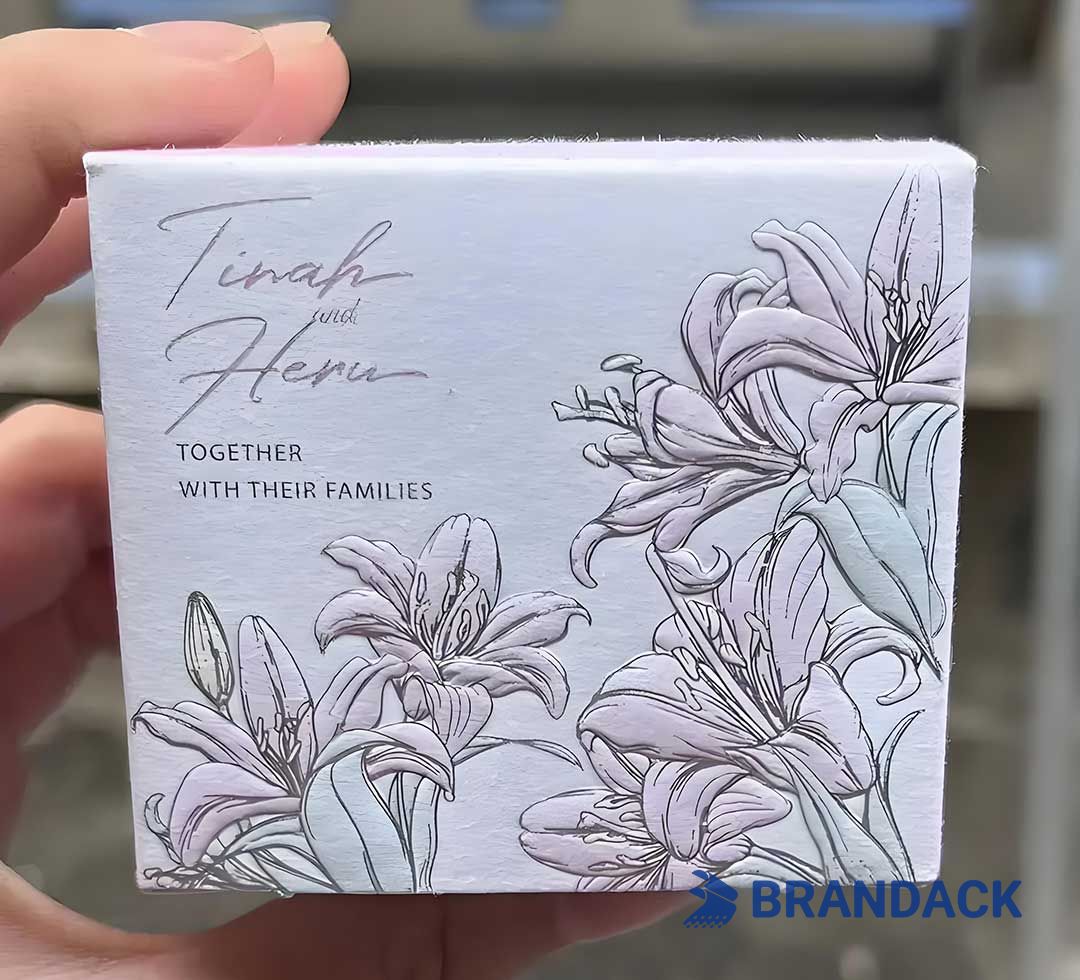

In the world of printing and packaging, letterpress printing (a classic relief printing technique) stands out for its tactile, premium finish - making it ideal for luxury brands, artisanal packaging, wedding stationery, and high-end marketing materials. Unlike digital printing, letterpress printing uses raised plates to press ink into paper, creating a subtle embossed texture that elevates brand perception. Below is your go-to guide for understanding its essentials, navigating custom workflows, and solving common challenges.

Letterpress Printing Essentials

To achieve consistent, high-quality letterpress results, master these core components:

Materials: The Foundation of Great Results

✅ Paper: Opt for thick, textured stocks (100-300 lb cover weight) like cotton, linen, or kraft. Thin or smooth papers may tear under pressure or fail to show the signature letterpress texture. Avoid coated papers (e.g., glossy cardstock) as they resist ink absorption.

✅ Ink: Use oil-based or soy-based letterpress inks - they dry slowly enough for even coverage but adhere well to paper. For food packaging, choose FDA-approved, low-VOC (volatile organic compound) inks to meet safety standards.

✅ Plates: Two primary options:

✅ Metal plates (brass, magnesium): Durable for large runs (5,000+ pieces) and sharp detail.

Resin plates: Cost-effective for small-batch custom projects (500-2,000 pieces) and quick turnaround.

