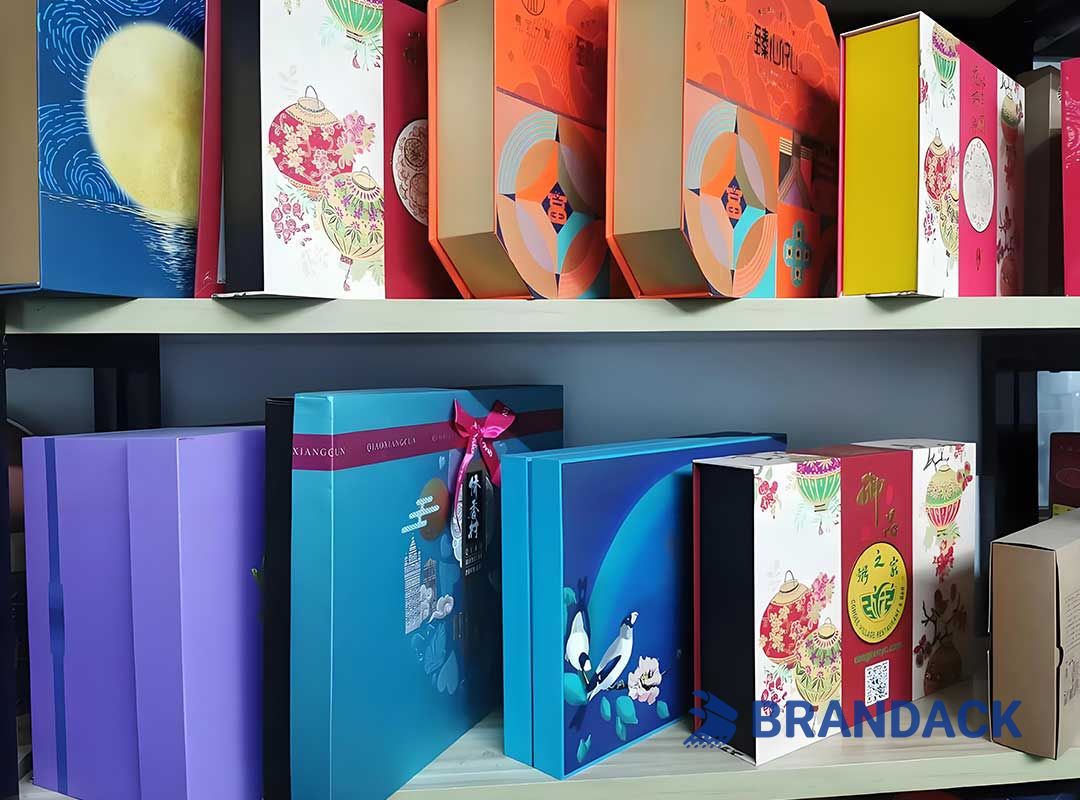

Welcome to your ultimate resource for seamless printing and packaging - where we turn creative concepts into durable, customer-ready solutions. Whether you’re a brand manager refining product packaging, a designer balancing aesthetics with production limits, or a small business launching your first custom print run, this Knowledge Base breaks down the end-to-end process. It cuts through confusion, prevents costly mistakes, and ensures your packaging shines: protecting products, engaging buyers, and meeting industry standards. Below, explore core tips to streamline your journey - with deeper insights waiting in the full Knowledge Base.

Design: Lay the Groundwork for Production Success

Design errors are the top cause of reworks - get these right first:

