In today’s competitive market, custom packaging is more than just a protective layer - it’s a brand’s first impression. Premium UV printing technology has emerged as a game-changer, bridging the gap between durability, visual impact, and sustainability for high-quality custom packaging. This guide breaks down how it works, its unmatched benefits, and why it’s the ideal choice for elevating your clients’ brand packaging.

What Is Premium UV Printing for Custom Packaging?

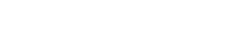

Unlike traditional offset or digital printing (which relies on air-drying or heat to set ink), premium UV printing uses ultraviolet (UV) light to instantly cure (harden) specialized UV-curable inks on contact with the packaging substrate. This process eliminates waiting time for drying and creates a bond that outperforms conventional inks - especially on non-porous or challenging materials common in custom packaging (e.g., plastic, metalized films, rigid cardboard, or recycled board).

Our premium UV printing setup enhances this core process with:

High-resolution print heads (up to 1200 DPI) for sharp text, intricate logos, and photo-realistic graphics.

LED UV curing systems (more energy-efficient and longer-lasting than traditional mercury lamps).

Food-safe, low-VOC (Volatile Organic Compounds) inks - critical for packaging in food, beauty, and medical sectors.

Unbeatable 5 Advantages for High-Quality Custom Packaging

Premium UV printing solves key pain points in custom packaging production while boosting end-product quality. Here’s how it delivers value:

1. Instant Drying = Faster Turnaround & Zero Smudging

UV inks cure immediately under UV light - no more waiting for ink to dry or risking smudges during post-printing processes (e.g., folding, laminating, or shipping). This cuts production lead times by 30–50% compared to traditional printing, making it perfect for time-sensitive projects (e.g., holiday gift sets, limited-edition product launches).

2. Superior Adhesion Across All Substrates

Custom packaging demands versatility - from matte cardboard boxes to glossy plastic tubes or metallic tins. Premium UV inks adhere seamlessly to both porous (paper-based) and non-porous (plastic, metal, glass) substrates, eliminating peeling, chipping, or fading even with frequent handling. For example, a cosmetic brand’s acrylic jar labels printed with UV technology will stay crisp through shipping and consumer use.

3. Vibrant, Long-Lasting Colors That Pop

UV inks deliver richer pigmentation and wider color gamuts than standard inks - think bold brand hues, deep blacks, and vivid gradients that stand out on store shelves. Unlike solvent-based inks, UV-cured colors resist fading from sunlight, moisture, or abrasion, ensuring packaging looks fresh from production to the consumer’s hands. This is a must for brands (e.g., beverage, toys) that rely on color to drive recognition.

4. Sharp Details & Textured Effects for Luxury Appeal

Premium UV printing supports intricate designs - from fine text (e.g., ingredient lists on skincare boxes) to embossed, matte, or glossy spot effects. Add-ons like UV varnish (for a sleek, scratch-resistant finish) or tactile textures (e.g., a soft-touch coating on a luxury perfume box) elevate perceived value, helping brands position products as high-end without extra cost.

5. Eco-Friendly & Cost-Effective

Modern UV inks contain minimal VOCs, reducing environmental impact and meeting global sustainability standards (e.g., FSC, FDA for food contact). Additionally, instant curing minimizes ink waste (no “dry-up” during setup) and eliminates the need for drying ovens - lowering energy use and operational costs. For clients focused on eco-friendly branding, this is a key differentiator.

Top Applications: Which Custom Packaging Benefits Most?

Premium UV printing shines across industries where quality, durability, and aesthetics matter. Here are its highest-impact use cases:

✅ Food & Beverage Packaging: Safe for direct contact with snacks, sauces, or beverages; resists grease and moisture (e.g., cereal boxes, craft beer cans, coffee pouches).

✅ Cosmetics & Personal Care: Supports glossy or matte finishes on plastic tubes, glass bottles, or cardboard compacts; ensures labels stay intact in humid bathrooms.

✅ Electronics Packaging: Durable enough for laptop sleeves, phone boxes, or accessory cases; resists scratches during shipping.

✅ Luxury & Gift Packaging: Creates tactile, high-gloss effects for perfume boxes, jewelry cases, or holiday gift bags - reinforcing premium brand identity.

✅ E-Commerce Packaging: Prints crisp logos and unboxing instructions on corrugated boxes or mailers; withstands rough transit without fading.

Why Partner with Us for Premium UV-Printed Custom Packaging?

Our expertise in premium UV printing goes beyond equipment - we tailor solutions to your clients’ unique needs:

✅ Customization Flexibility: Support small-batch runs (50+ units) for startups and large-scale production for enterprise brands.

✅ Quality Control: Every print undergoes color matching (via Pantone or CMYK) and durability testing (scratch, moisture, fade resistance) to ensure consistency.

✅ Sustainability Commitment: We use 100% recyclable UV inks and offer eco-friendly substrates (e.g., recycled cardboard) to align with green branding goals.

✅ End-to-End Support: Our team collaborates with clients from design (ensuring artwork optimizes UV printing) to delivery, reducing project stress.

Quick FAQs

Q: Can premium UV printing work on flexible packaging (e.g., plastic bags)?

A: Yes - we use flexible UV inks that bend without cracking, ideal for pouches or wraps.

Q: Is UV printing more expensive than traditional offset?

A: No - while upfront setup costs are similar, faster turnaround and lower waste make it cost-competitive for most projects.

Elevate Your Clients’ Brands with Premium UV Printing

In a world where packaging drives purchase decisions, premium UV printing turns custom boxes, labels, and bags into brand assets. It combines speed, durability, and sustainability to deliver high-quality results that help your clients stand out.

Explore our Knowledge Base for more resources (e.g., “Design Tips for UV-Printed Packaging” or “Sustainability Certifications for Custom Packaging”) or contact our team to request a sample of our premium UV printing work.