Lithographic printing - often shortened to “litho” - is a cornerstone of modern packaging and commercial printing, celebrated for its ability to produce sharp, color-accurate results across diverse substrates. From food packaging boxes to luxury cosmetic containers and promotional brochures, litho remains a top choice for businesses prioritizing quality and scalability. This guide breaks down its core principles, step-by-step workflow, and critical quality assurance (QA) practices to help you make informed decisions for your printing projects.

Fundamentals of Lithographic Printing

At its heart, litho relies on a timeless scientific principle: oil and water do not mix. Unlike relief printing (where ink sits on raised surfaces) or gravure (where ink fills recessed grooves), litho uses a flat printing plate - most commonly aluminum - to create two distinct, invisible zones:

✅ Hydrophobic (oil-loving) zones: Treated to attract ink, these areas reproduce the design (text, logos, images).

✅ Hydrophilic (water-loving) zones: Repel ink, acting as the “negative” space of the design.

Key Fundamentals to Understand:

✅ Plate Technology: Modern litho plates use photopolymer or thermal coatings, enabling precise reproduction of fine details (e.g., 0.1mm text or gradient colors) critical for branding and packaging.

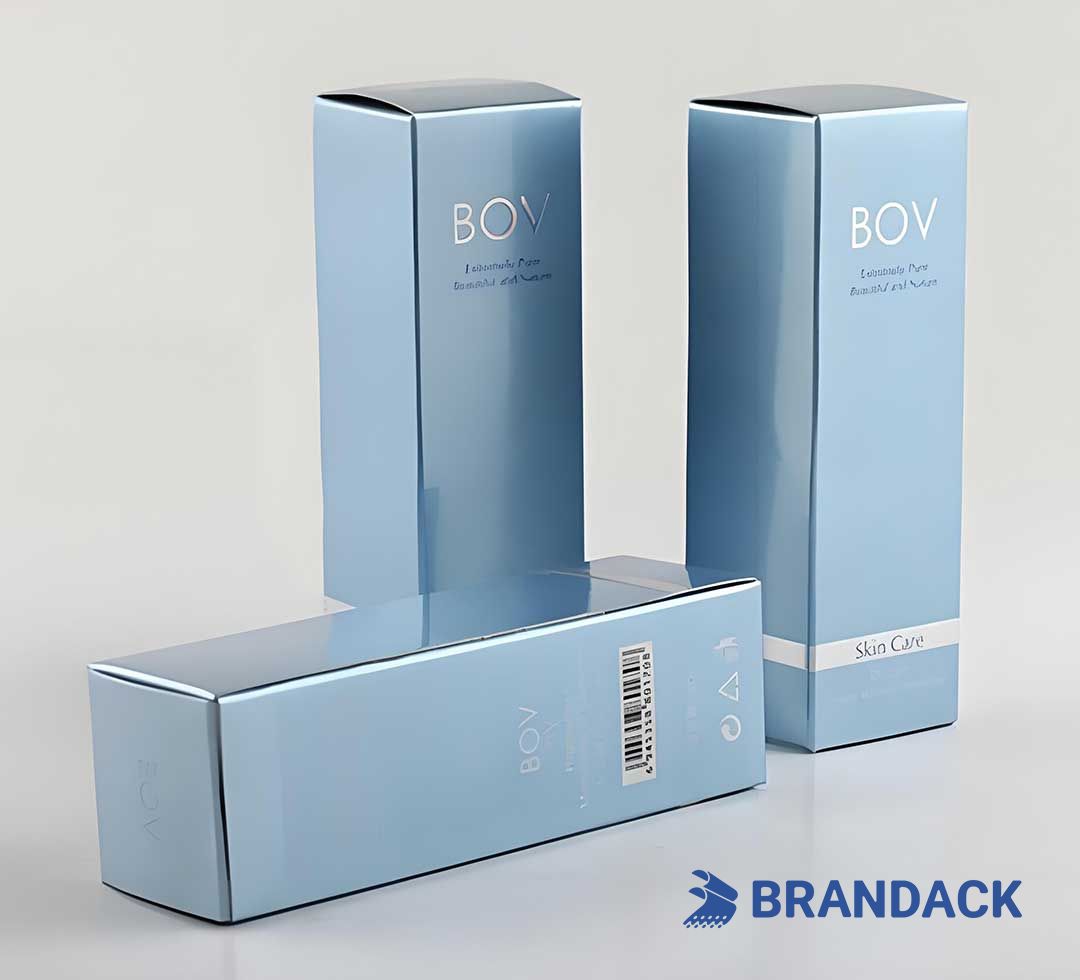

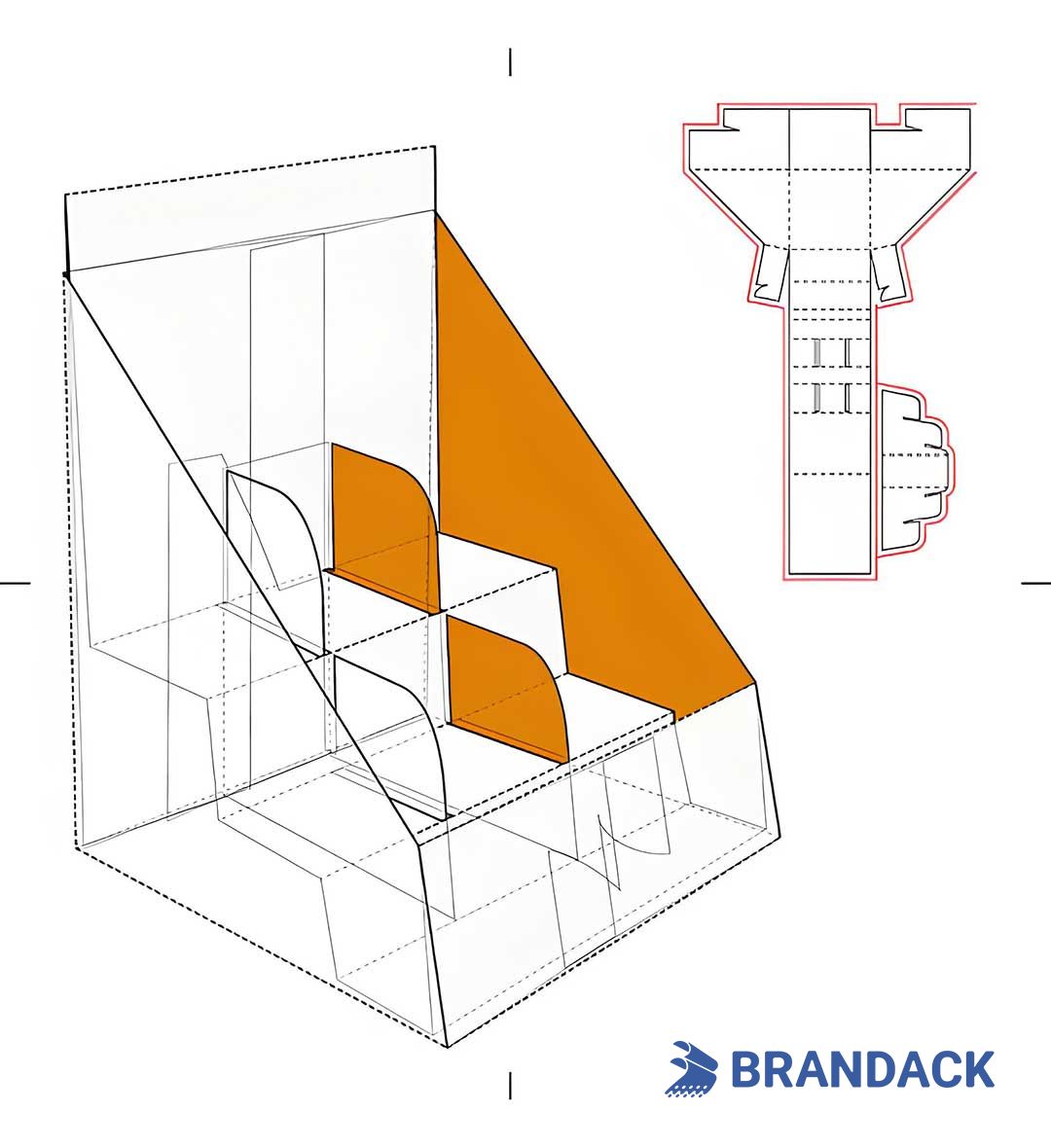

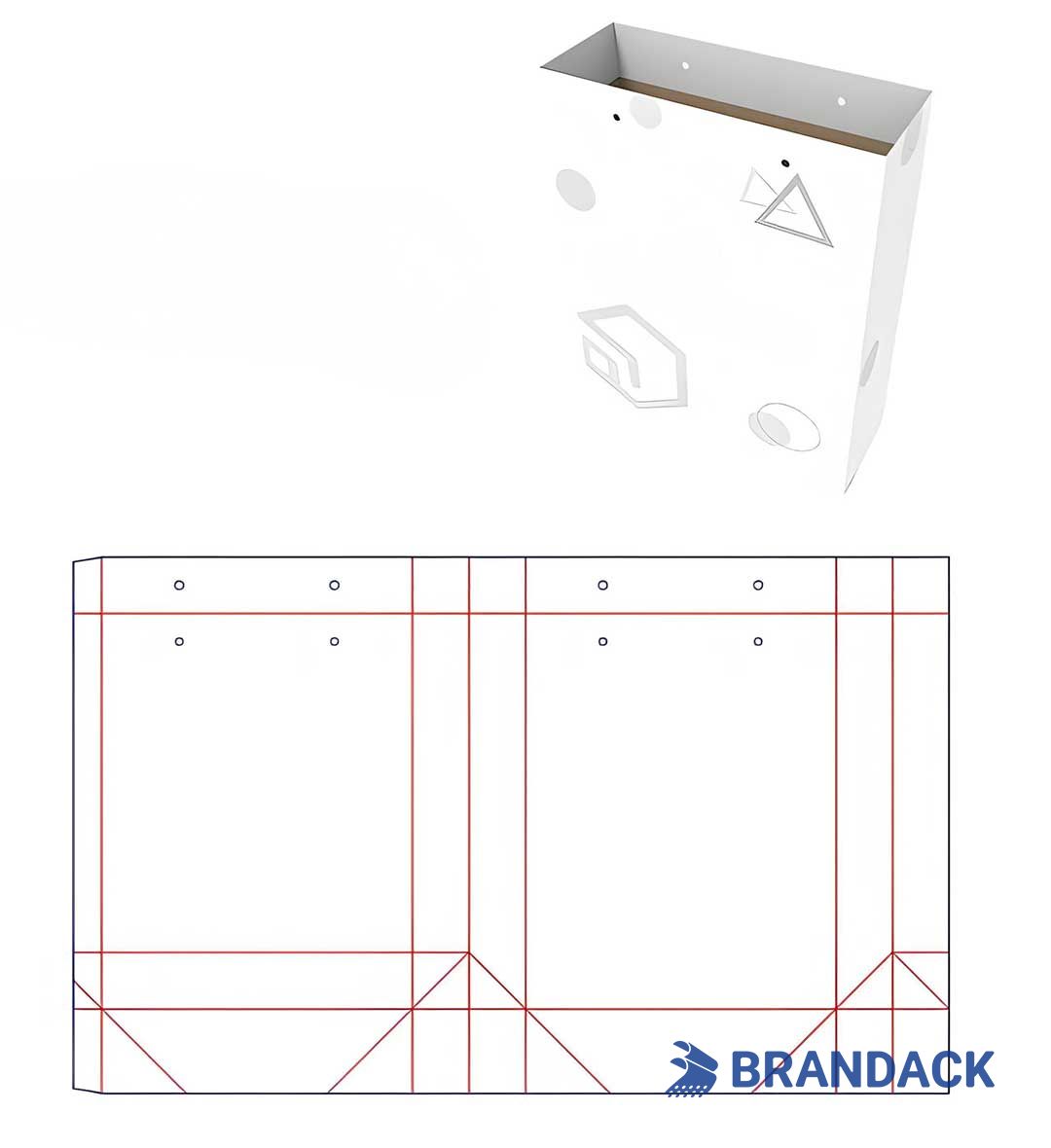

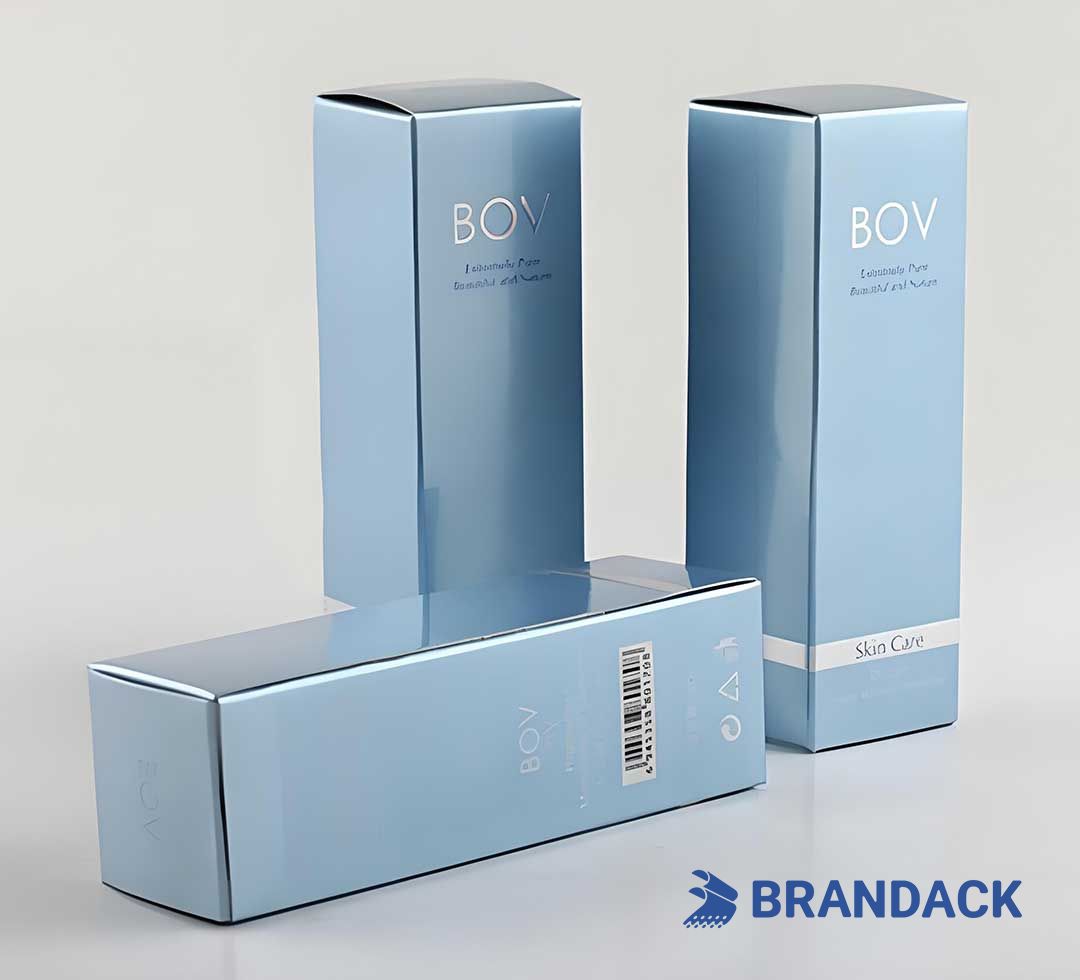

✅ Substrate Versatility: Litho excels on materials like coated/uncoated paper, cardboard, plastic films (PET, PP), and even metal sheets - making it ideal for rigid packaging, flexible pouches, and retail displays.

✅ Color Capability: It supports full-color printing via CMYK (Cyan, Magenta, Yellow, Key/Black) or custom spot colors (for brand-specific hues, e.g., Pantone matches), ensuring consistency with brand guidelines.

✅ Efficiency: Litho shines in high-volume runs (1,000+ units) due to fast setup times and consistent output, balancing premium quality with cost-effectiveness for commercial needs.

