In today’s fast-evolving packaging landscape, custom flexible packaging has become a cornerstone for brands aiming to differentiate products, enhance shelf appeal, and meet consumer demands for sustainability. Among the printing technologies powering this segment, flexographic printing (often called flexo printing) stands out for its versatility, efficiency, and ability to deliver high-quality results across diverse substrates. This knowledge base unpacks the essentials of flexo printing, its advantages for custom flexible packaging, key applications, emerging trends, and practical insights to guide your packaging decisions.

What Is Flexographic (Flexo) Printing Technology?

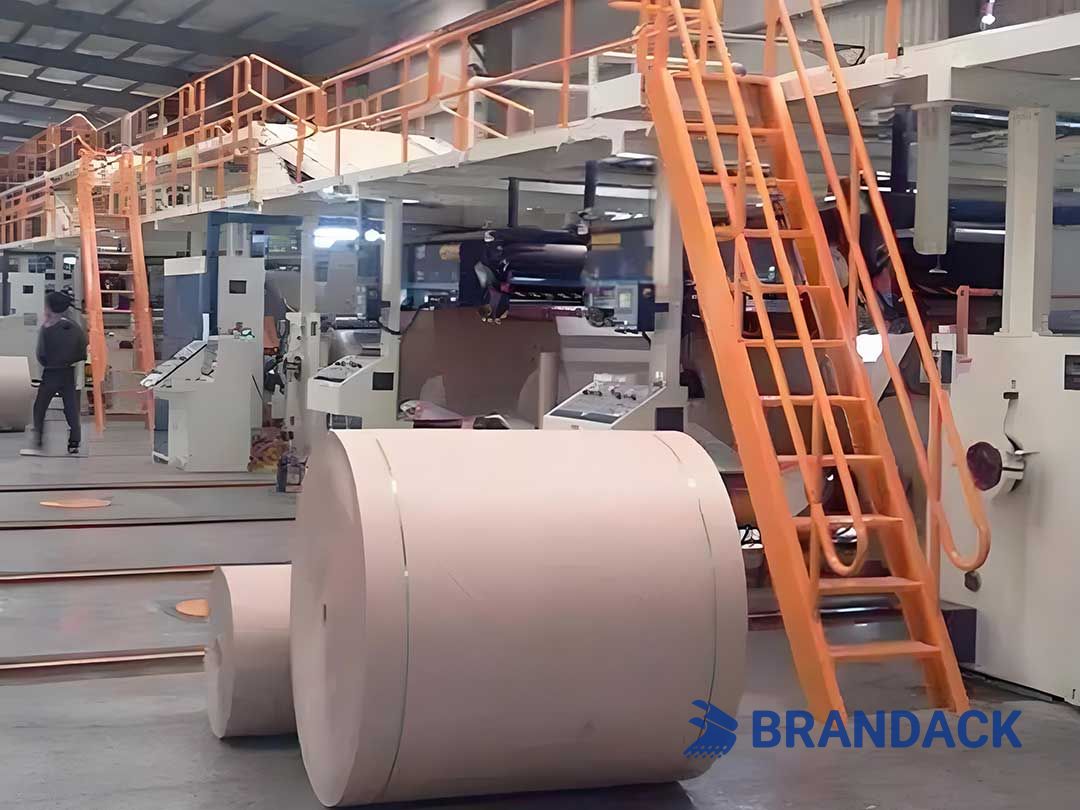

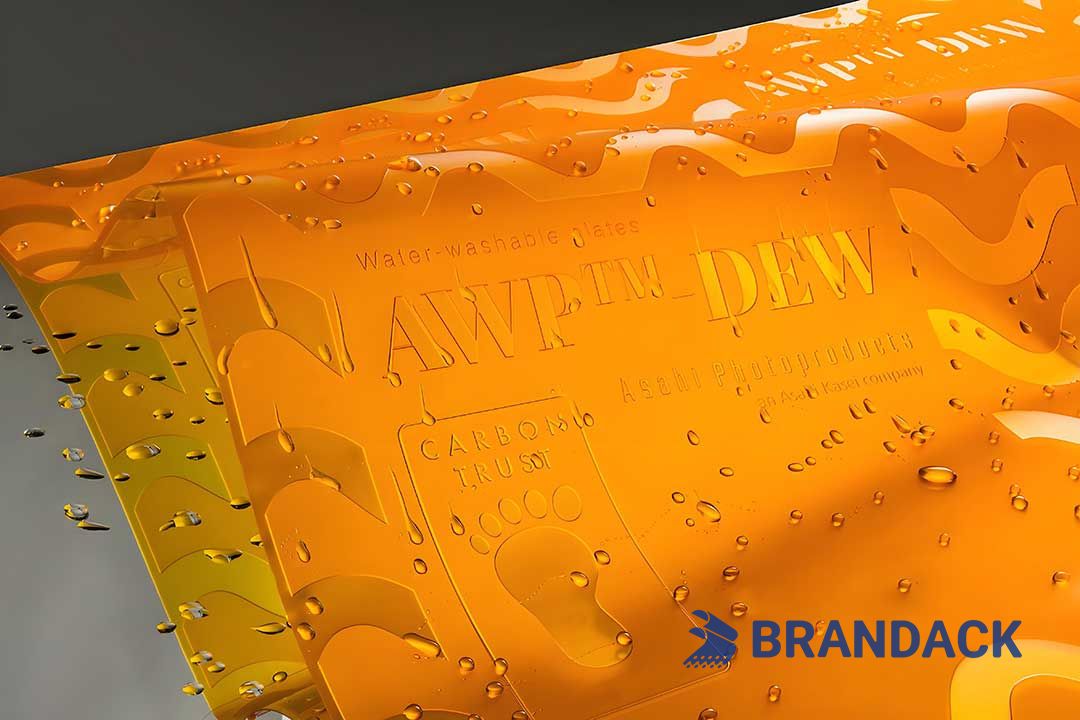

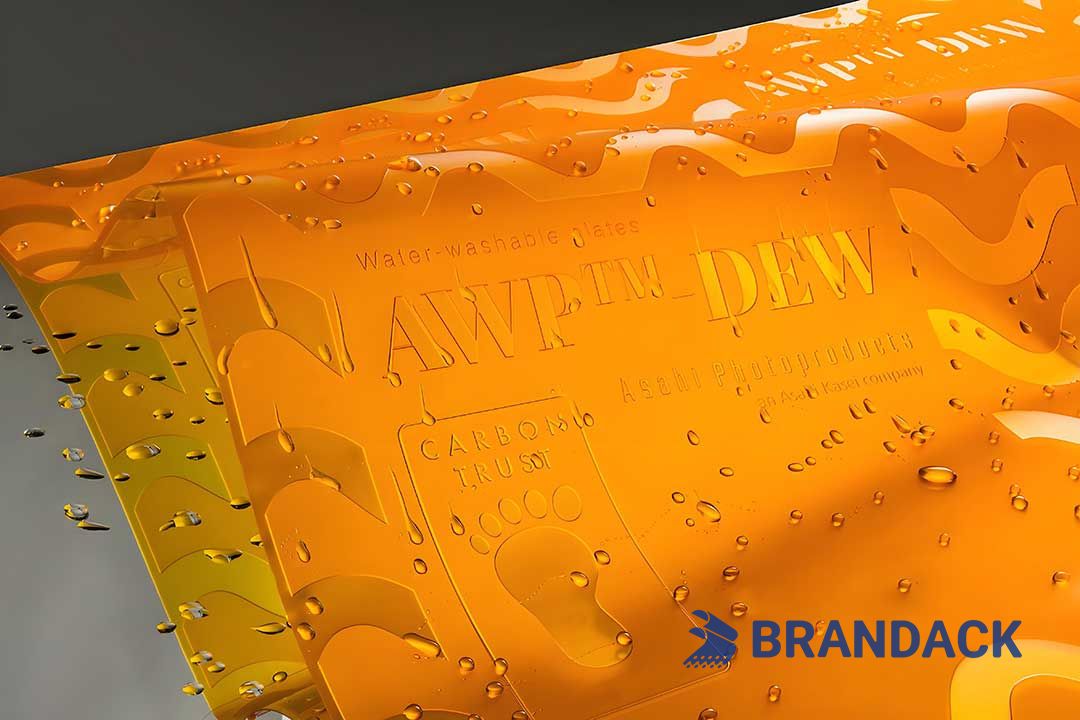

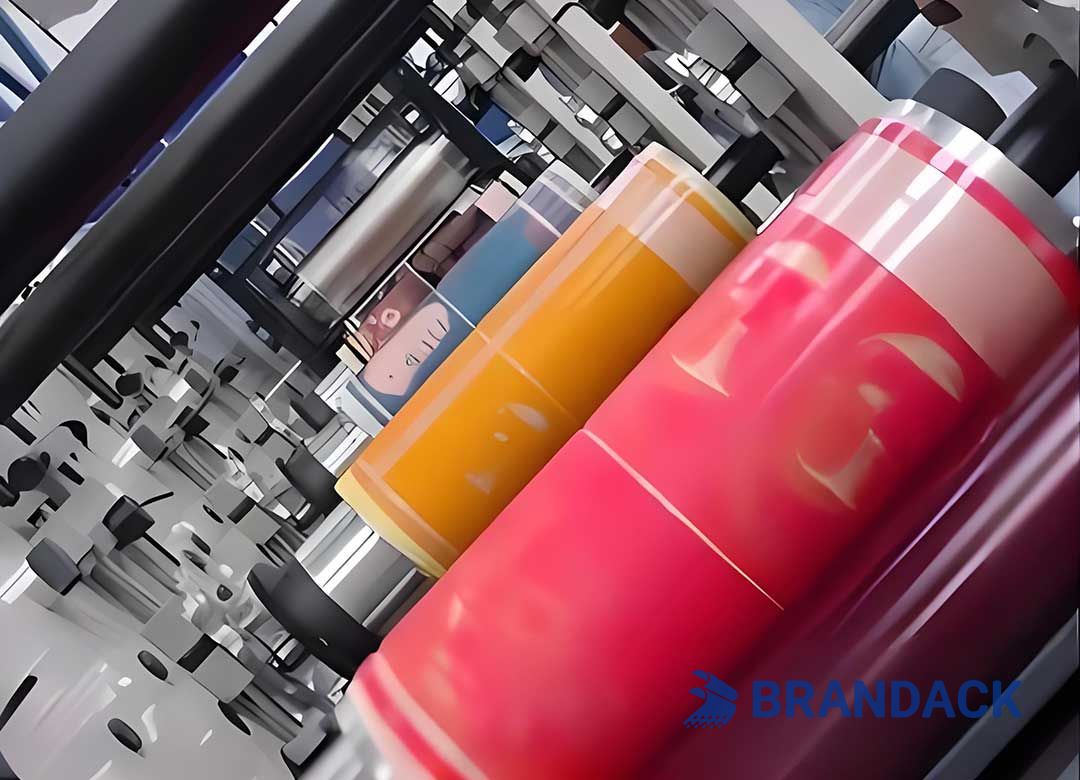

Flexo printing is a relief printing method built for speed, adaptability, and consistency - ideal for custom flexible packaging. At its core, it uses flexible polymer or rubber plates with raised images, mounted on rotating cylinders. Ink transfer is controlled by anilox rolls: precision-engineered rollers with microscopic cells that meter ink volume, ensuring even coverage across every print.