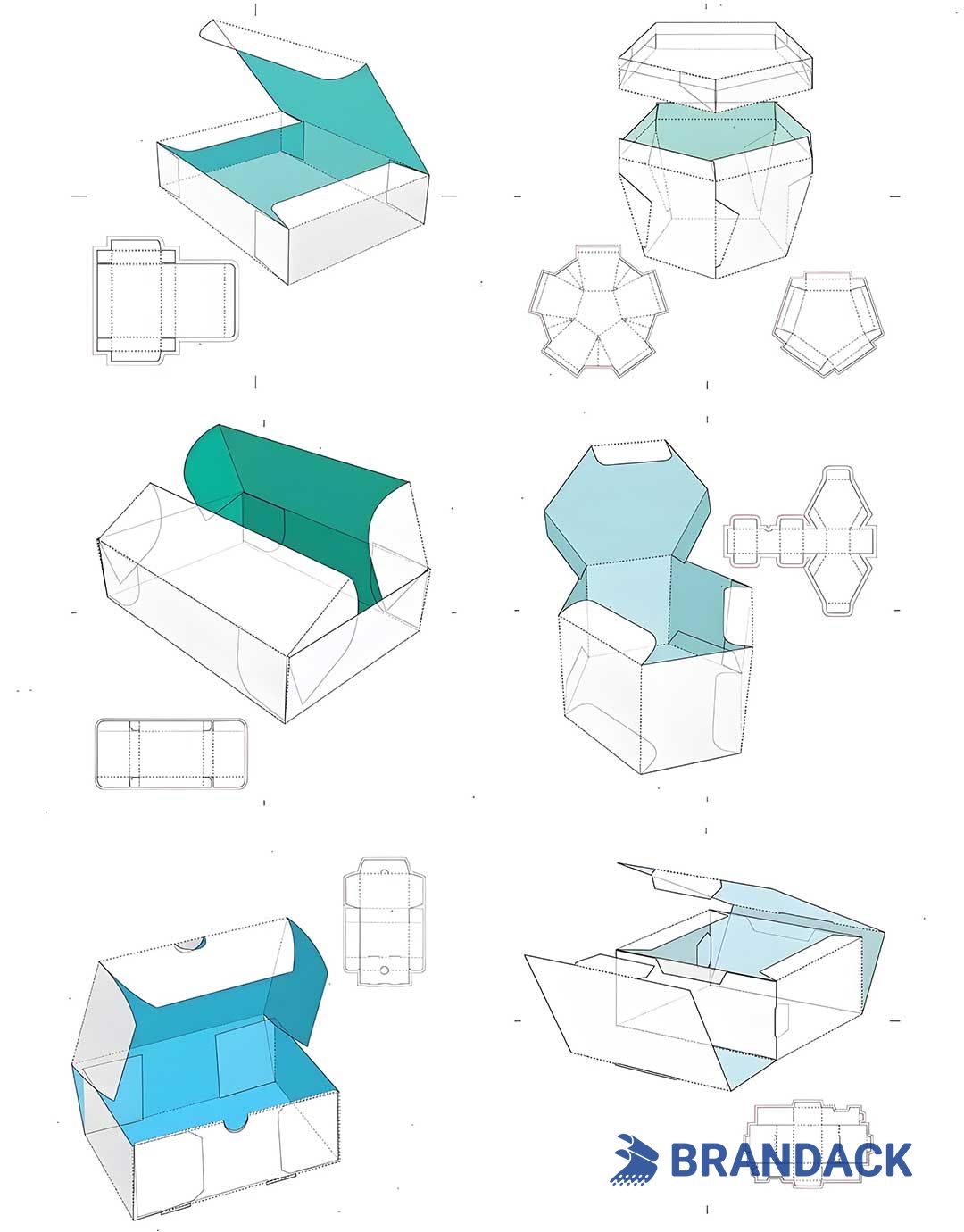

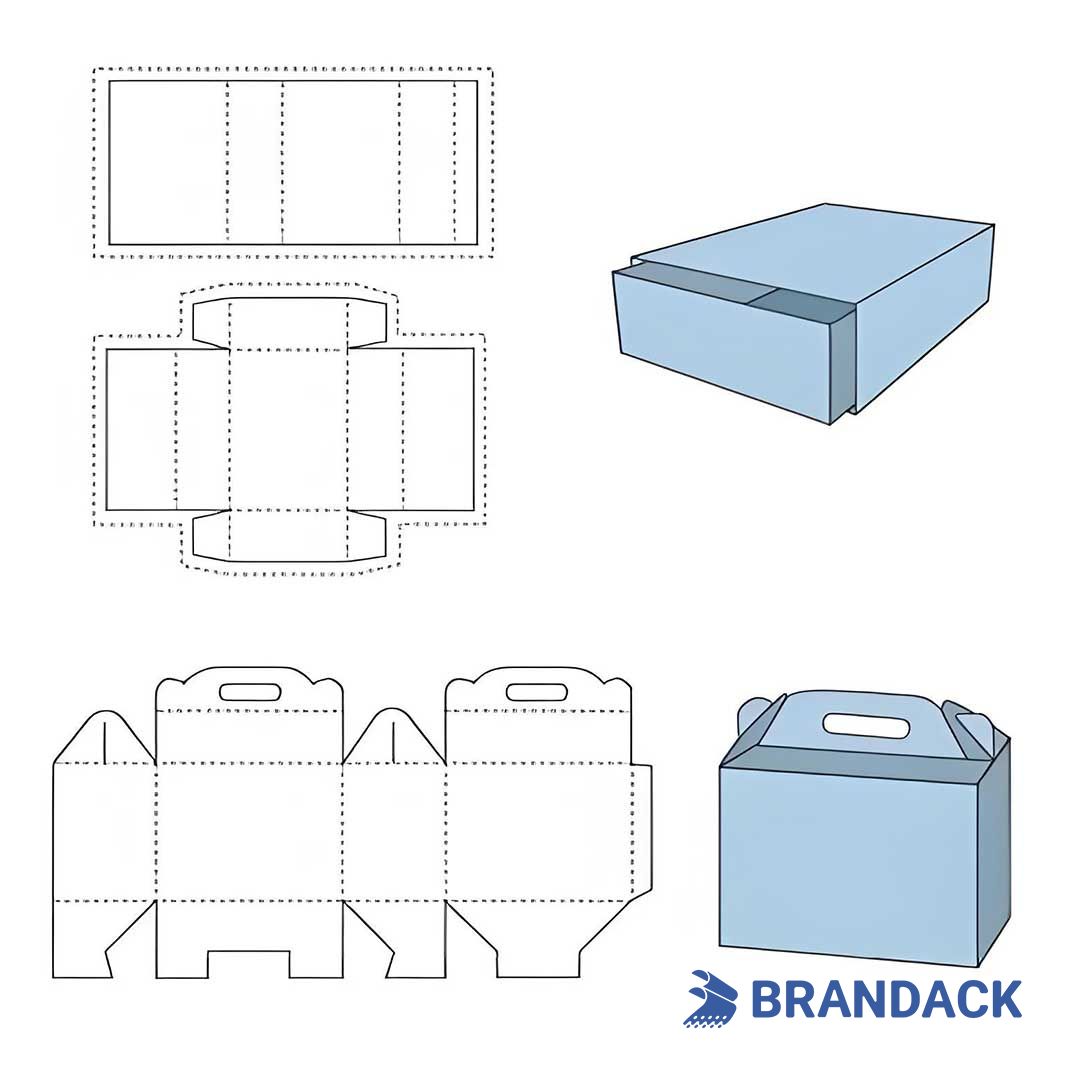

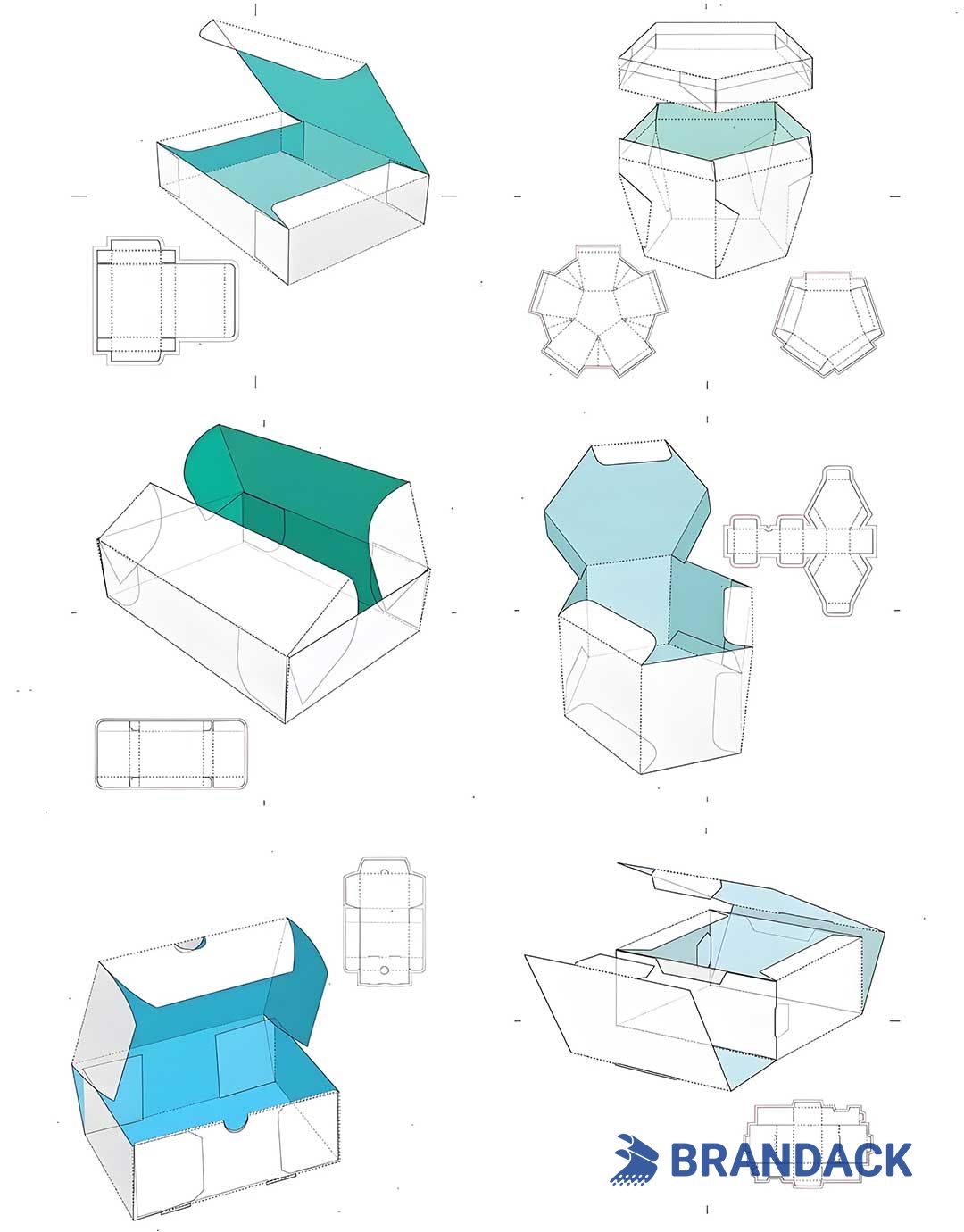

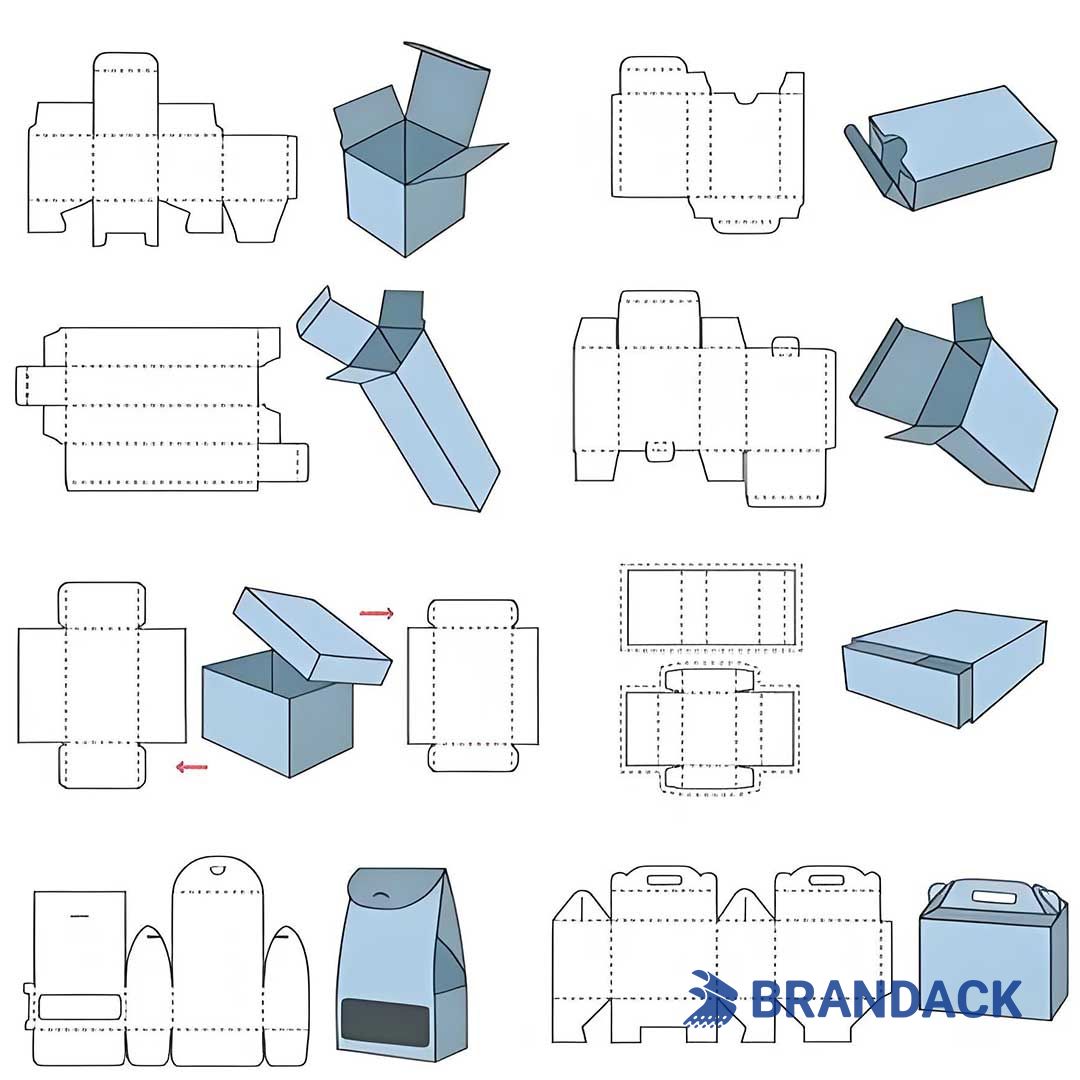

✅ Prioritize Production-Ready Dimensions & Bleed: Always include a 3mm bleed area (extra edge space) to avoid white borders if cutting shifts. Confirm trim sizes with your printer early; standard box styles (e.g., FOL, RSC) lower costs, while custom sizes need precise CAD files for equipment compatibility.

✅ Master Print-Friendly Color: Ditch RGB - print relies on CMYK (Cyan, Magenta, Yellow, Key/Black) for accuracy. Use Pantone (PMS) colors for brand consistency (e.g., logo shades) and test proofs on your final material (matte vs. glossy paper - textures change how colors look).