Step-by-Step Lithographic Printing Process

Our streamlined workflow ensures accuracy and speed, from design to finished product. Here’s how it works:

Step 1: Design & Prepress Preparation

The prepress stage prevents costly errors by refining the design file:

File Checks: Our team verifies format (PDF/X-1a recommended), color mode (CMYK - not RGB, for accurate reproduction), resolution (300 DPI minimum for sharpness), and bleed (3mm extra to avoid white edges after trimming).

Client Proofing: We share a digital soft proof (and optional physical hard proof) for approval, ensuring the design matches your vision before production.

Step 2: Plate Making

Using a computer-to-plate (CTP) system, the approved digital file is etched onto aluminum plates:

Laser Exposure: The CTP machine uses laser light to harden the plate’s ink-receptive coating, defining the design.

Development & Drying: Unhardened (hydrophilic) coating is washed away, and the plate is dried - creating the final ink/water-repellent zones. Each CMYK color requires a separate plate.

Step 3: Press Setup & Ink Mixing

Plates are mounted onto our precision presses (Heidelberg/Komori models), and technicians:

Ink Matching: Mix ink to match the approved proof, using spectrophotometers to ensure color accuracy (ΔE < 1, an industry benchmark for minimal variation).

Water & Pressure Adjustment: Calibrate the press’s water fountain (too much water blurs ink; too little causes smudges) and set cylinder pressure (to avoid substrate damage while ensuring even ink transfer).

Step 4: Printing Run

Make-Ready Tests: We print a small batch (“make-readies”) to confirm color, registration, and substrate compatibility. Only after client approval do we start full production.

Real-Time Monitoring: Operators check every 50–100 sheets for color consistency, registration (plate alignment), and defects (smudges, streaks). Automated cameras flag issues in high-volume runs.

Step 5: Post-Press Finishing

Printed sheets move to finishing to meet your packaging needs:

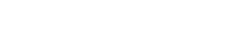

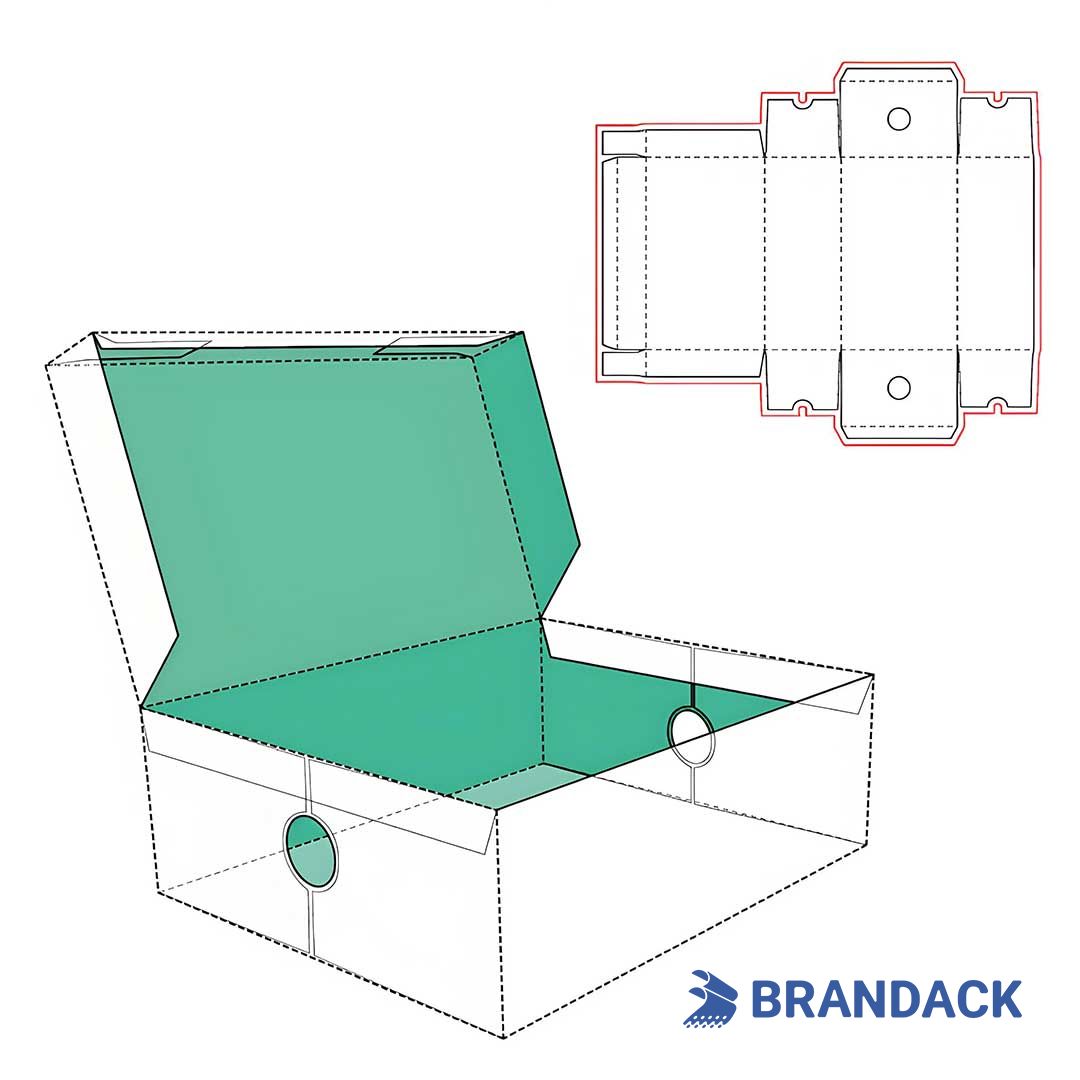

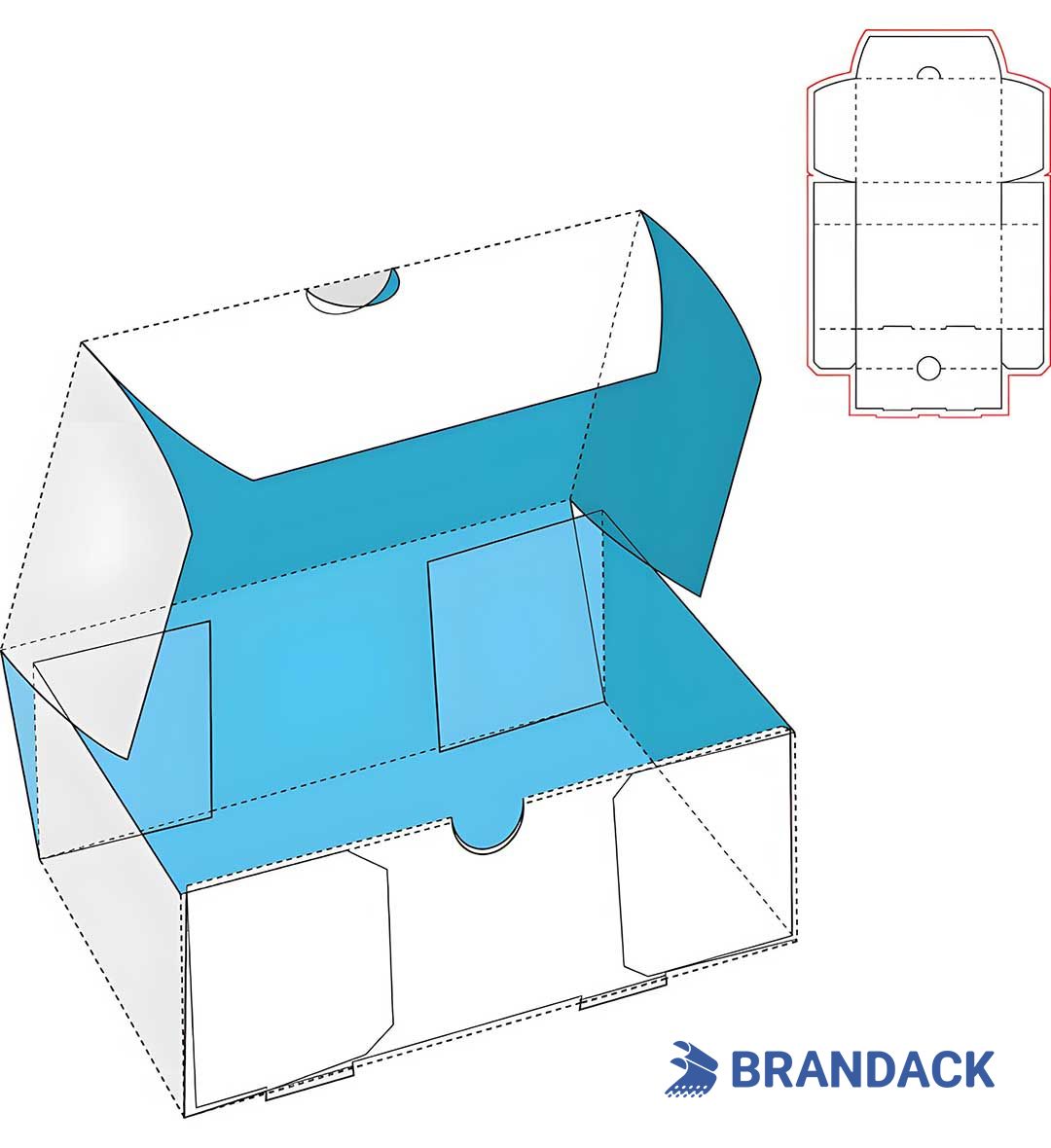

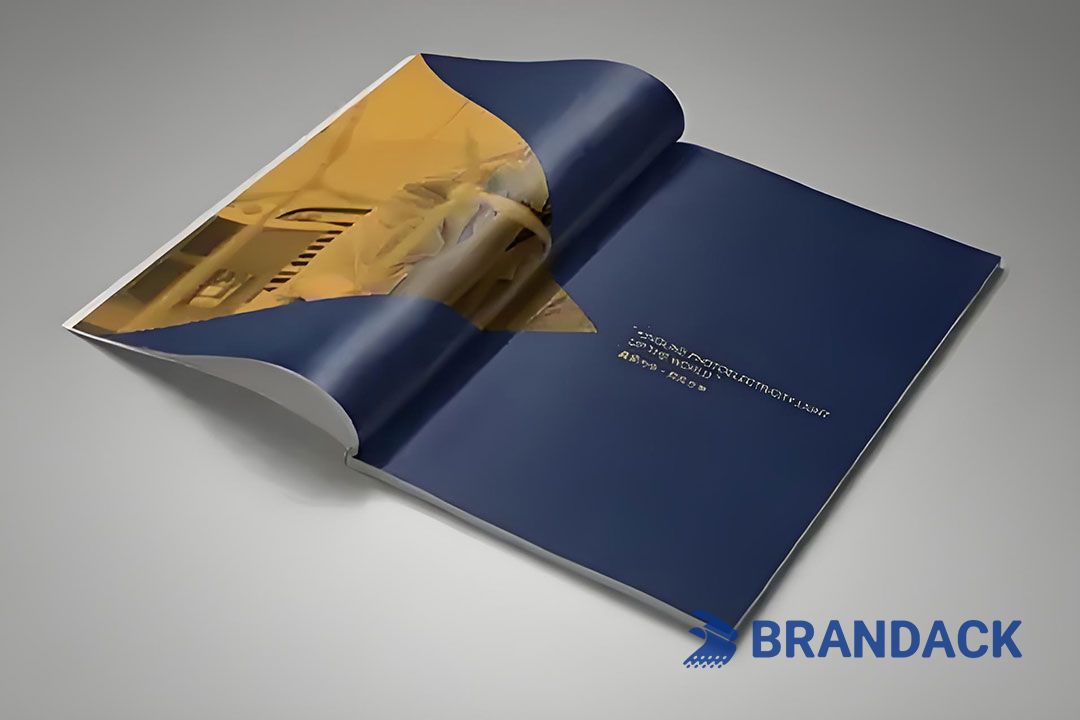

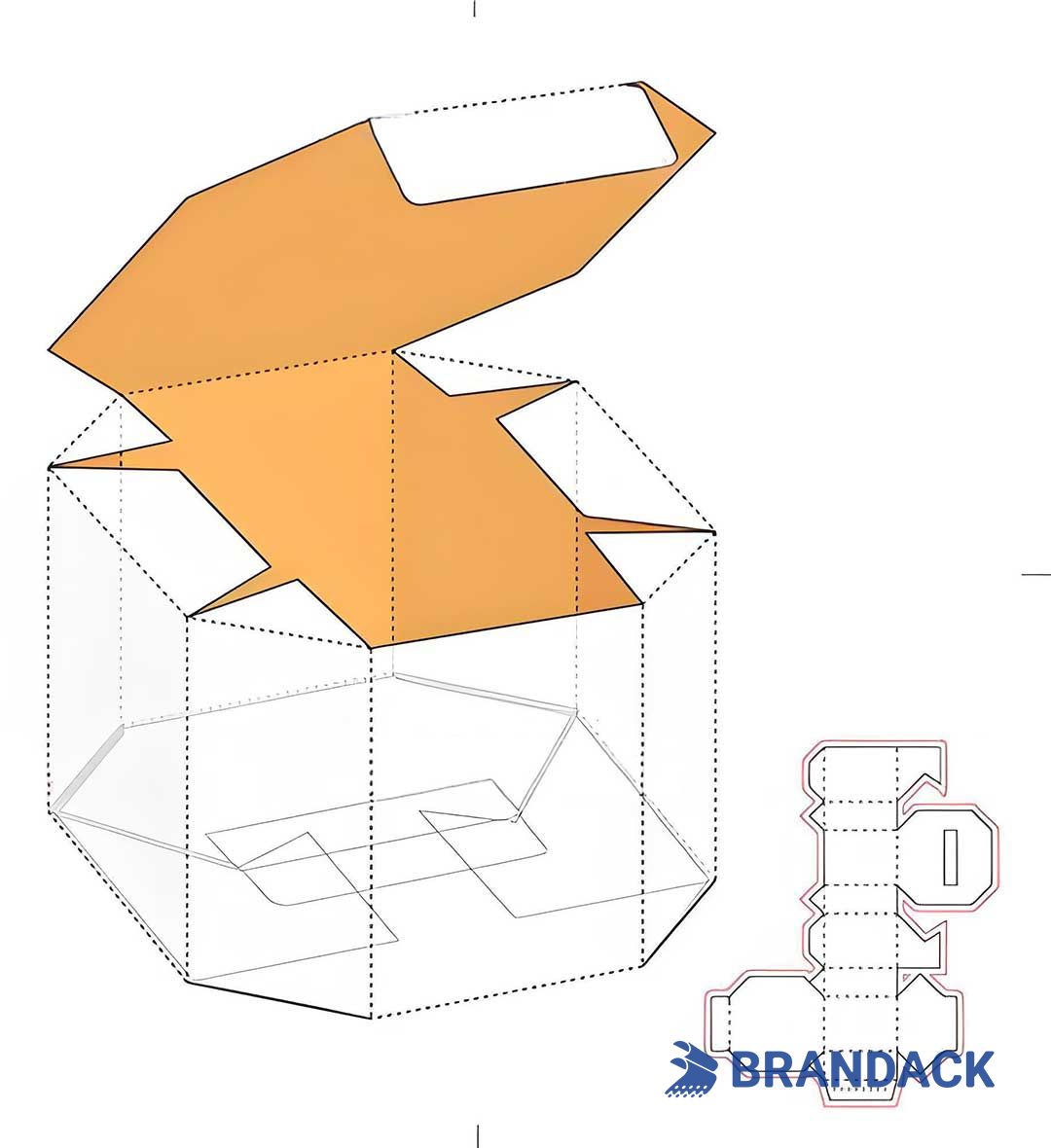

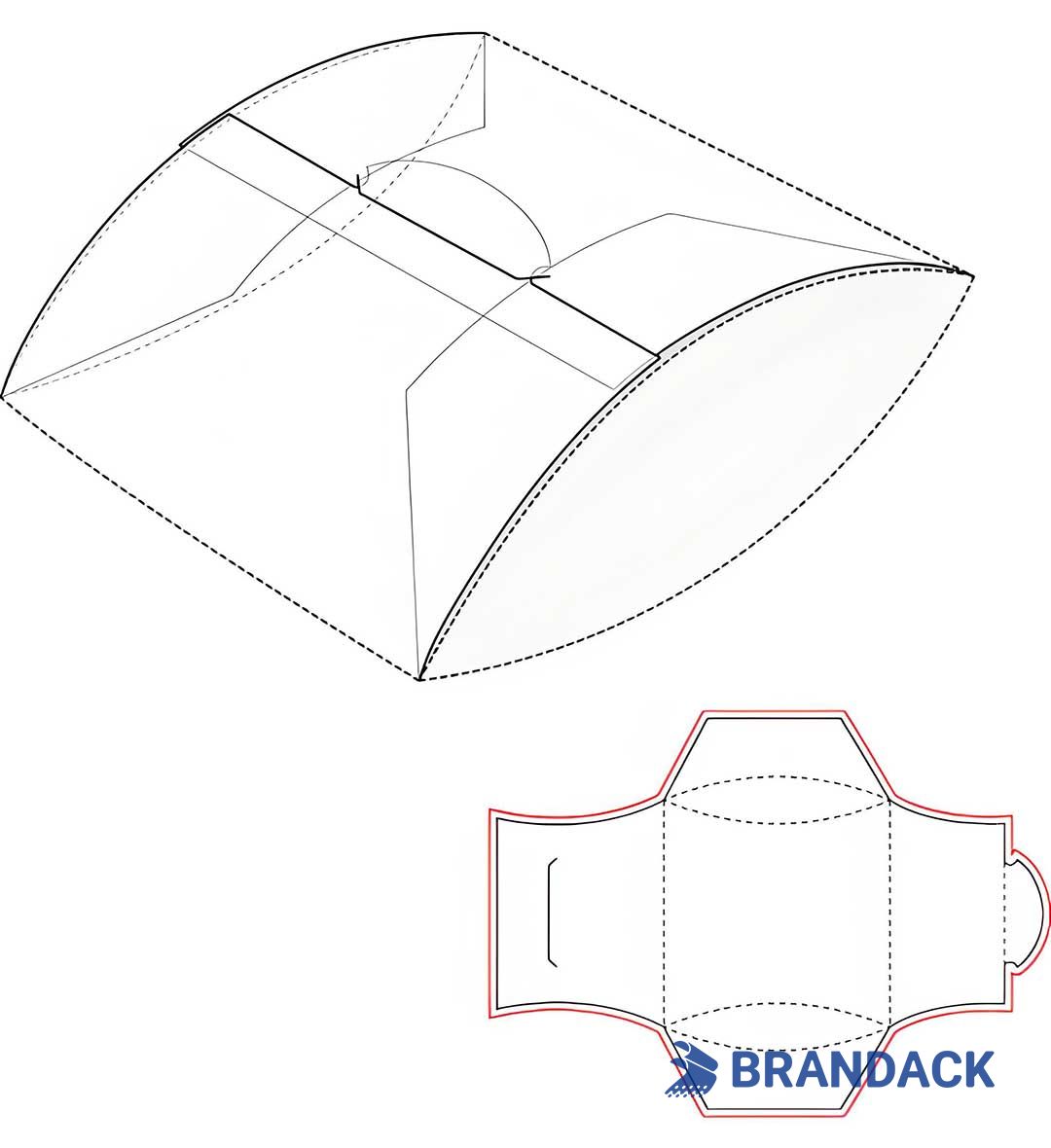

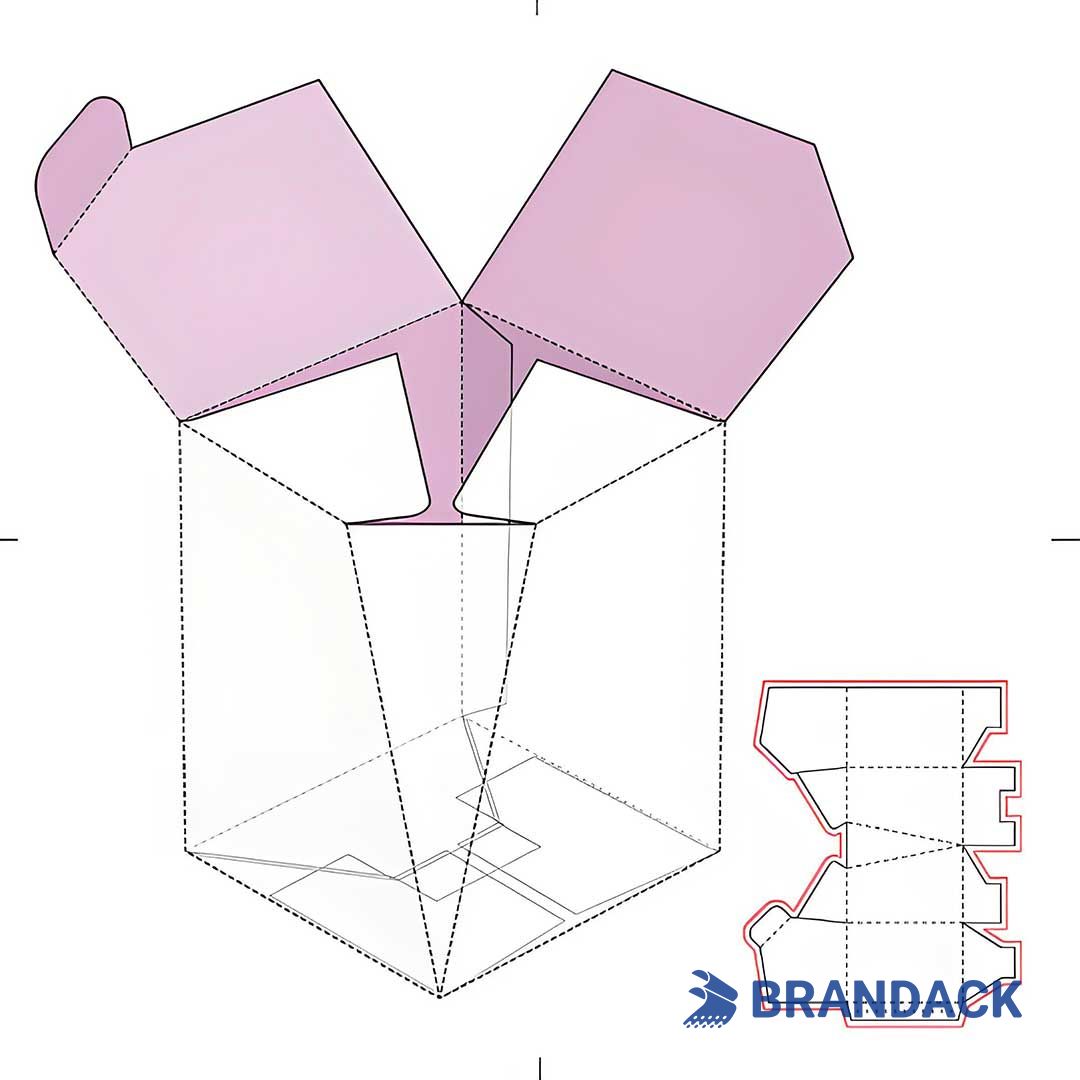

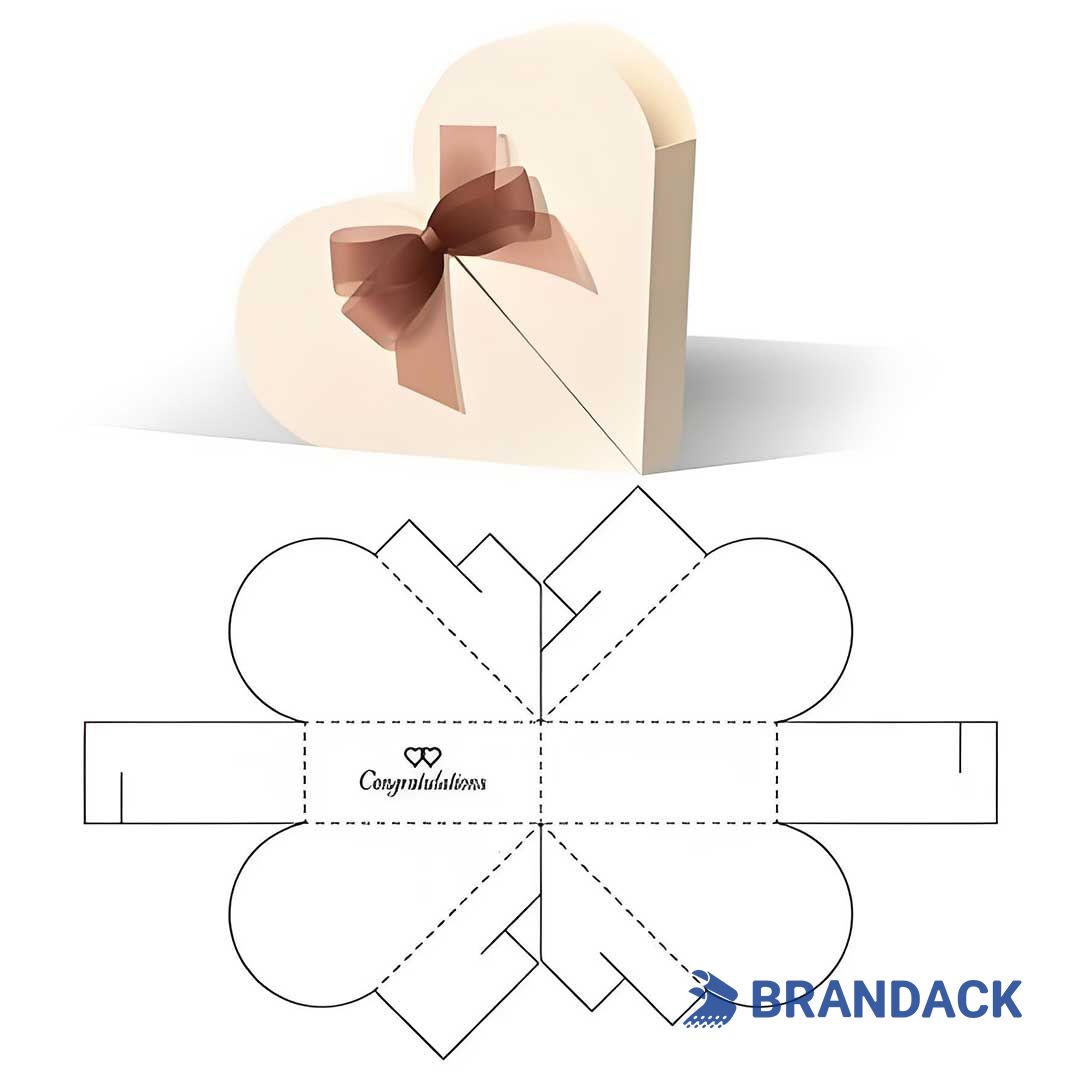

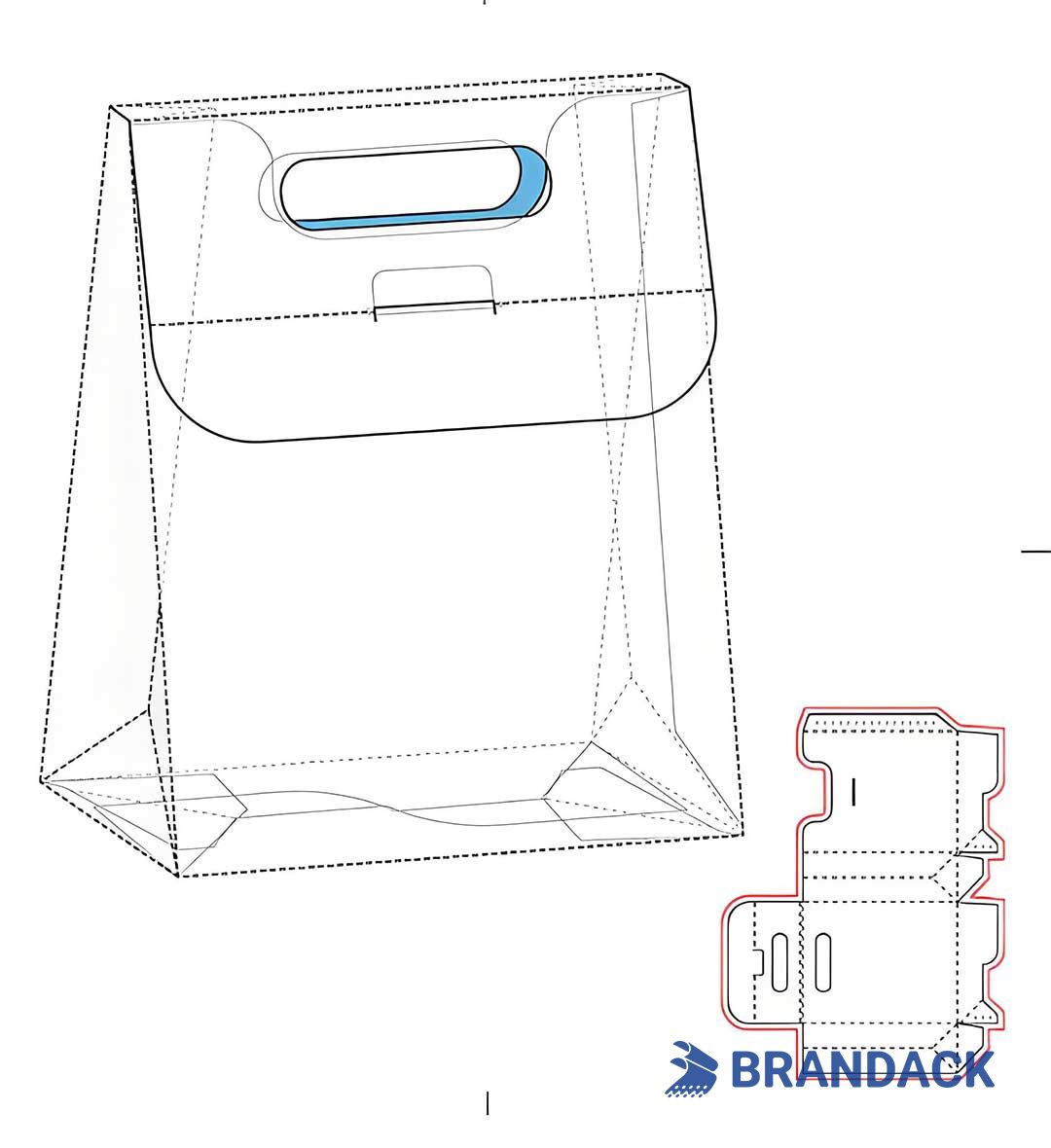

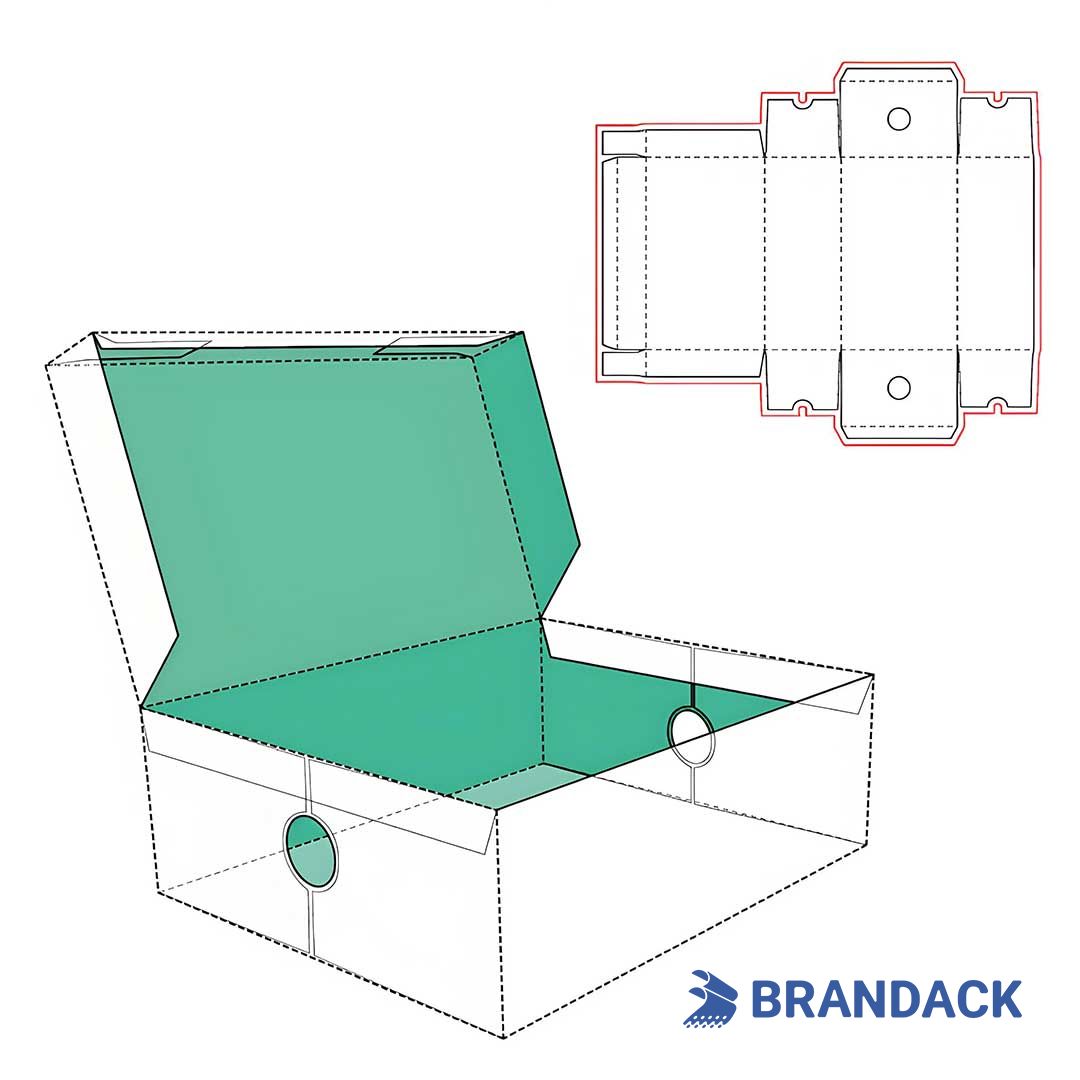

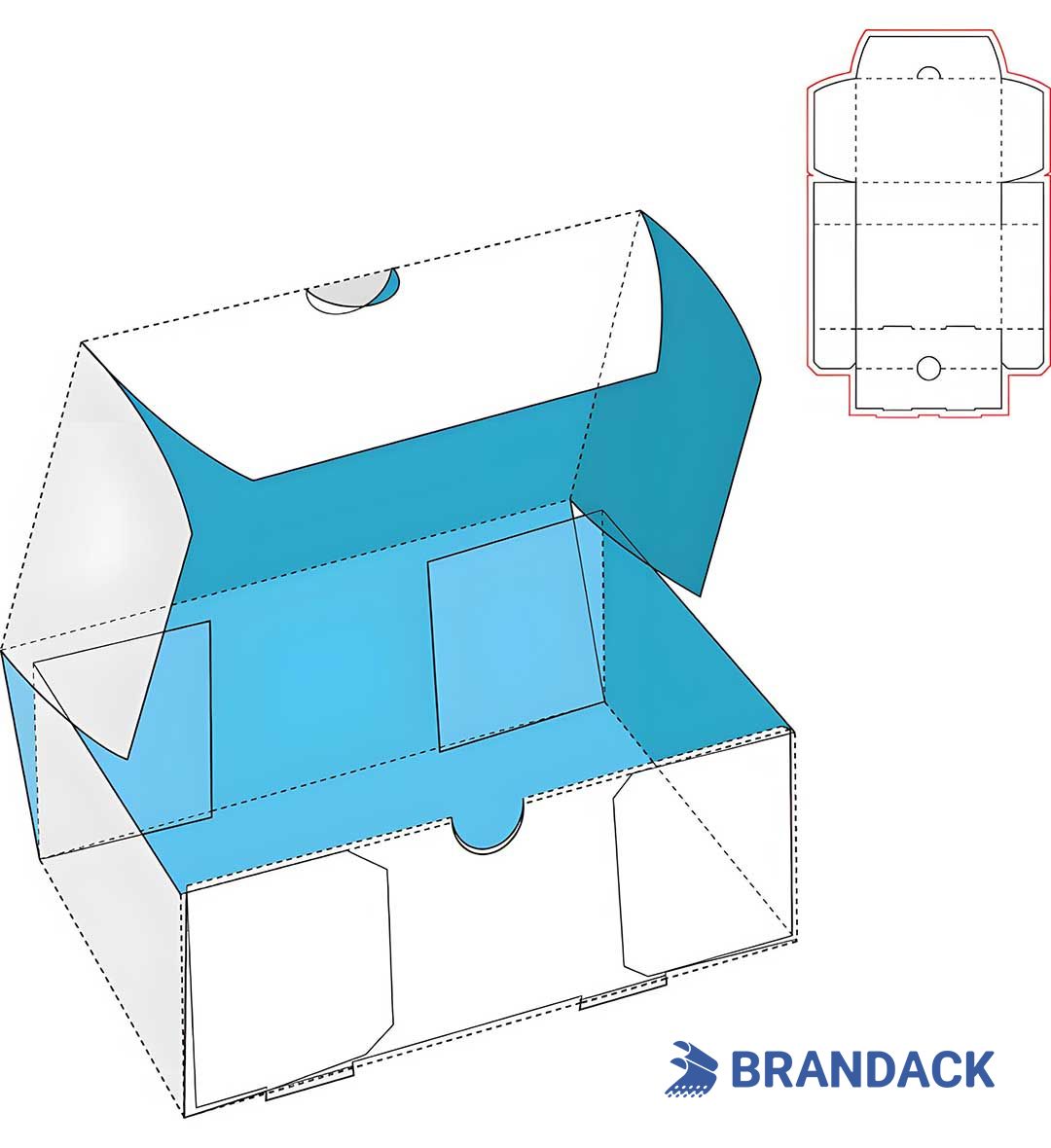

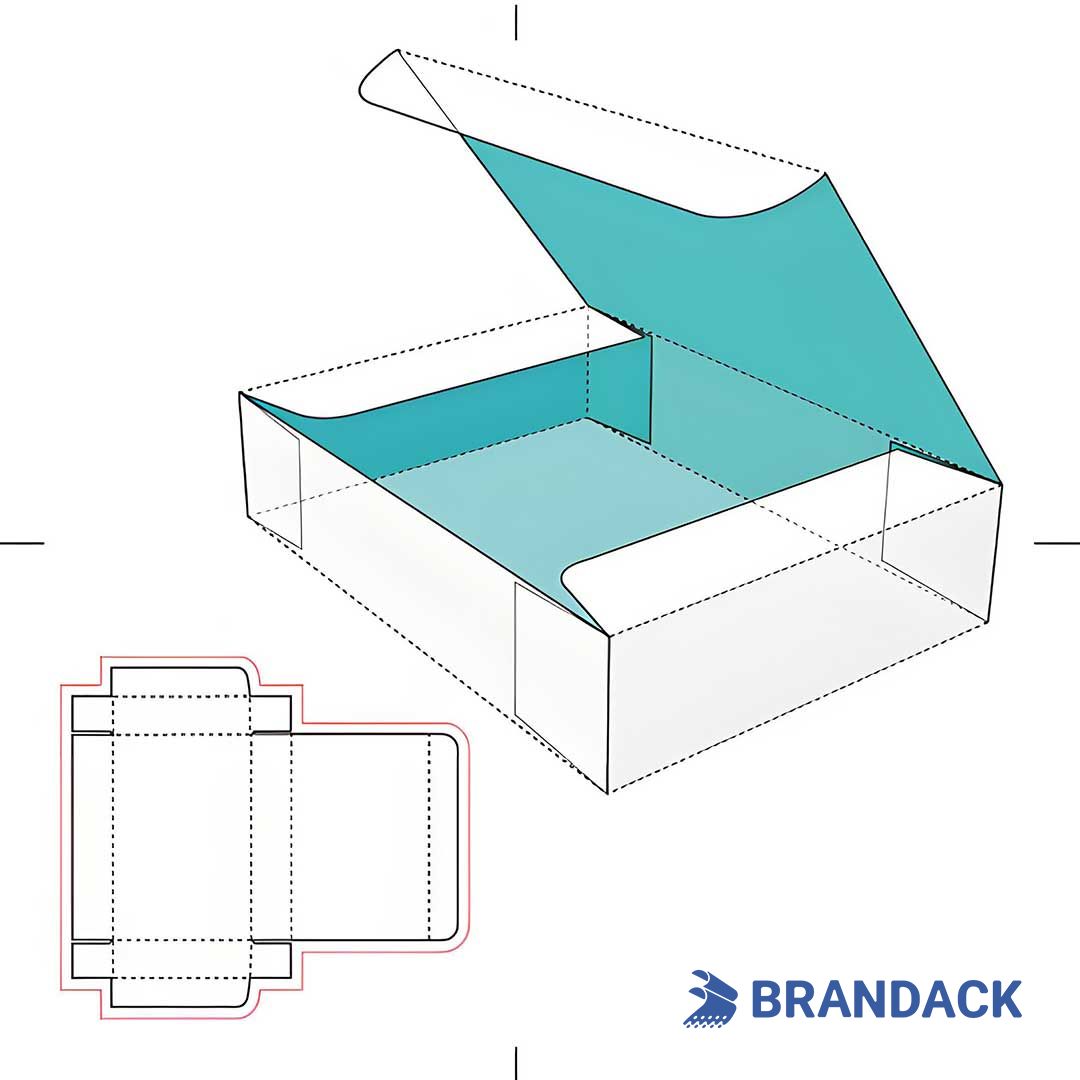

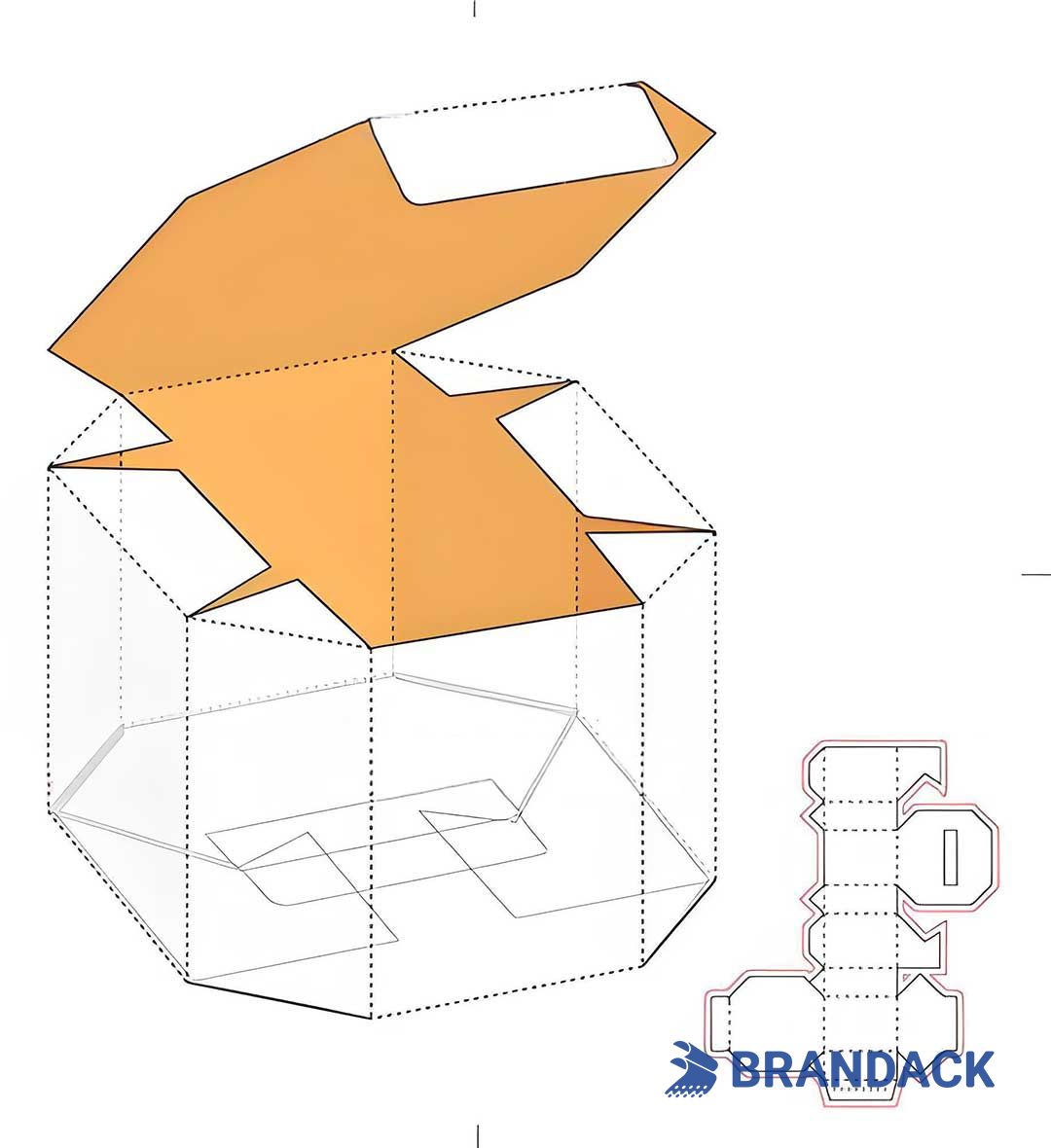

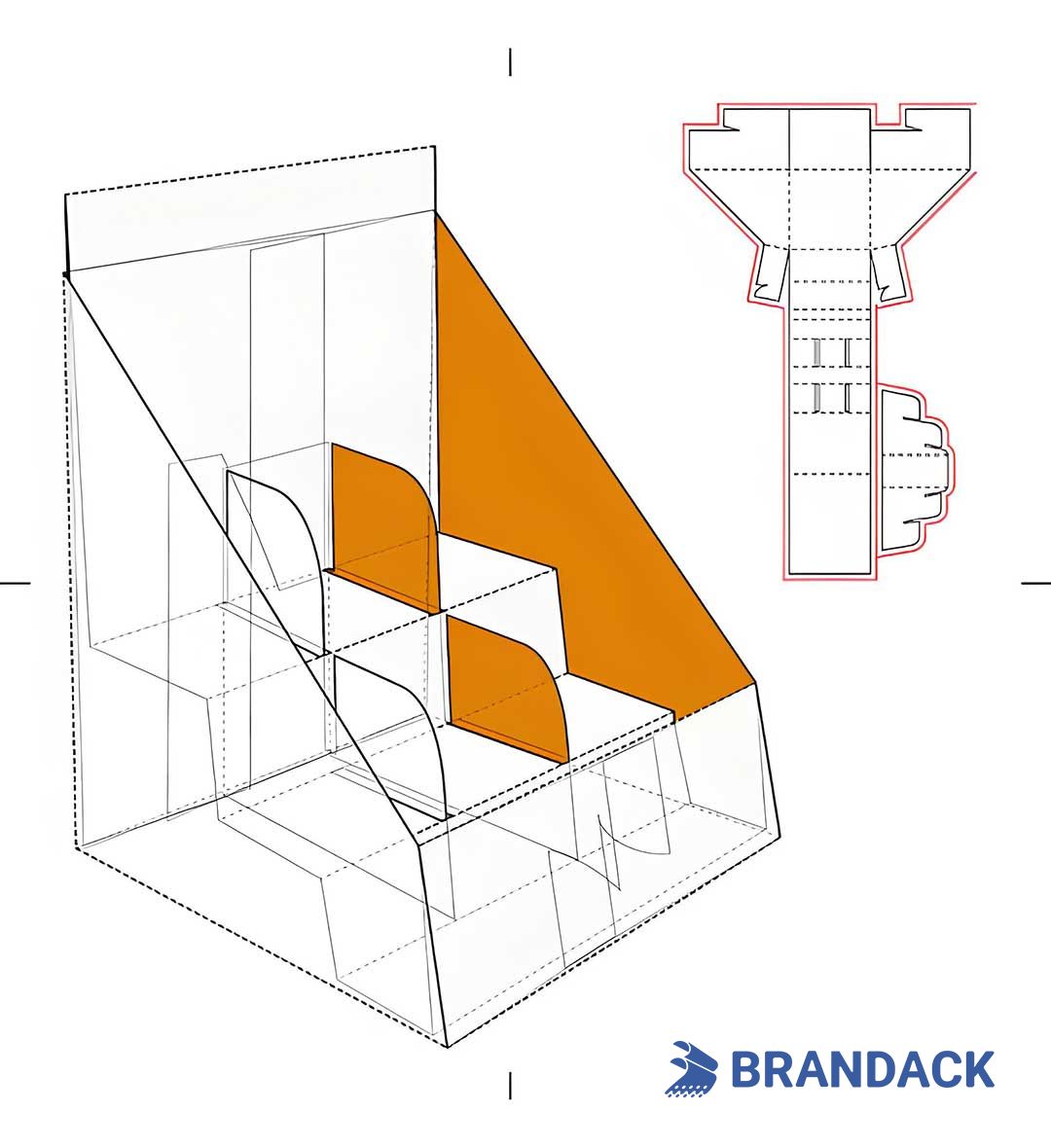

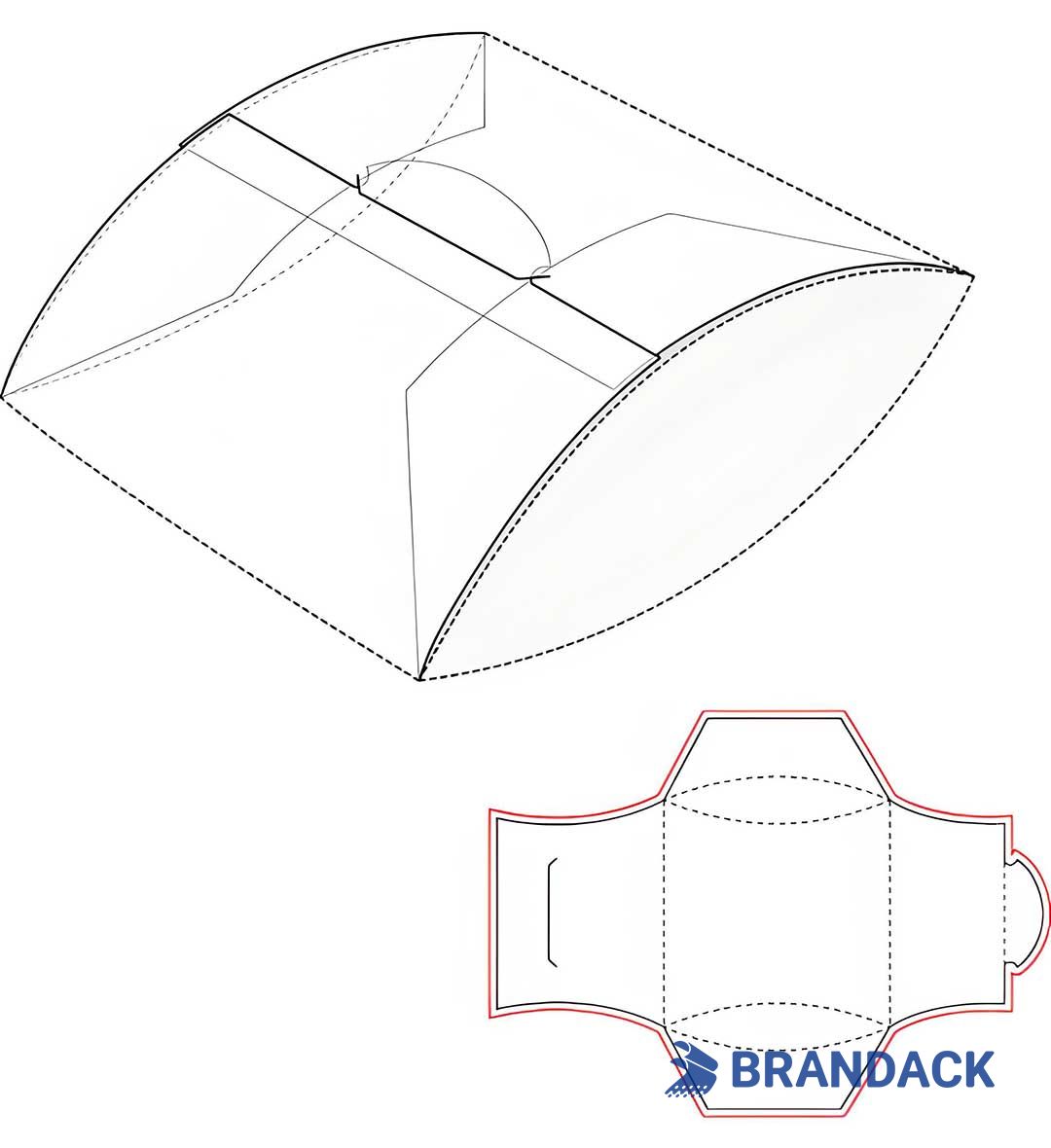