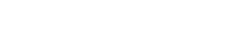

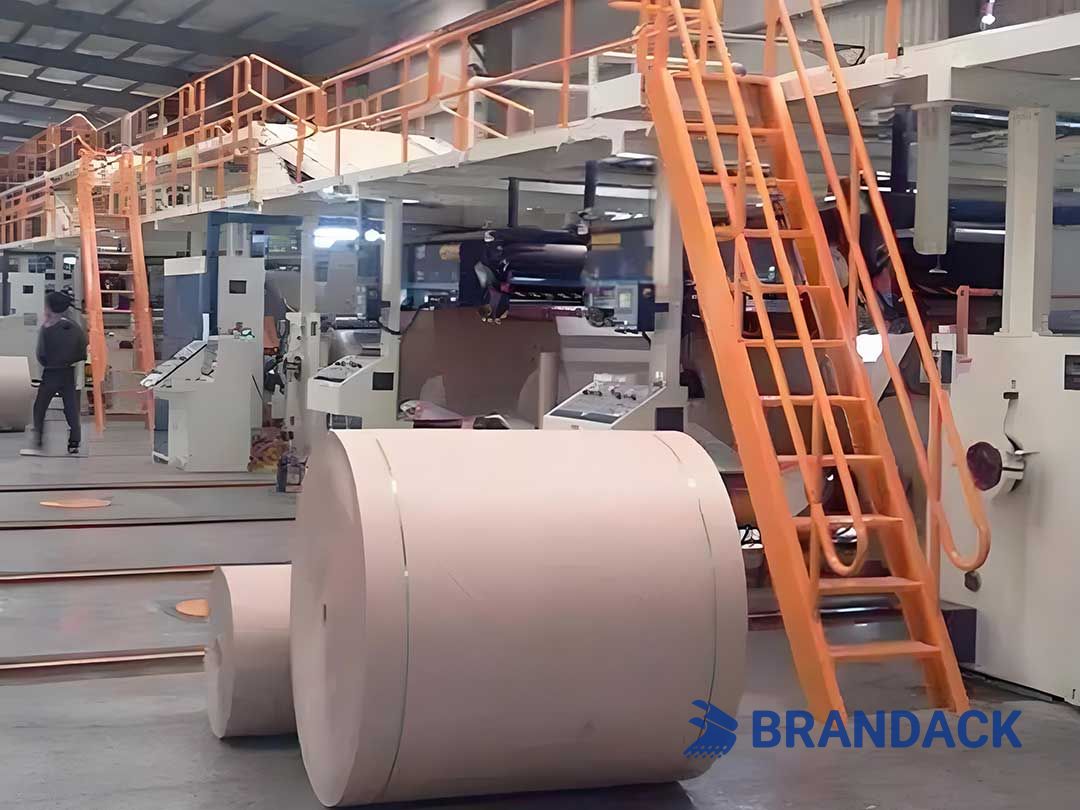

Unlike offset or gravure printing, flexo uses low-viscosity inks (aqueous, UV-curable, or low-VOC solvent-based) that bond seamlessly to flexible substrates like polyethylene (PE), polypropylene (PP), polyester (PET), laminates, and paper. The process works by pressing the inked plate against the substrate (held by an impression cylinder) in a continuous, high-speed operation - perfect for roll-fed materials used in custom pouches, wraps, and sachets. Modern advancements (e.g., digital plates, HD anilox rolls) have elevated flexo to rival gravure in image sharpness and color vibrancy.

Key Advantages of Flexo Printing for Custom Flexible Packaging

Flexo printing addresses the critical needs of brands - scalability, sustainability, and cost-effectiveness - making it a top choice for custom flexible packaging:

✅ Substrate Versatility: Unlike offset (limited to porous materials) or gravure (high setup costs for non-porous substrates), flexo adapts to nearly all flexible packaging materials. It works for thin snack wraps, durable stand-up pouches, and even moisture-resistant laminates, letting brands standardize on one technology for multiple formats.

✅ Sustainability Compliance: With global demands for eco-friendly packaging, flexo leads with water-based and UV-curable inks that emit fewer VOCs than solvent-based alternatives. Many flexo plates are recyclable, and the process generates minimal waste - aligning with FDA food-contact guidelines and brand sustainability goals.

✅ Cost & Speed Efficiency: Flexo has lower setup costs than gravure, making it accessible for small-batch custom orders (e.g., limited-edition products) and large-volume runs alike. Production speeds reach up to 2,000 feet per minute, cutting lead times - critical for seasonal campaigns or fast-moving consumer goods (FMCG).

✅ Consistent High Quality: Digital photopolymer plates and advanced anilox technology deliver crisp text, intricate graphics, and Pantone-matched colors. This ensures brand consistency across global packaging lines, even for complex designs.