Equipment: Tools for Precision

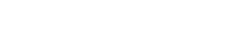

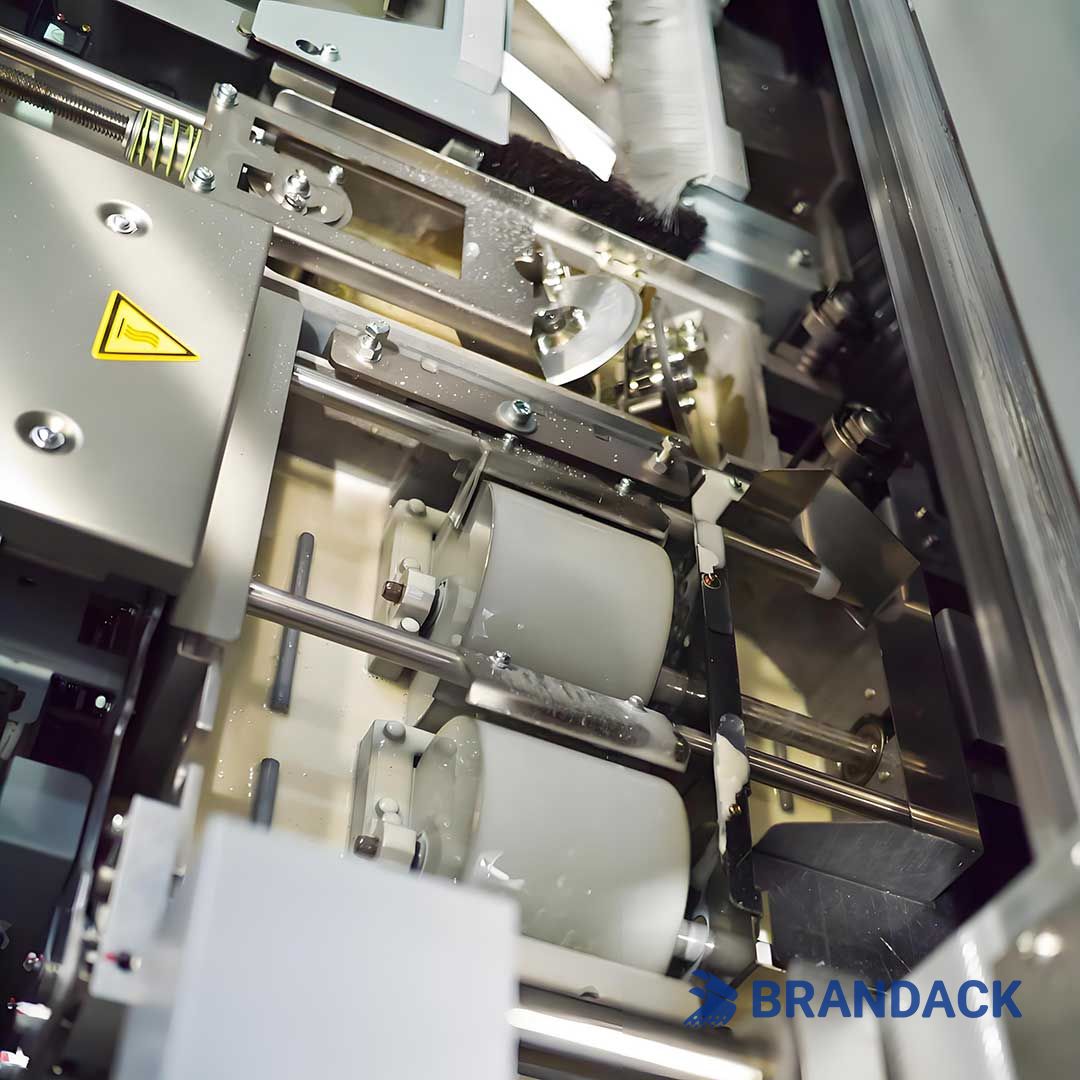

✅ Letterpress Machines: Manual tabletop presses (for small jobs) or automated cylinder presses (for high-volume packaging). Key features to prioritize: adjustable pressure controls, consistent ink distribution, and alignment guides for multi-color jobs.

✅ Inking Systems: Roller-based systems that evenly coat plates - avoid over-inking (causes smudges) or under-inking (leaves faint text).

Custom Relief Printing Process: From Concept to Finished Product

Our tailored workflow ensures your project aligns with brand goals. Here’s how we deliver custom letterpress packaging:

Step 1: Design Consultation & Prep

Collaborate with your team to finalize artwork: Ensure text is at least 8pt (smaller text may blur under pressure) and avoid fine lines (under 0.5pt). Add a 1/8" bleed to prevent white edges on finished packaging.

Convert designs to vector files (AI, EPS) for crisp plate creation - raster images (JPG, PNG) may lose detail.

Step 2: Plate Making

Create raised plates from your design: For multi-color jobs, we produce separate plates for each ink color (e.g., one for brand red, one for gold accents).

Test plates on scrap paper to verify detail and alignment before full production.

Step 3: Press Setup & Test Runs

Mount plates on the press cylinder and adjust pressure (too much = paper tearing; too little = uneven texture).

Run 5-10 test pieces to check ink coverage, color accuracy, and texture depth. Adjust as needed (e.g., add more ink for bolder color, reduce pressure for delicate paper).