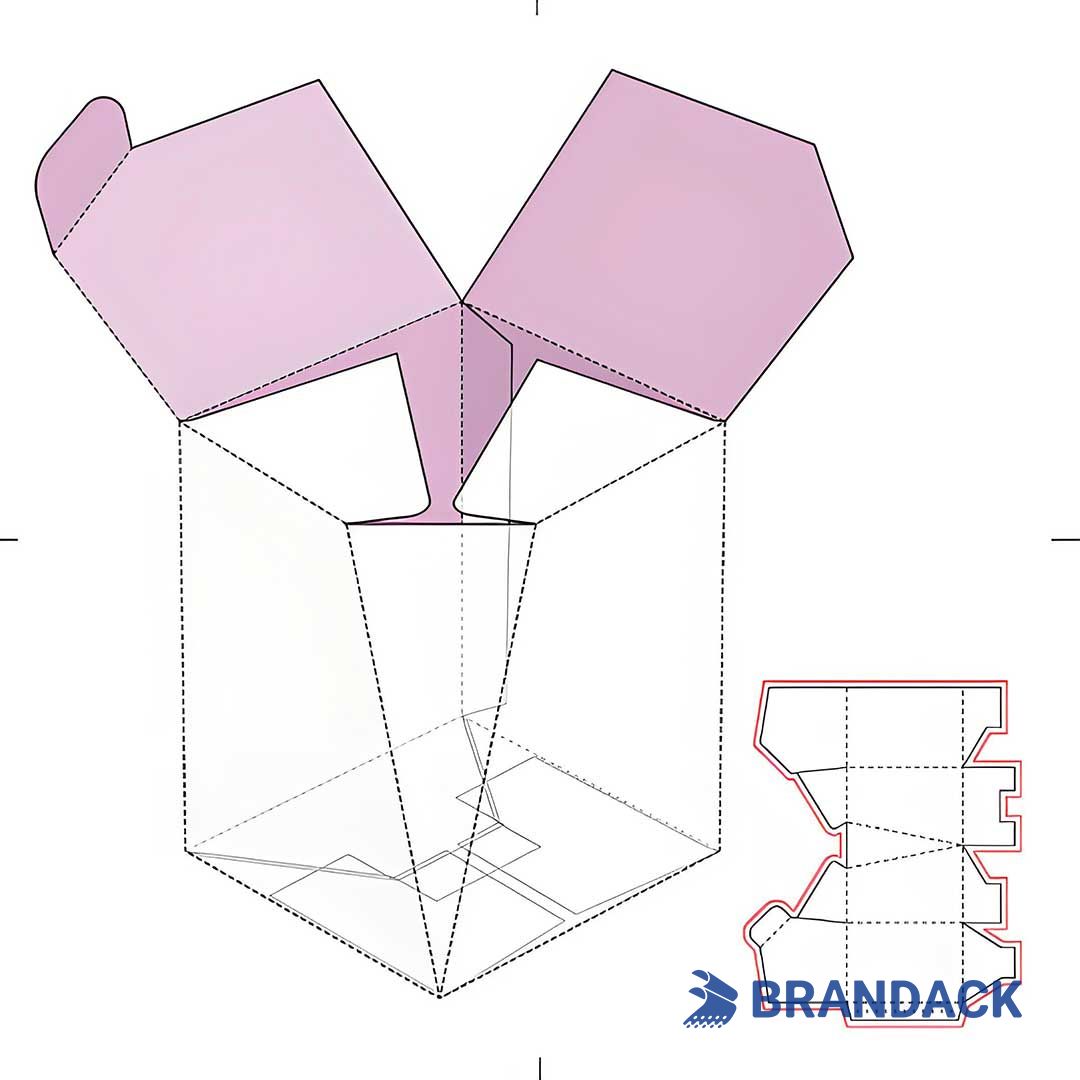

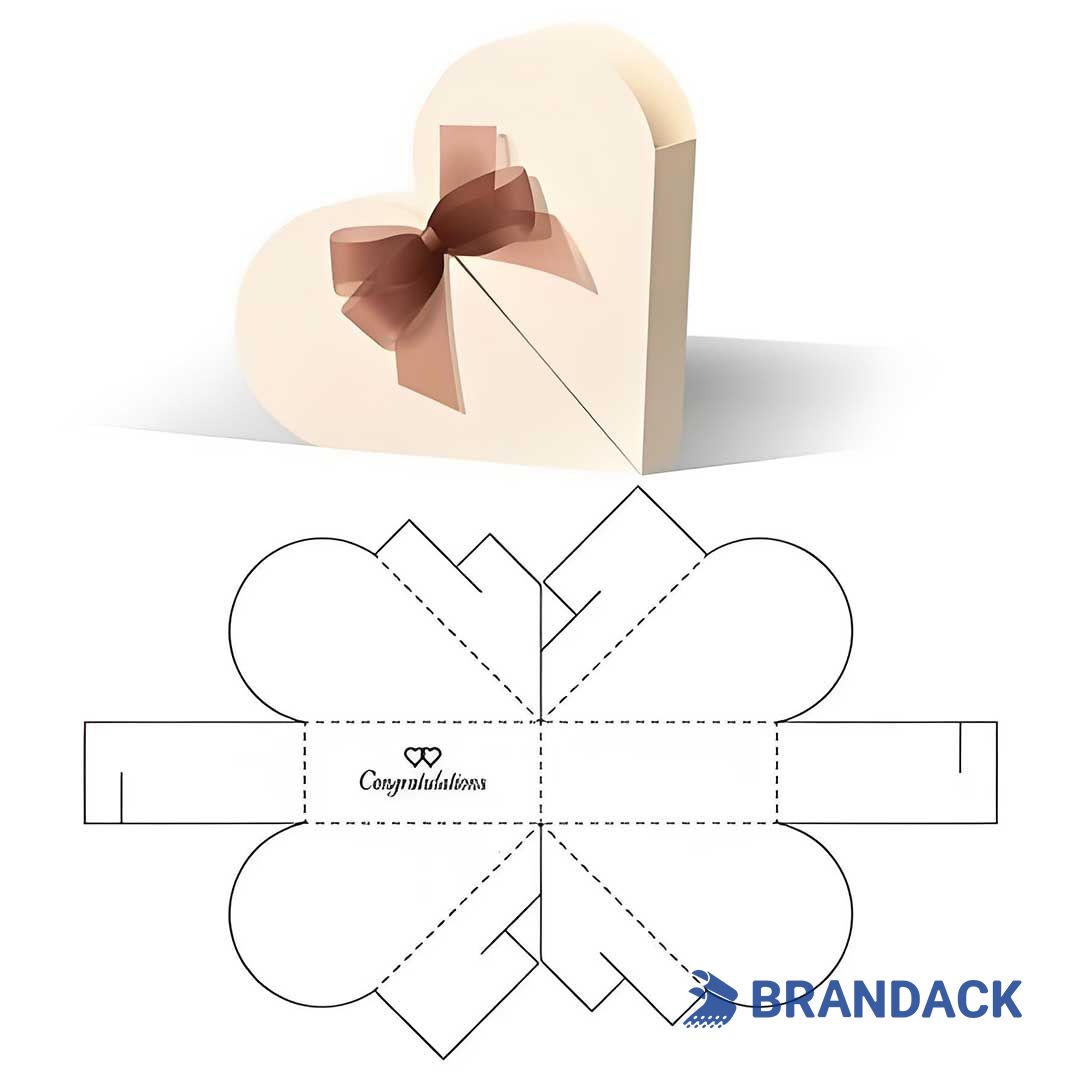

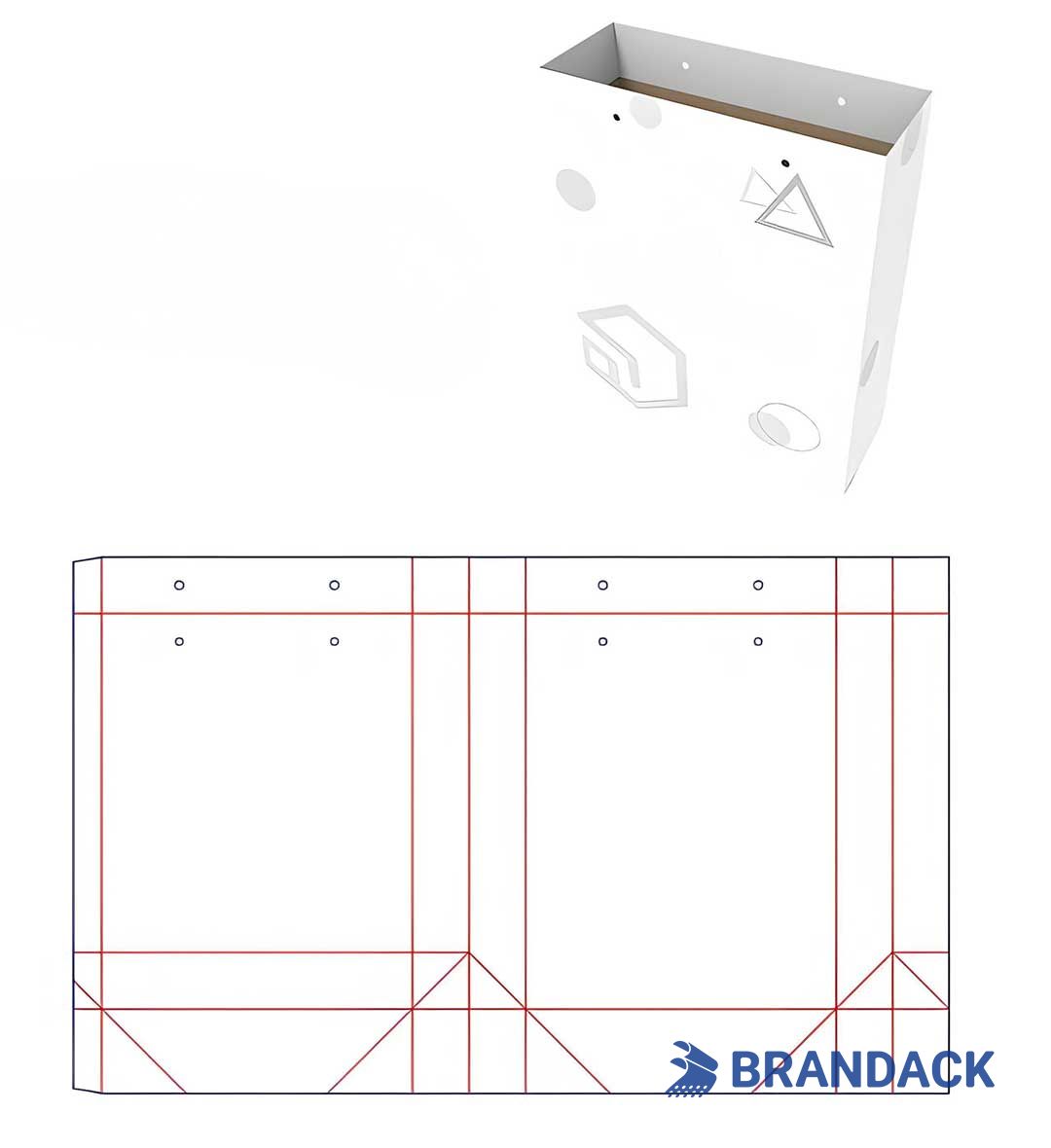

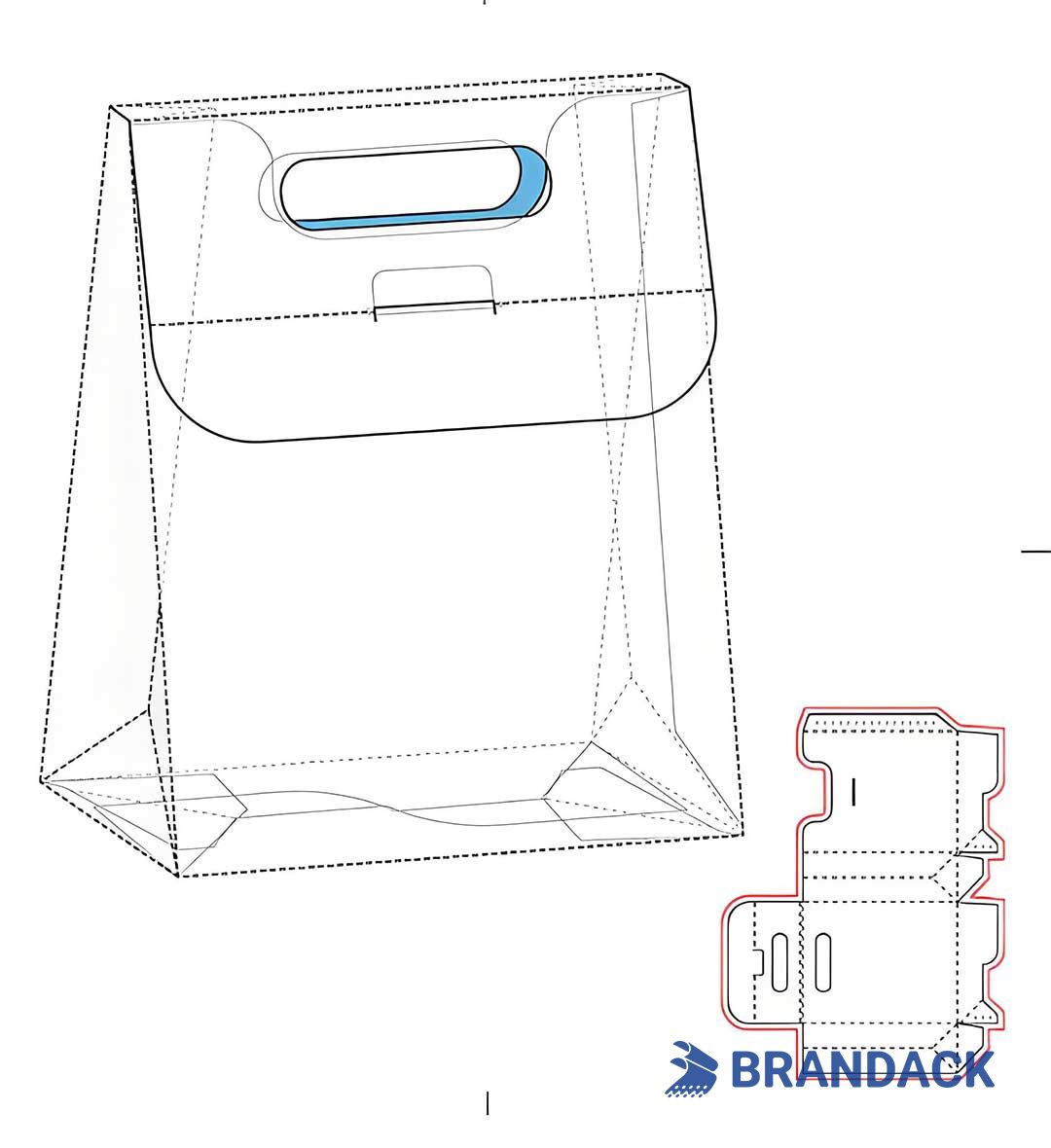

Trimming: Cut to final size with guillotines or die-cutters (tolerance ±0.5mm).

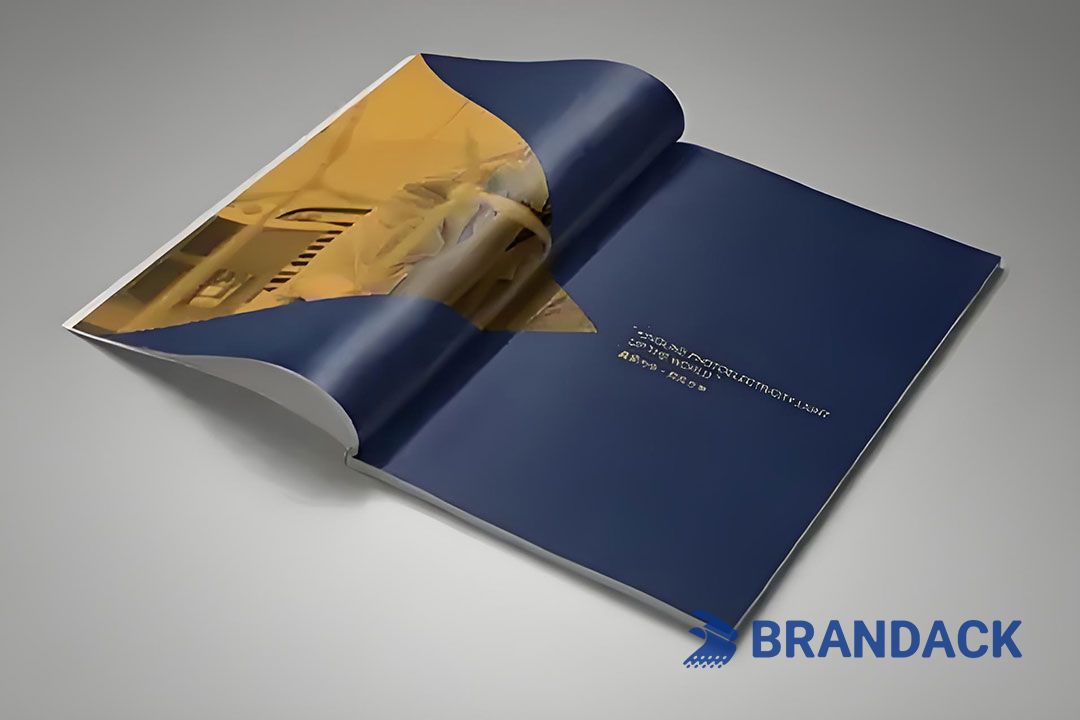

Enhancements: Add lamination (for durability), UV coating (for shine), embossing/debossing (for texture), or foil stamping (for luxury).

Assembly: Fold, glue, or stitch for boxes, brochures, or multi-panel packaging.

Quality Assurance (QA) in Lithographic Printing