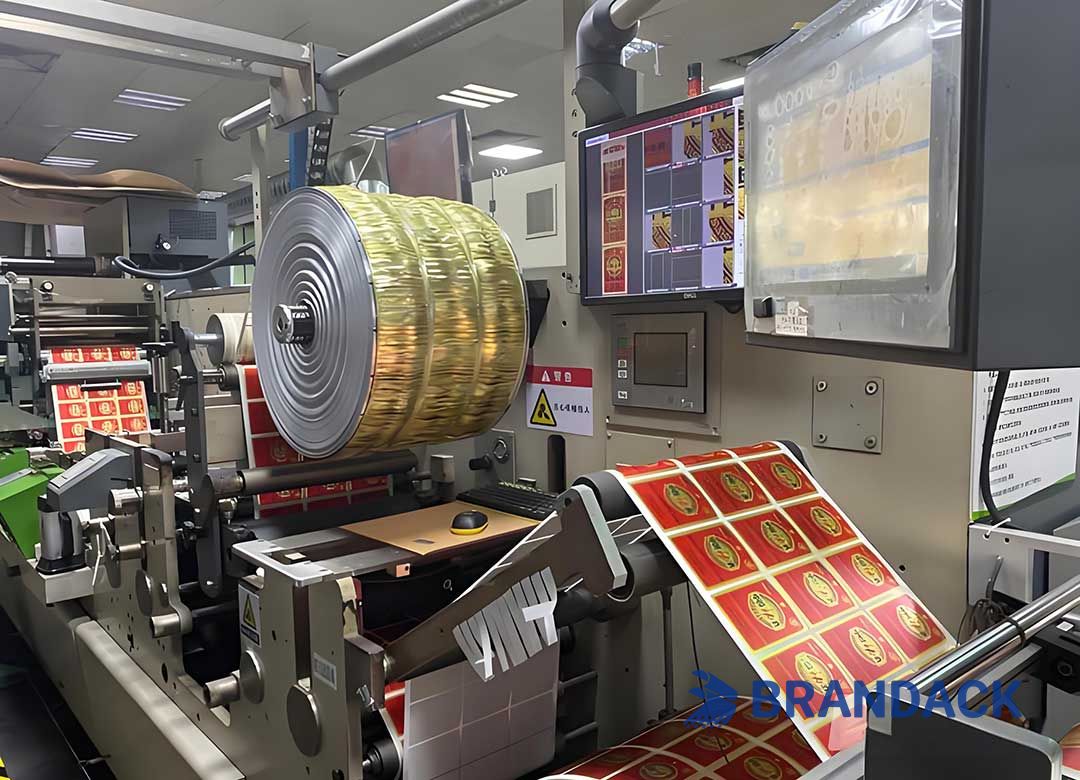

Our Custom Flexo Printing Process for Flexible Packaging

We’ve streamlined our flexo workflow to be collaborative, transparent, and tailored to your brand’s vision. Here’s how we bring your custom packaging to life:

✅ Design Consultation & Prepress: Our team works with you to refine artwork, optimizing it for flexo’s strengths (bold colors, clear details). We run prepress checks to adjust for substrate properties and ink adhesion, then share a digital proof for your approval.

✅ Precision Plate Making: Using Computer-to-Plate (CTP) technology, we create high-quality photopolymer plates. CTP eliminates film, reducing errors and setup time while ensuring sharp, consistent raised images.

✅ Press Setup & Trial Run: Plates are mounted on our flexo presses, anilox rolls calibrated for ink volume, and your chosen substrate loaded. A trial run tests color accuracy and substrate compatibility - we share physical samples for your final sign-off.

✅ Batch Production: With approval, we start high-speed production. Our operators monitor in real time to maintain quality, adjusting ink levels or tension as needed.