Step 4: Batch Printing

Print in consistent batches (50-100 pieces at a time) to maintain quality. For large orders, pause periodically to clean plates and re-calibrate pressure.

Step 5: Post-Press Finishing

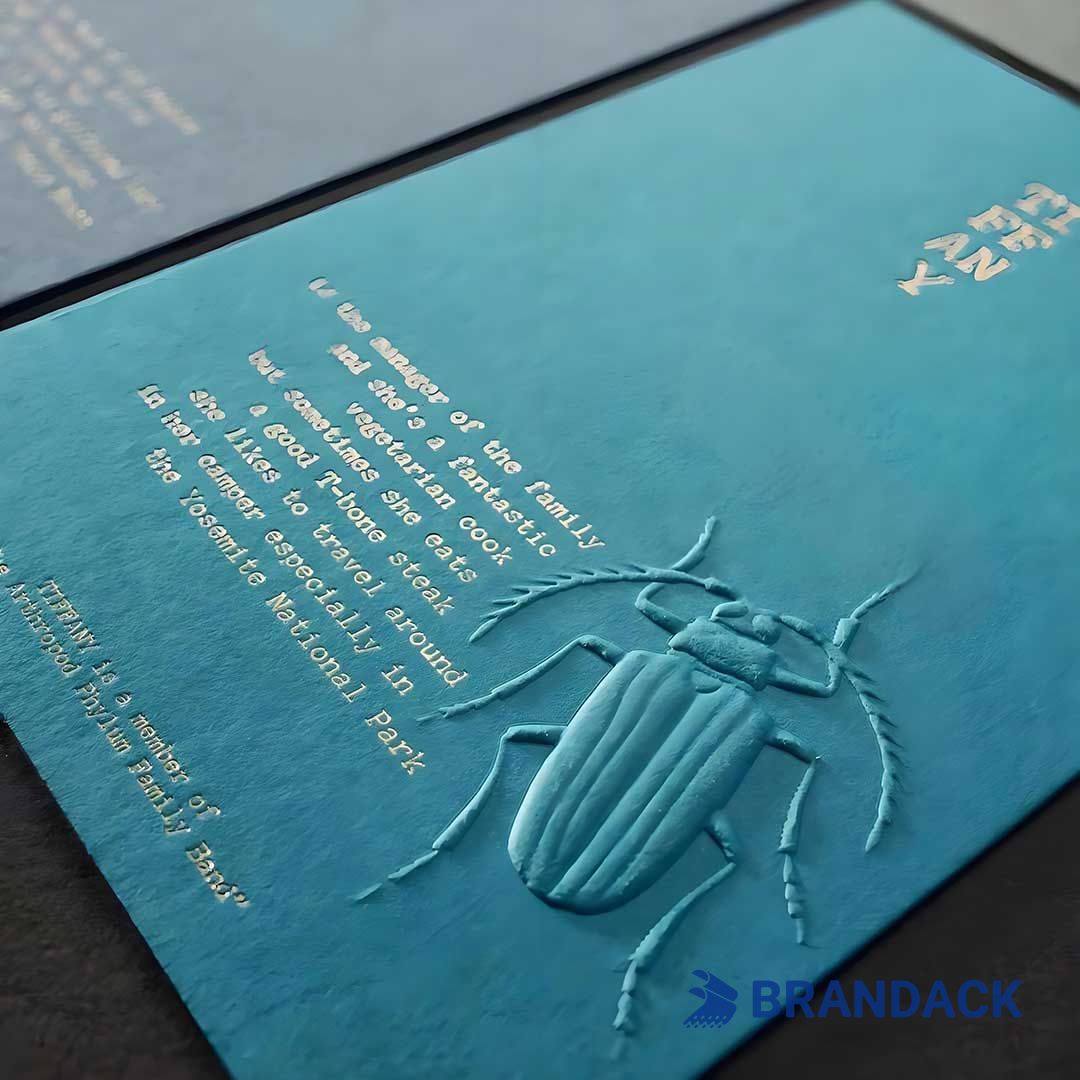

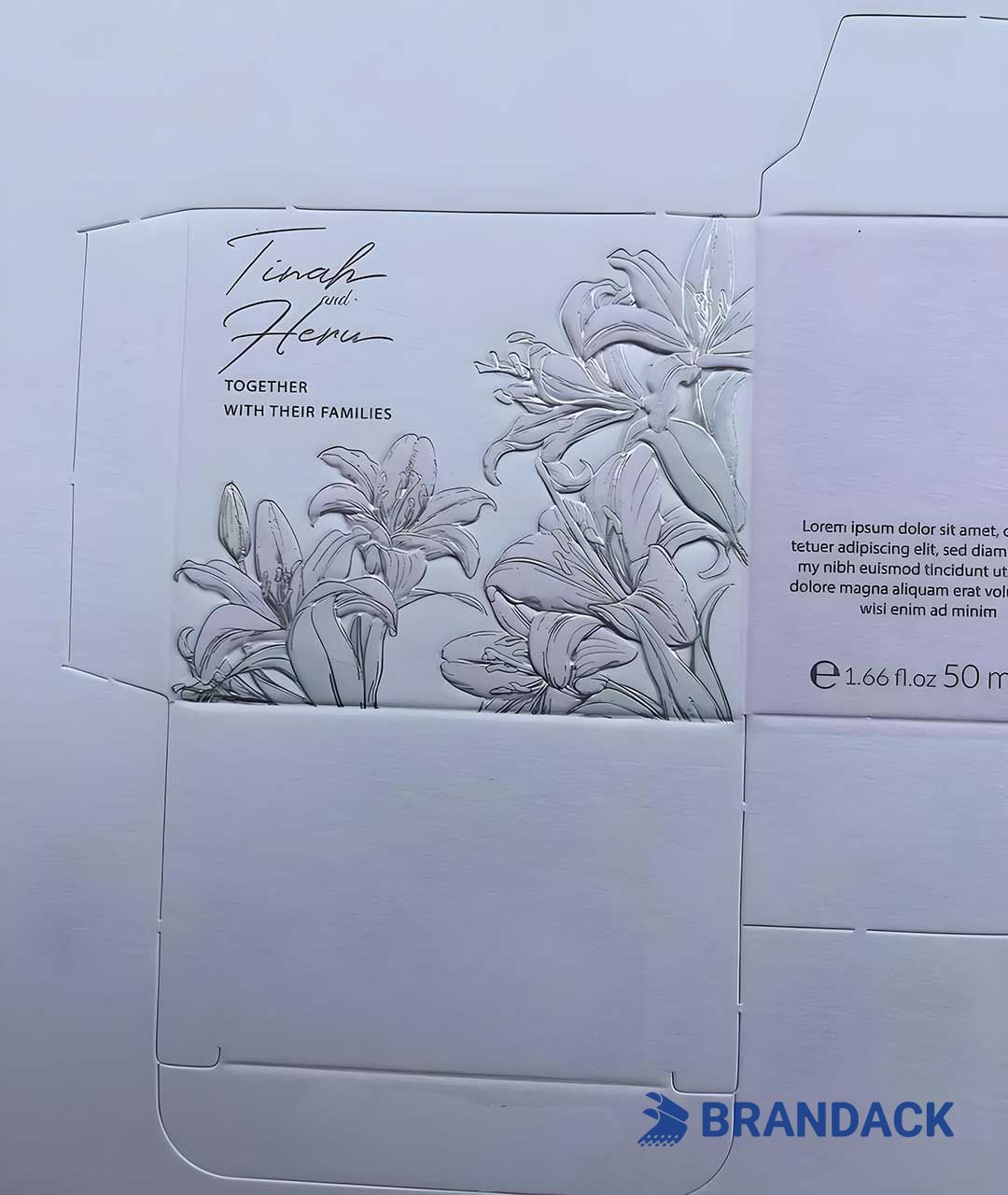

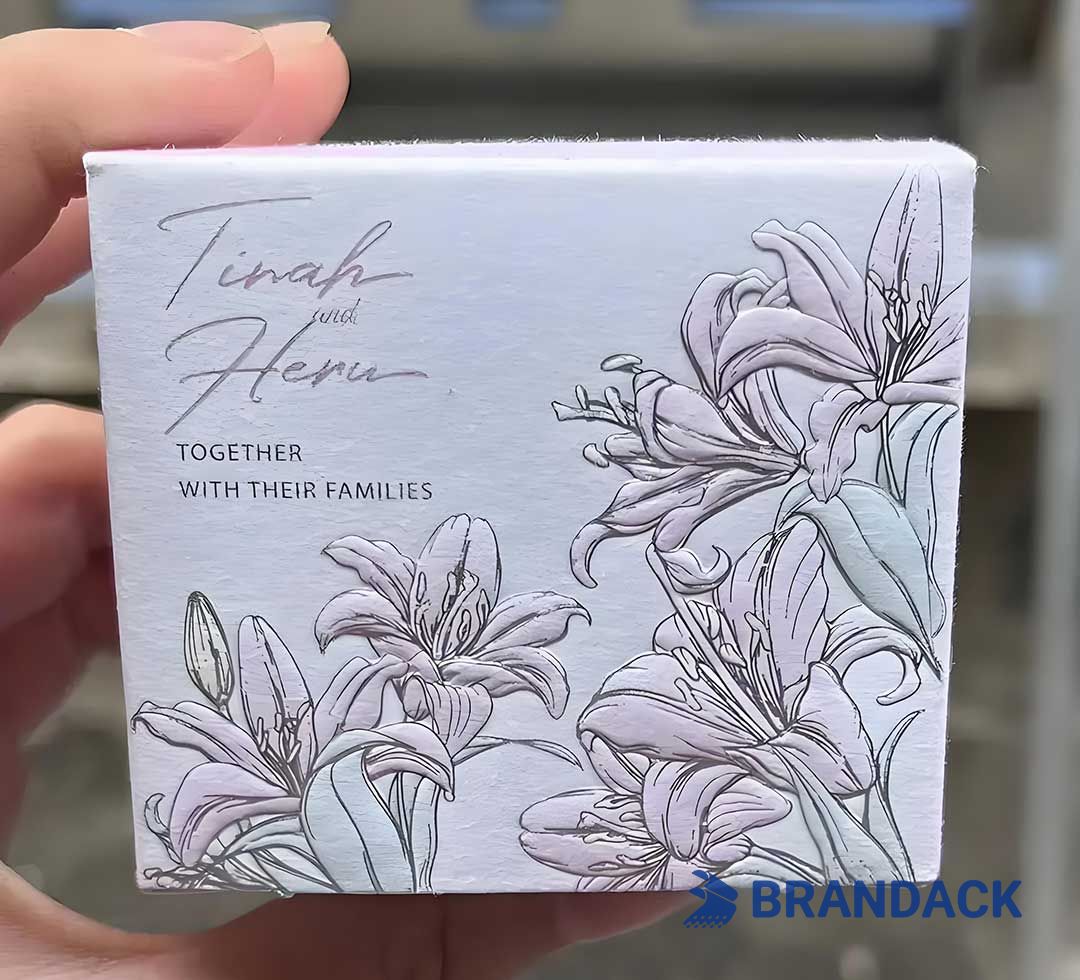