✅ Choose Legible Fonts & Scalable Graphics: Use vector files (AI, EPS) for logos/illustrations (they never blur, even for large prints like shipping boxes). For text: sans-serif fonts (Arial, Helvetica) work best for small sizes (8pt+); avoid script fonts under 8pt (they smudge easily). Embed all fonts to prevent "missing font" errors.

✅ Align Design with Material & Function: If packaging needs moisture resistance (e.g., food), design for laminates or coated papers - skip intricate patterns that trap dampness. For rigid luxury boxes, mark score lines (folding guides) to avoid creasing graphics.

✅ Include Mandatory Labels Early: Add barcodes, recycling symbols, or safety warnings (e.g., FDA for food, CE for EU) upfront. Ensure barcodes are scannable (test with a verifier) and leave space for these - last-minute additions force design compromises.

Production: Turn Designs into Physical Products

Production efficiency depends on matching tools, materials, and volume - here’s how to optimize:

✅ Pick Materials for Purpose & Cost:

Paperboard: Ideal for cosmetics/cereal boxes (lightweight, recyclable).

Corrugated cardboard: Best for shipping (durable, cushioning).

Plastic films (PET, PP): Perfect for snacks/pharmaceuticals (moisture-proof).

Ask about eco-friendly options (recycled paper, compostable plastics) - most printers now offer sustainable choices without quality loss.

✅ Choose the Right Printing Tech:

Offset Printing: Great for high volumes (10,000+ units) - sharp colors, low per-unit cost (best for paper/cardboard).

Flexographic Printing: Used for flexible materials (plastics, labels) - fast, works with water-based inks (eco-friendly).

Digital Printing: Perfect for small batches (100-500 units) or personalized packs (e.g., custom gift boxes) - fast turnaround, higher per-unit cost.

Consult your printer to match tech to your volume, material, and design.

✅ Never Skip Pre-Production Samples: Approve a physical sample first - check color accuracy, fit (does the product inside?), and durability (fold, seal, or stack tests). This sample becomes your "reference standard" for the full run.

✅ Streamline Workflows: Share files in PDF/X-1a (industry standard) to avoid conversion delays. Confirm lead times: offset takes 2-3 weeks (plate-making), digital 3-5 days. Align delivery with your product launch.

✅ Control Waste: Add 5-10% extra units to cover "make-ready" waste (initial test prints). Monitor the first hour of production - catch ink smudges or misalignment early to save hundreds of units.