QA is embedded in every stage to meet ISO 9001 standards and your expectations. Our process includes:

✅ Pre-Press QA

Automated File Audits: Tools like Adobe Acrobat Preflight detect missing fonts, low resolution, or color errors.

Hard Proof Validation: Physical proofs are printed on the same substrate as your final job - client sign-off is required to proceed.

✅ In-Press QA

Color Measurement: Spectrophotometers track ink density, ensuring consistency with the proof.

Registration Checks: Digital systems and 10x magnifiers keep plate alignment under 0.1mm (preventing blurry text/colors).

Ink Thickness Testing: Film gauges confirm layers are 2–5 microns (paper) or 5–8 microns (plastic) - avoiding smudging or fading.

Defect Inspections: Operators and cameras spot issues like ink spots, missing details, or substrate jams.

✅ Post-Press QA

Dimensional Checks: Calipers verify trimmed size and fold accuracy.

Finishing Tests: Lamination adhesion tests and fold durability checks ensure longevity.

Batch Sampling: 5% of the final order is inspected - any defects trigger a full review and rework if needed.

✅ Post-Delivery Support

We provide a QA report (with color data and inspection logs) for every order. If defects are found, we offer reprints or adjustments per our quality guarantee.

Why Choose Our Lithographic Printing Services?

Our team combines 20+ years of litho expertise with state-of-the-art equipment to deliver results that elevate your brand. We prioritize:

✦ Transparency: From prepress proofs to QA reports, we keep you informed at every step.

✦ Customization: Food-safe inks, recyclable substrates, and spot colors - we tailor the process to your needs.

✦ Reliability: 99.8% defect-free output, even for high-volume runs (e.g., 50,000+ packaging boxes).

Ready to bring your design to life? Contact our team today for a free consultation and quote - let’s create printing that stands out.

Precision in Every Print

We combine traditional expertise with innovative technology to deliver:

P Unbeatable print clarity and color fidelity

P Efficient handling of medium to large runs

P Customized solutions for packaging, retail, and corporate print needs

Whether you're a designer, brand manager, or print buyer, this Knowledge Base is designed to empower you with actionable insights - bridging creativity with technical excellence.

Have a project in mind? Reach out to our team for a consultation, and let’s create something impressive together!