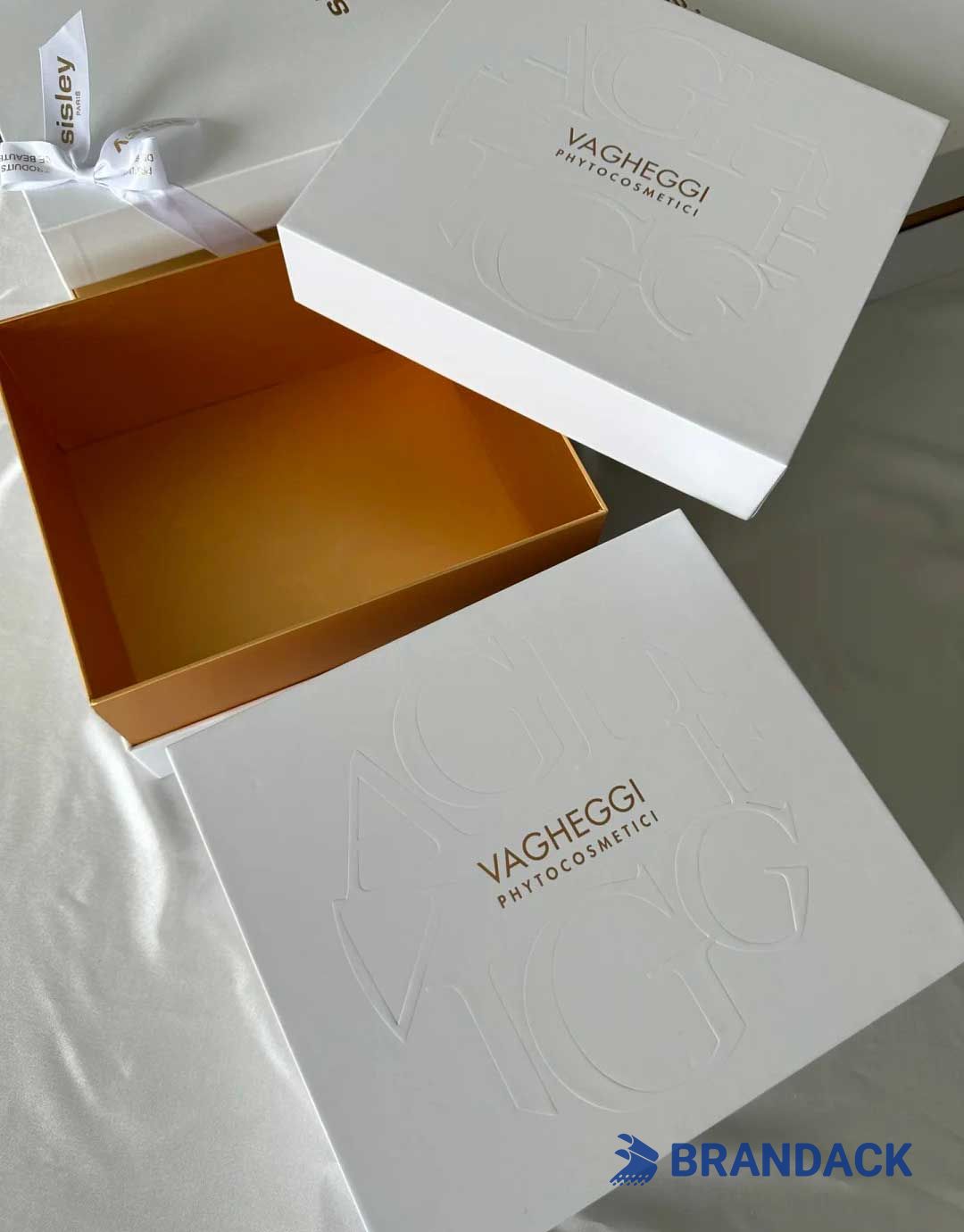

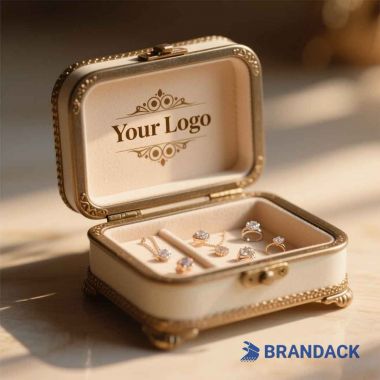

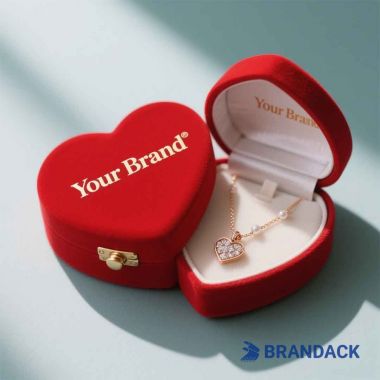

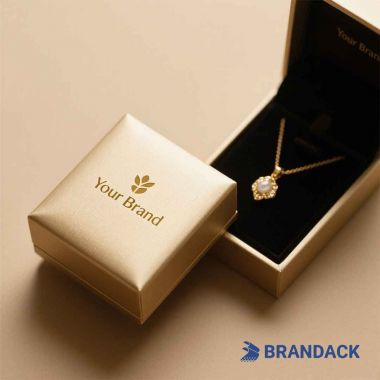

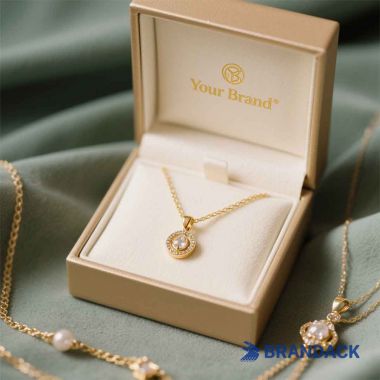

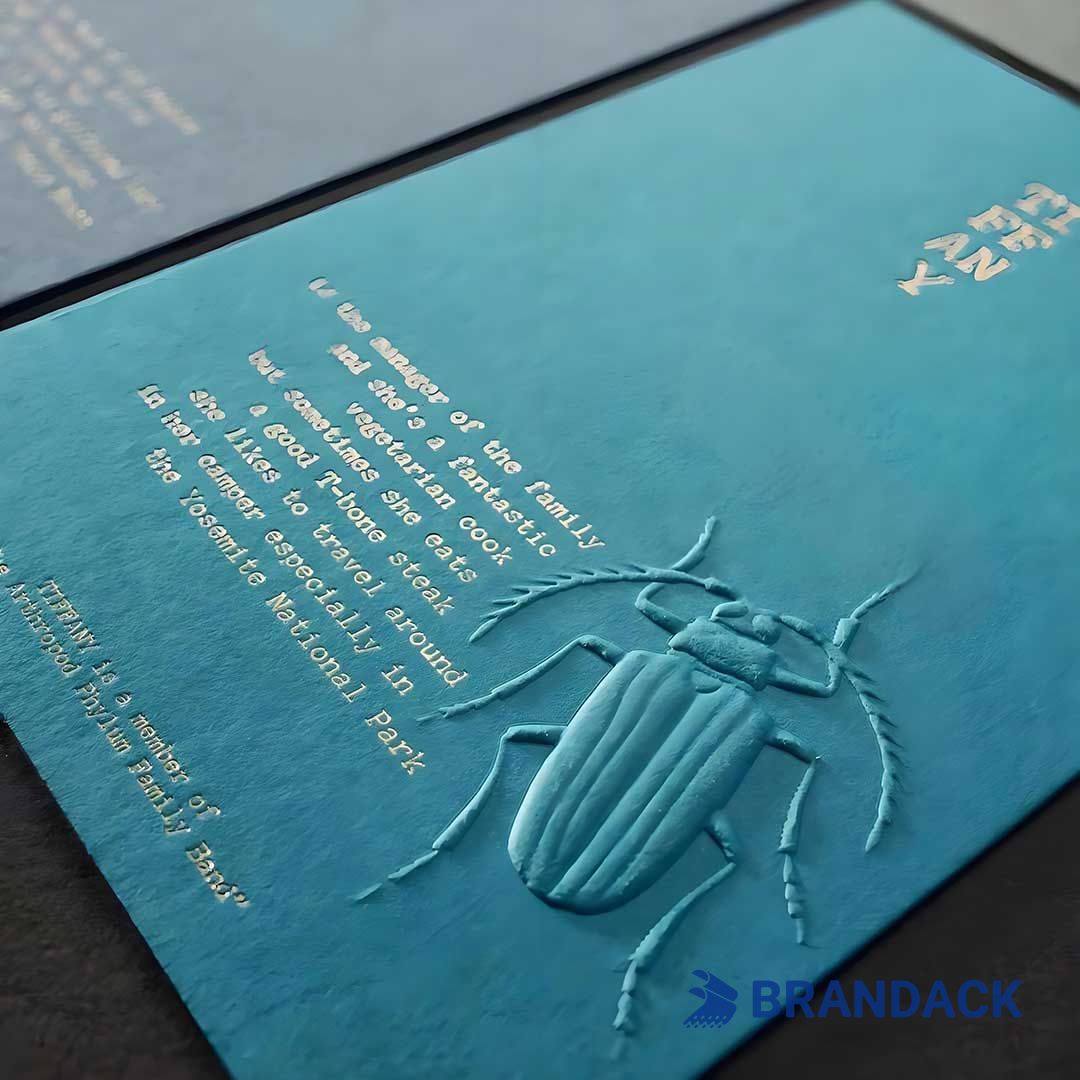

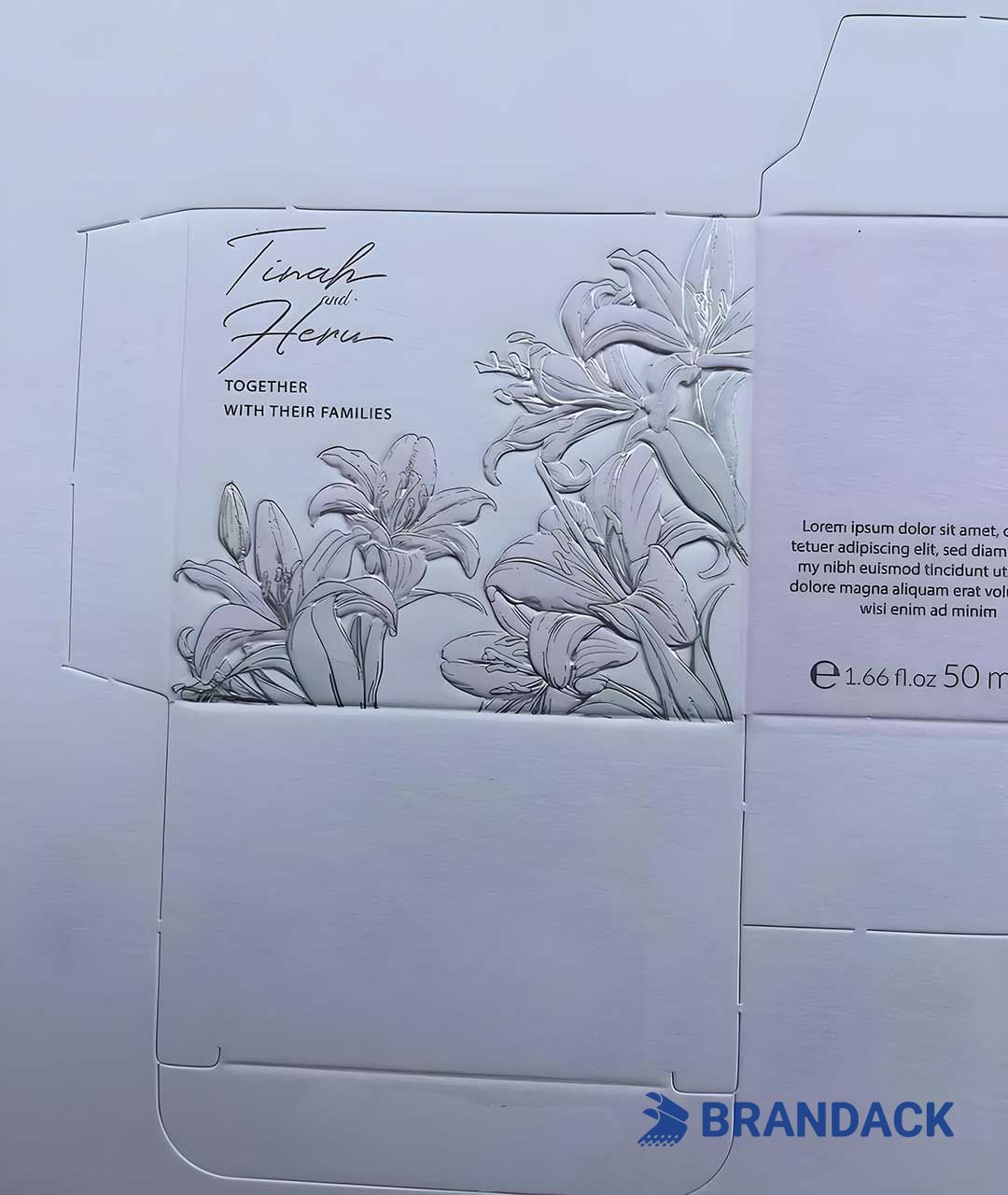