Quality Control: Guarantee Consistency & Reliability

QC isn’t an afterthought - it’s built into every step. Define clear standards to avoid disappointing:

✅ Set Measurable QC Criteria: Agree with your printer on:

Appearance: No smudges, streaks, or uneven ink.

Dimensions: Trim size within ±0.5mm.

Function: Seams seal, zippers work, barcodes scan.

Color: Match PMS swatches (ΔE < 1.5 - ΔE measures color difference - for critical brand shades).

✅ Inspect In-Line & Post-Production:

In-Line: Printers should check samples every 15-30 minutes (automated vision systems spot misprints fast).

Post-Production: After folding/gluing, inspect 10-20% of the batch for structural flaws (weak seams, misfolded boxes).

✅ Use Precision Tools: Trust printers who use colorimeters (ink density), calipers (material thickness), and tensile testers (seal strength). Ask for QC reports - transparency builds trust.

✅ Agree on Defect Resolution: Define "defects" (e.g., smudges >5mm = unacceptable) and fixes:

Minor ( <5% flawed): Discount or reprint defective units.

Major ( >10% flawed): Full re-run at no cost.

Document issues with photos to speed up solutions.

✅ Follow Up Post-Delivery: Check units from different cartons - ensure consistency. Share feedback (good or bad) to help your printer refine future orders.

Explore More in the Full Knowledge Base

This guide is just the start. Inside the Knowledge Base, you’ll find:

P Detailed tutorials (e.g., "How to Create a Print-Ready PDF," "PMS Color Matching 101").

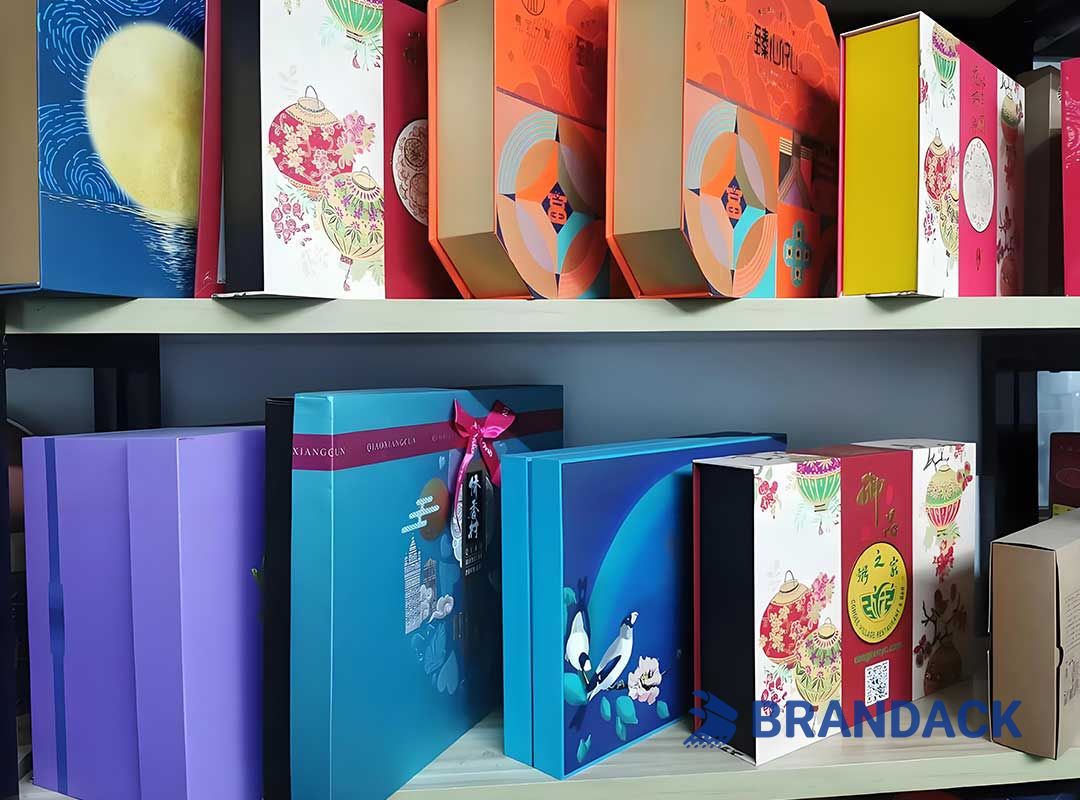

P Real-world case studies (e.g., "How a Bakery Cut Packaging Waste by 30%").