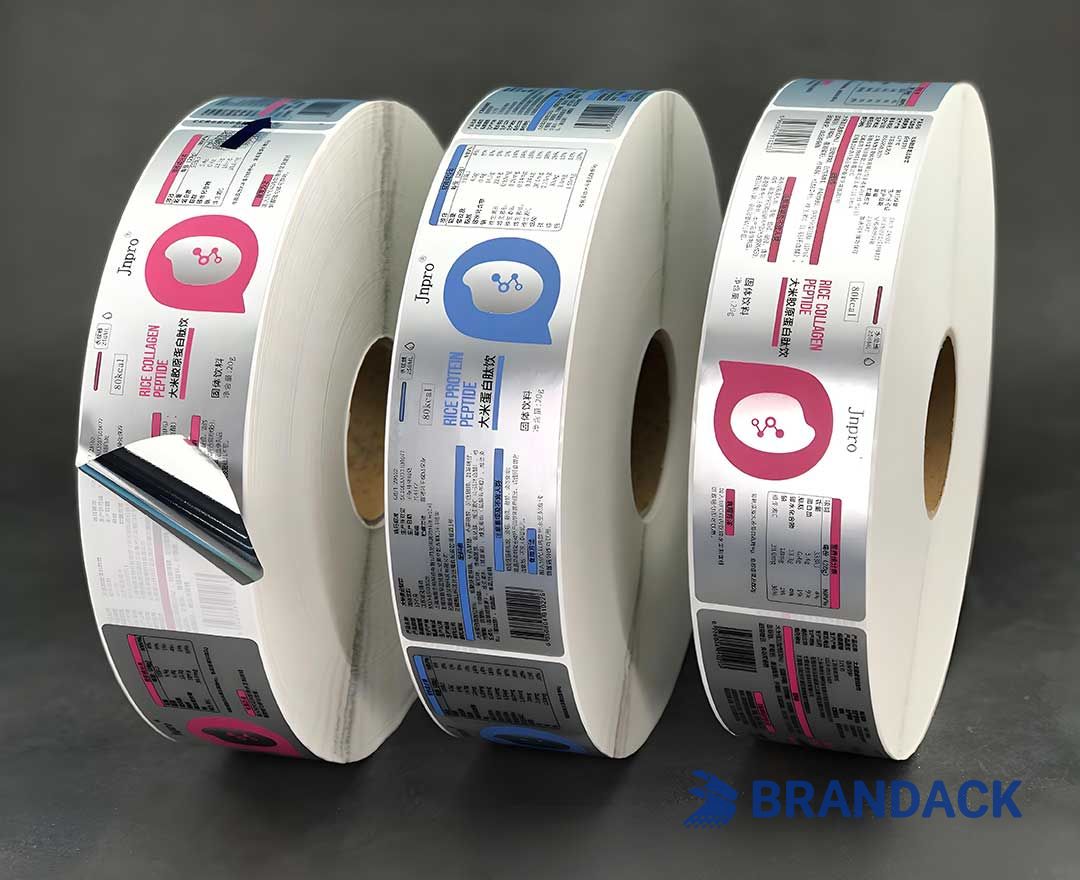

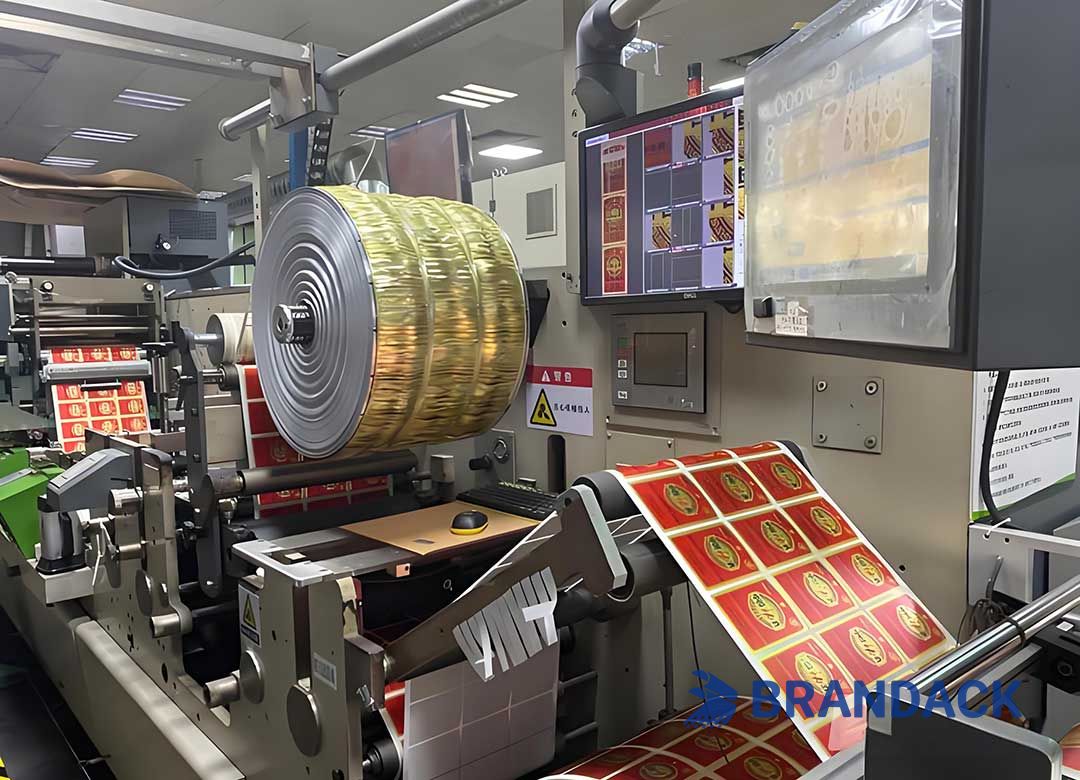

✅ Finishing & Quality Assurance: Post-printing, we add laminates (for barrier protection), die-cutting (to shape), or sealing (for pouches). Every batch undergoes rigorous checks - color matching, print sharpness, substrate integrity - to meet your specs and industry standards.

Top Applications of Flexo-Printed Custom Flexible Packaging

Flexo printing’s adaptability makes it indispensable across industries:

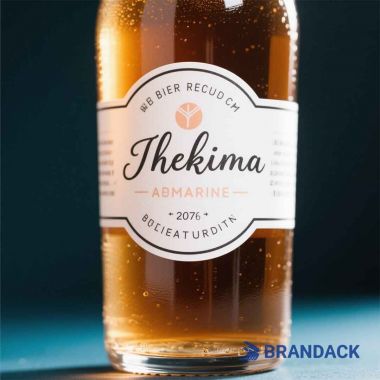

Food & Beverage: Snack pouches, cereal bags, frozen food wraps, and beverage labels rely on flexo’s FDA-approved inks and moisture-resistant substrate compatibility to preserve freshness.