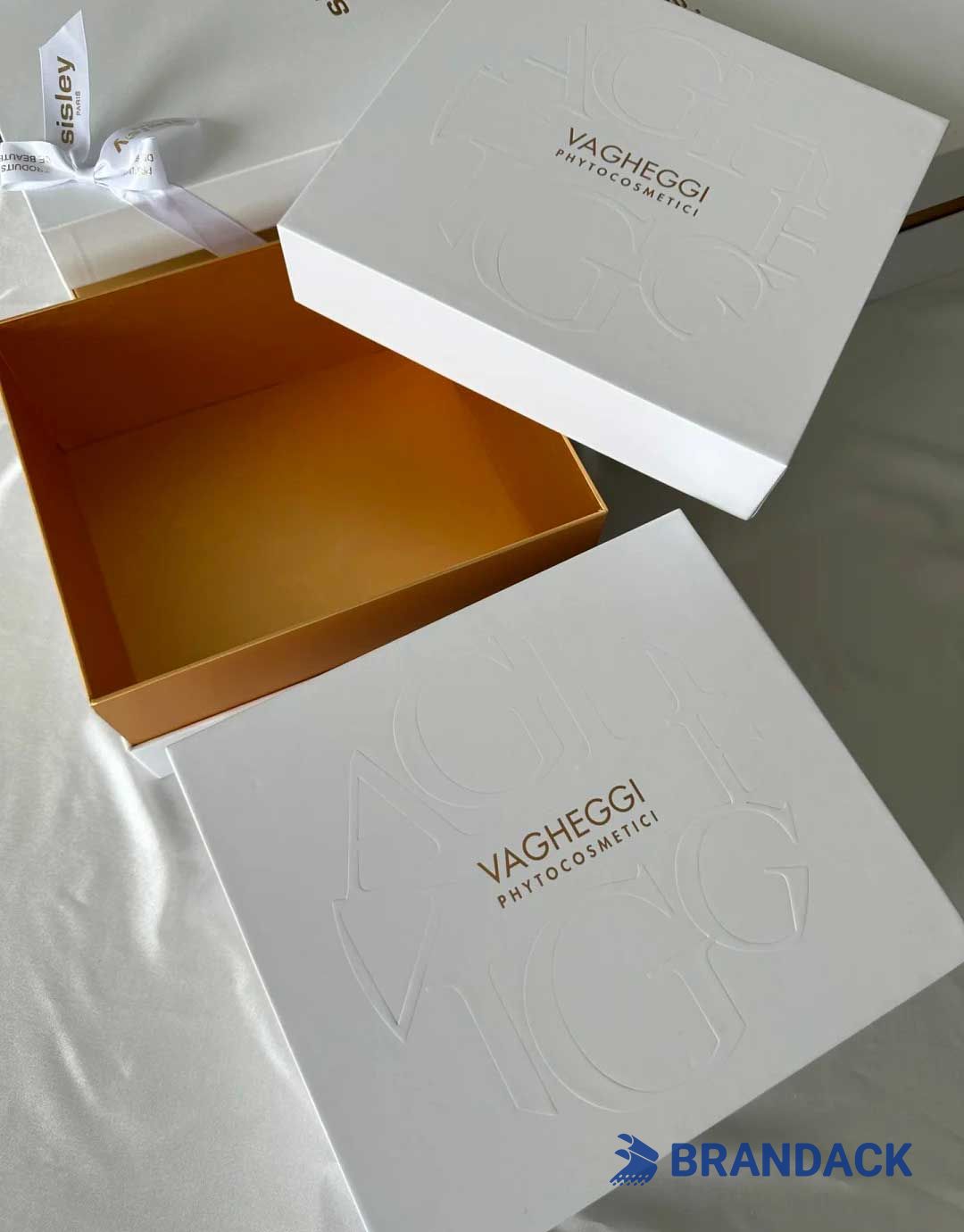

Add complementary packaging touches: Die-cutting (for custom shapes like gift boxes), foil stamping (for metallic accents), or embossing (to enhance texture).

Cure printed pieces in a low-humidity area (60-70°F) for 24-48 hours to prevent ink smudging.

Troubleshooting Common Challenges:

✅ Shallow Impression: Adjusting pressure, material density, and plate depth ensures a deep, clear deboss.

✅ Ink Bleeding: Optimal ink viscosity and paper choice prevent spread and maintain sharp edges.

✅ Registration Issues: Modern press controls and hand-fed precision ensure perfect alignment.

Why Choose Our Letterpress Services?

At BRANDACK, we blend traditional craftsmanship with modern efficiency. Our team has 10+ years of experience creating custom letterpress packaging for brands in food, beauty, and luxury goods. We offer:

P Custom material sourcing (eco-friendly papers, FDA-approved inks).

P Dedicated project managers to guide you from design to delivery.

P Quick turnaround (7-10 days for small batches; 2-3 weeks for large orders).

Ready to bring your brand’s vision to life?

Contact our team by email to schedule a consultation, or browse our case studies to see how we’ve solved letterpress challenges for clients like you.