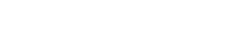

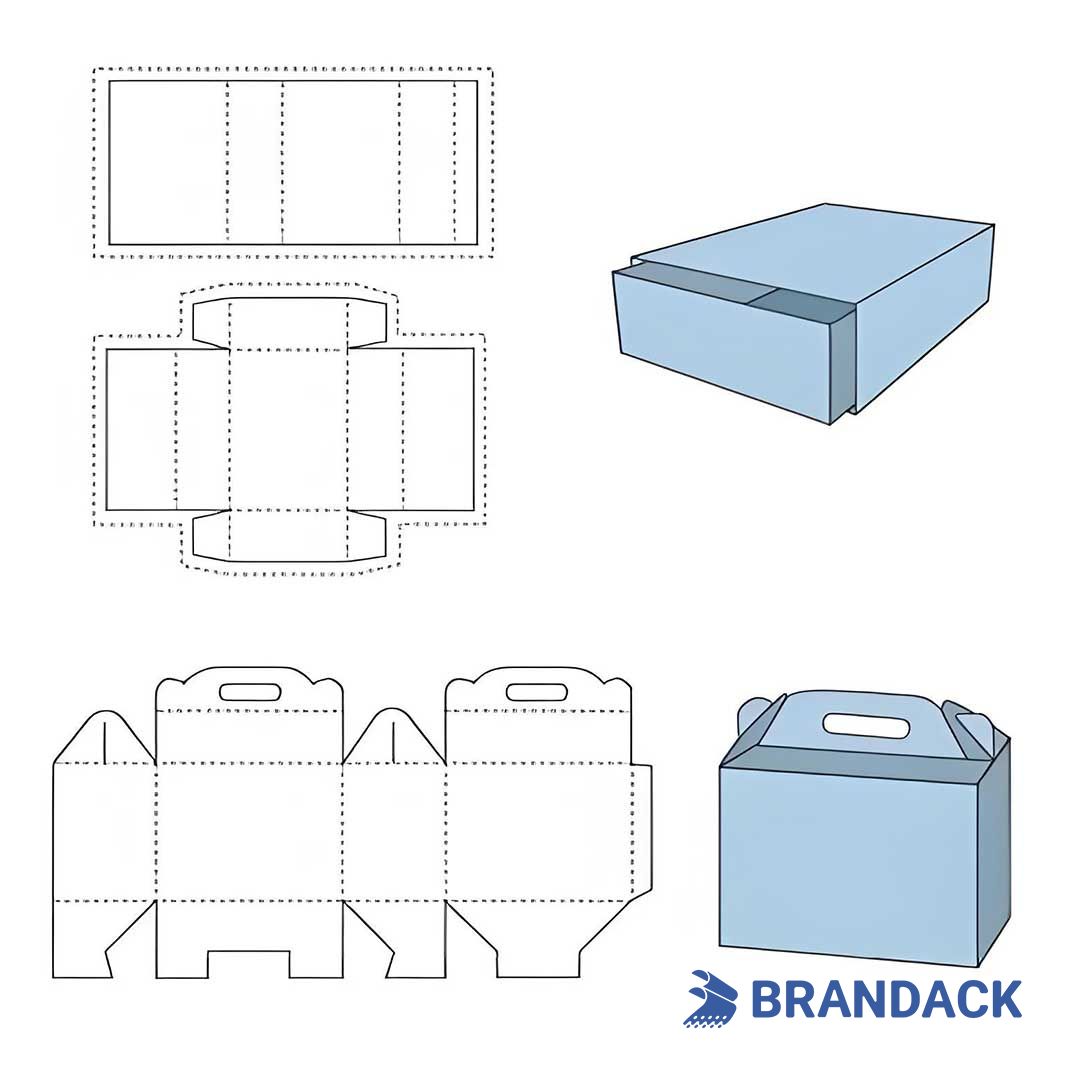

P Downloadable toolkits (standard box templates, barcode checklists, ink compatibility charts).

Whether you’re troubleshooting a specific issue or planning a new project, our Knowledge Base has actionable insights to save time and money.

Need personalized help? Our packaging experts are ready to discuss your goals, share samples, or refine your design. Let’s turn your packaging vision into a product that stands out together.