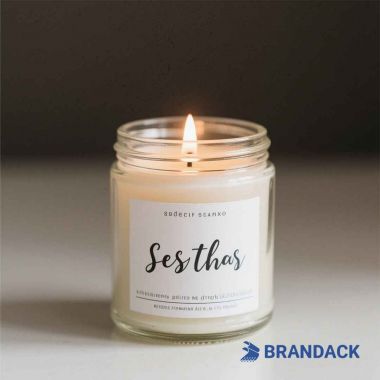

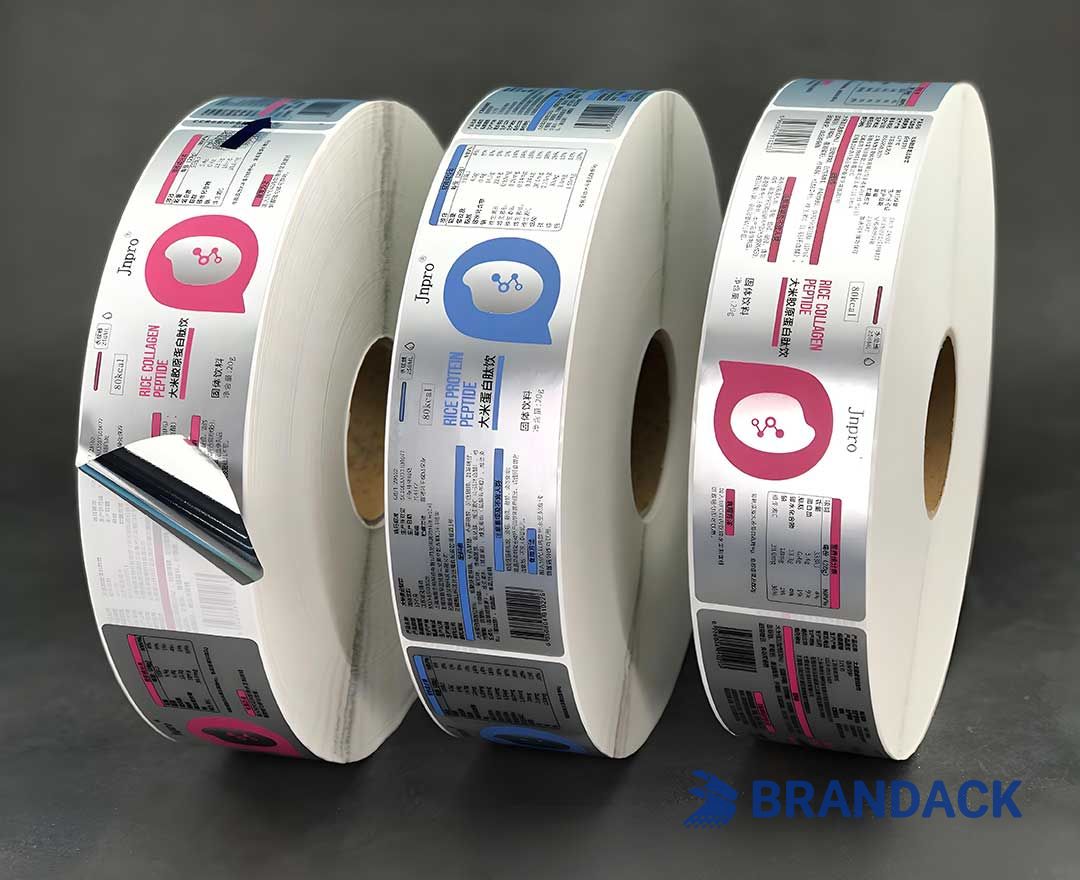

Personal Care: Cosmetics sachets, shampoo pouches, and makeup wipes use flexo for vibrant, glossy finishes (via UV inks) that boost shelf appeal.

Pharmaceuticals: Pill blister packs and surgical tape wrappers use flexo for precise text (dosage instructions) and compliance with strict healthcare regulations.

Household & Industrial: Laundry detergent pods, cleaning wipe containers, and industrial wraps benefit from flexo’s durable prints that resist fading in harsh environments.

Emerging Trends in Flexo Printing for Custom Packaging

The flexo industry continues to innovate, keeping pace with brand and consumer demands:

P Digital Flexo Integration: Cloud-based prepress and inline digital printing reduce setup time, enabling shorter runs (ideal for limited editions) and faster time-to-market.

P AI-Powered Quality Control: Inline cameras and machine learning detect defects (smudges, registration errors) in real time, cutting waste and ensuring perfection.

P Bio-Based Materials: Bio-inks (soy, algae-derived) and compostable substrates (PLA films) make flexo a leader in fully sustainable packaging.

P HD Flexo: Finer anilox rolls and advanced plates deliver gravure-quality details - perfect for premium packaging needing high-end aesthetics.

Frequently Asked Questions (FAQs)

Q: How does flexo compare to gravure?

A: Gravure offers great quality but high setup costs (metal cylinders) and long lead times (best for massive runs). Flexo has lower costs, faster turnaround, and broader substrate compatibility - modern HD flexo matches gravure quality for most uses.

Q: Is flexo safe for food contact?

A: Yes. We use FDA-approved water-based, UV-curable, or low-VOC inks, plus food-contact-certified substrates.

Q: What’s the minimum order quantity (MOQ)?

A: MOQs start at 5,000 units (ideal for startups/small brands), with volume discounts for large orders.

Q: How long is the lead time?

A: Standard orders take 7 - 10 business days; expedited service (3 - 5 days) is available for rush needs.

Q: Can flexo handle specialty finishes?

A: Absolutely - metallic inks, matte coatings, and spot UV are available as inline or post-press processes.

Why Choose Our Flexo Printing for Custom Flexible Packaging?

Our team combines decades of flexo expertise with state-of-the-art equipment to deliver packaging that elevates your brand. We prioritize sustainability, quality, and speed - whether you’re launching a new product or scaling production. Explore our portfolio, or contact us today for a design consultation. Let’s create custom flexible packaging that stands out on shelves and aligns with your goals.

✦ Superb Print Quality: Achieve sharp graphics, fine text, and consistent hues even on challenging surfaces.

✦ Eco-Friendly Innovation: Modern flexo utilizes water-based and UV-curable inks, reducing environmental impact.

✦ High-Speed Production: Ideal for tight deadlines and large volumes without sacrificing quality.

✦ Customization Freedom: Perfect for intricate designs, brand-specific colors, and unique shapes.

Empower Your Packaging Strategy

Leverage our expertise to create packaging that stands out on shelves, protects products, and aligns with your values. Flexo printing isn’t just a process - it’s a partnership between technology and creativity.

Dive deeper into the world of flexographic innovation. Let’s transform your vision into flexible packaging that resonates and performs.